High-pressure common rail system oil inlet metering valve flow control system and control method

A technology of high-pressure common rail system and oil inlet metering valve, which is applied in electrical control, charging system, engine control, etc., and can solve problems such as model accuracy reduction, rail pressure oscillation, and insufficient responsiveness of proportional integral controllers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

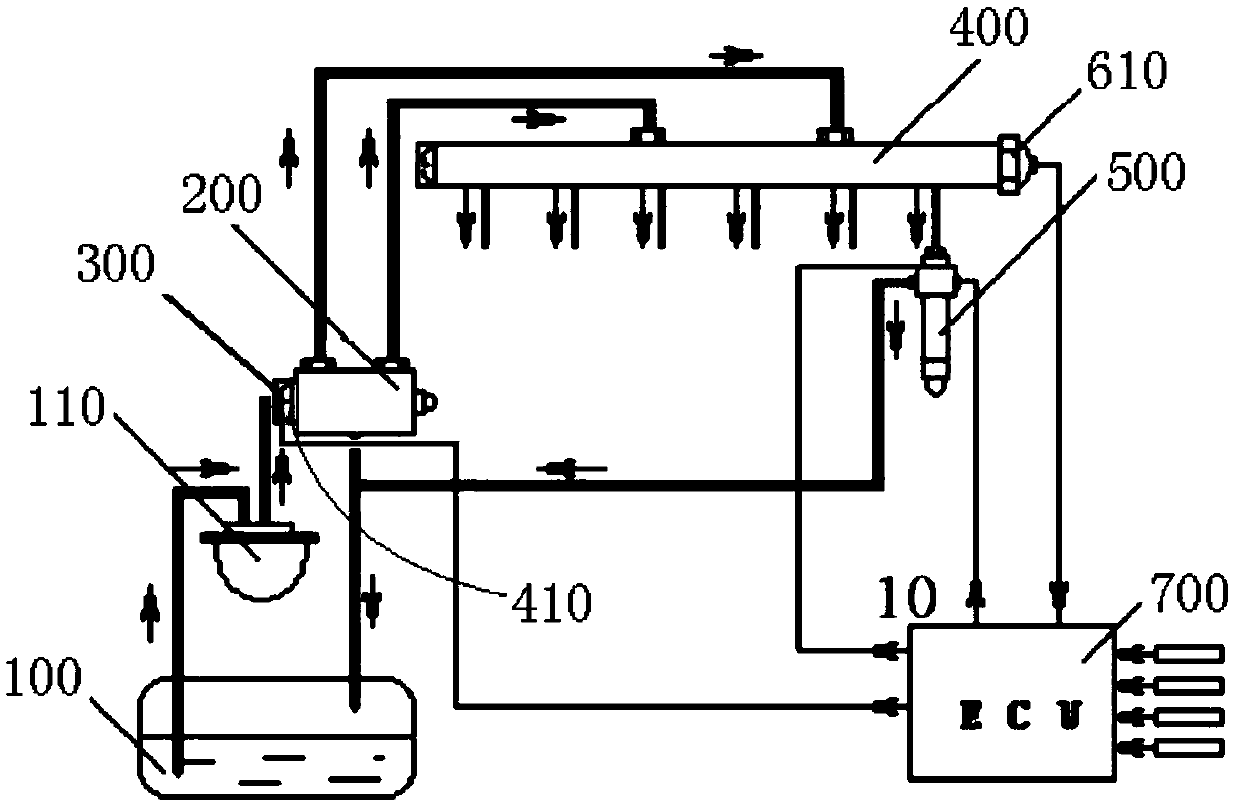

[0076] Such as figure 1 The shown high-pressure common rail fuel system includes a fuel tank 100 and a high-pressure fuel pump 200. The fuel tank 100 is connected to the fuel inlet meter 300 located on the fuel inlet of the high-pressure fuel pump 200 through a fuel filter 110. There is an overflow on the fuel inlet meter 300. The flow valve 410 is connected to the oil tank 100 . The oil outlet of the high-pressure oil pump 200 is connected to a common rail pipe 400, which acts as a pressure accumulator. The oil return port of the oil device 500 and the overflow valve 410 can send excess low-pressure diesel oil back to the oil tank 100 . A rail pressure sensor 610 is installed on the common rail pipe 400 , and the entire common rail fuel system is provided with a fuel temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com