Nitrogen dioxide gas sensor containing petal-like SnSe2

A gas sensor, nitrogen dioxide technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of increased energy consumption, unsatisfactory gas characteristics, shortened service life, etc., to achieve small equipment investment and easy acquisition of raw materials , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

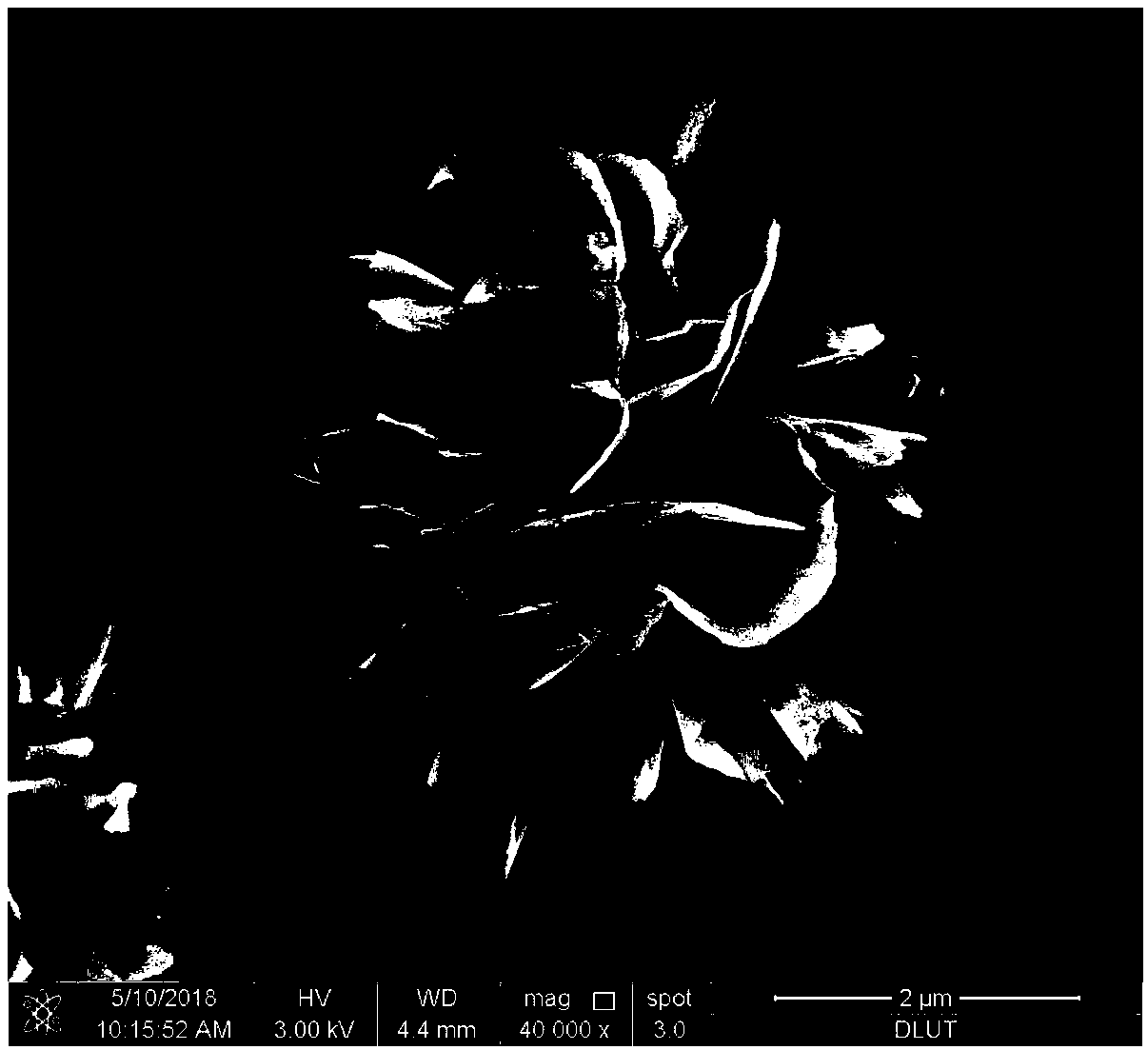

[0033] Petal-like SnSe 2 The nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The composition of the gas-sensing material is a petal-shaped tin diselenide nano-material prepared by a hydrothermal method. The leaves of the material grow loosely and evenly, and are in the shape of a curved sheet. The thickness of the leaf-like structure is about 45nm, and the particle size is about 0.8um. The preparation method comprises the following steps:

[0034] Step 1, 1.8mL C 2 h 8 N 2 , 34.2mL (CH 2 Oh) 2 Pour it into a 50mL beaker, add 406.2mg stannous chloride dihydrate and 142.1mg selenium powder, stir it magnetically for 20 minutes, pour it into a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, put it into a muffle furnace, and Heating at a speed of 3-5°C / min, the reaction temperature is 180°C, the reaction time ...

Embodiment 2

[0041] Petal-like SnSe 2 The nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The composition of the gas-sensitive material is a petal-shaped tin diselenide nanomaterial prepared by a hydrothermal method. The leaf surface of the material is smooth, the thickness of the leaf-like structure is about 60nm, the particle size is about 1.0um, and the particle size is about 1.5um. The preparation method comprises the following steps:

[0042] Step 1, prepare petal-shaped tin diselenide: 2.4mL 2 h 8 N 2 , 45.6mL (CH 2 Oh) 2 Mix, then add 541.6mg of stannous chloride dihydrate and 189.5mg of selenium powder, stir magnetically for 30 minutes and then pour into the reaction kettle for reaction. The reaction temperature is 180°C and the reaction time is 12 hours. Wash repeatedly with carbon disulfide-free solution, then with ionized wat...

Embodiment 3

[0046] Petal-like SnSe 2 The nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 1 μm. The composition of the gas-sensitive material is a petal-shaped tin diselenide nanomaterial prepared by a hydrothermal method. The leaves of the material have smooth surfaces but are of different sizes. The thickness of the leaf-like structure is about 40 nm, and the particle size is about 1.3 um. The preparation method comprises the following steps:

[0047] Step 1, prepare petal-shaped tin diselenide: 1.6mLLC 2 h 8 N 2 , 30.4mL (CH 2 Oh) 2 After mixing, add 361mg of stannous chloride dihydrate and 126.3mg of selenium powder, stir magnetically for 20min and then pour into the reaction kettle for reaction. The reaction temperature is 165°C and the reaction time is 3hh. Wash repeatedly with carbon disulfide-free solution, then with ionized water and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com