A method for fermenting and extracting and purifying L-leucine

A technology of leucine and fermented liquid, applied in the direction of chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of high product cost, low efficiency, large demand for personnel, etc., and improve production efficiency, increase fermentation yield, and optimize the effect of fermentation culture steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for fermenting and extracting and purifying L-leucine, comprising the steps of:

[0029] Components of the fermentation medium: glucose 50g / L, (NH 4 ) 2 SO 4 10g / L, corn syrup 10g / L, KH 2 PO 4 4g / L, MgSO 4 ·7H 2 O 1.5g / L, citric acid 0.5g / L, MnSO 4 ·H 2 O 10mg / L, FeSO 4 ·7H 2 O 0.1g / L, V B1 5mg / L, V H 0.1mg / L.

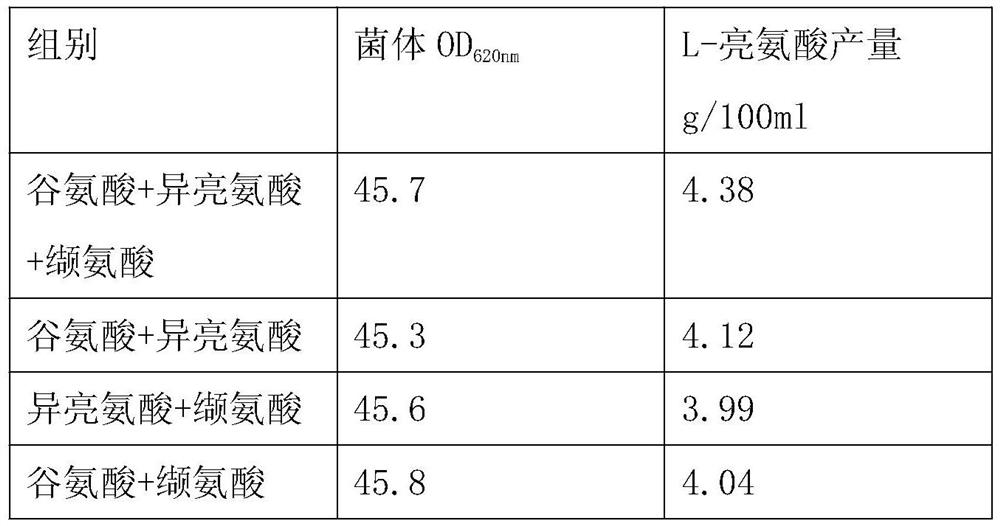

[0030] The components of the compound amino acid solution: glutamic acid 10g / L, isoleucine 5 / L, valine 5g / L,

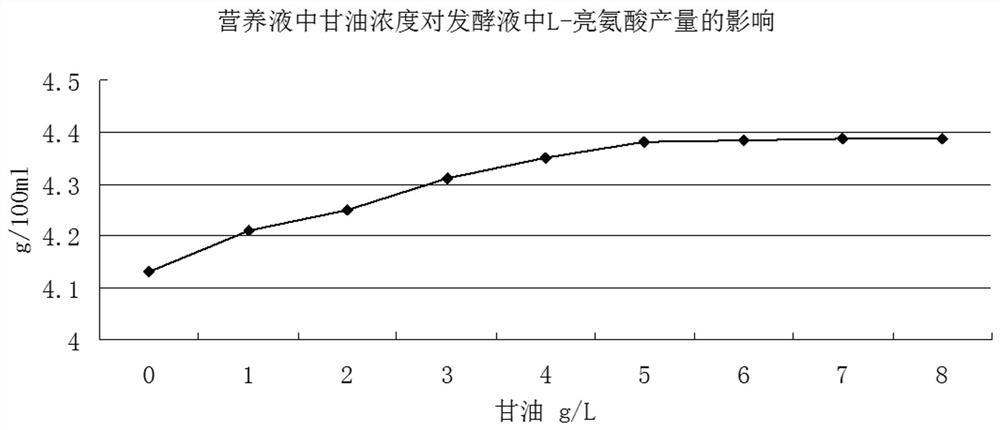

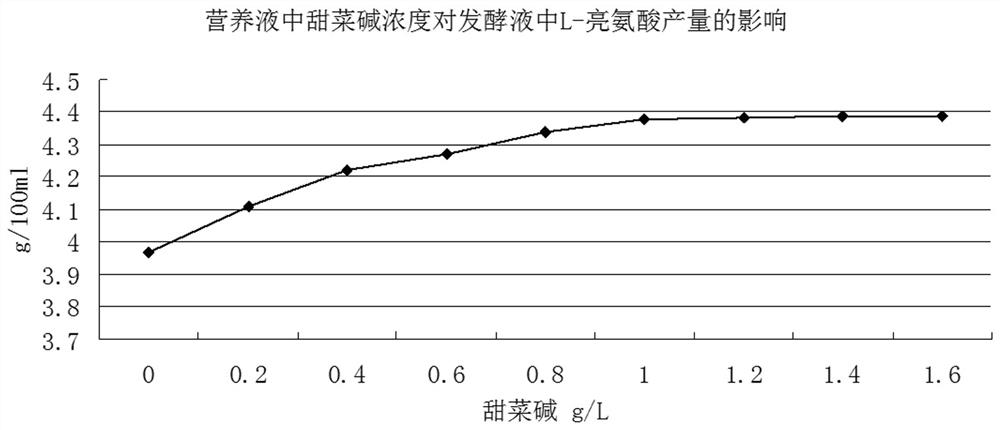

[0031] Components of nutrient solution: glucose 100g / L, glycerin 5g / L, betaine 1g / L;

[0032] Step 1) Taking Corynebacterium glutamicum CGMCC No.7033 as an example, the seed solution (OD 600 value is 9.5) into the fermentation medium, the culture temperature is 36.8°C, the pH of the medium is controlled by adding 20% ammonia water automatically to be 7.2, and the dissolved oxygen is controlled at 25% by stirring and ventilation; when the fermentation reaches 12h, the compound Amino acid solution is fed into the tank to maintain...

Embodiment 2

[0037] A method for fermenting and extracting and purifying L-leucine, comprising the steps of:

[0038] Components of the fermentation medium: glucose 50g / L, (NH 4 ) 2 SO 4 10g / L, corn steep liquor 10g / L, citric acid 0.5g / L, KH 2 PO 4 4g / L, MgSO 4 ·7H 2 O 1.5g / L, MnSO 4 ·H 2 O 10mg / L, FeSO 4 ·7H 2 O 0.1g / L, V B1 5mg / L, V H 0.1mg / L.

[0039] The components of the compound amino acid solution: glutamic acid 10g / L, isoleucine 5 / L, valine 5g / L,

[0040] Components of nutrient solution: glucose 100g / L, glycerol 5g / L, betaine 1g / L;

[0041] Step 1) seed solution (OD) with 8% inoculum 600 value is 9.5) into the fermentation medium, the culture temperature is 37.0°C, the pH of the medium is controlled by adding 20% ammonia water automatically to 7.1, and the dissolved oxygen is controlled at 30% by stirring and ventilation; when the fermentation reaches 12h, the compound Add the amino acid solution into the tank to maintain the concentration of glutamic acid in the t...

Embodiment 3

[0045] Effects of fermentation factors on L-leucine production and cell biomass in fermentation broth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com