Multiferroic sosoloid ceramic and preparation method thereof

A solid solution, multiferroic technology, applied in the field of multiferroic solid solution ceramics and its preparation, can solve the problems of large ceramic loss and low magnetoelectric coupling effect, and achieves reduction of loss, improvement of magnetic and magnetoelectric coupling effect, low loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

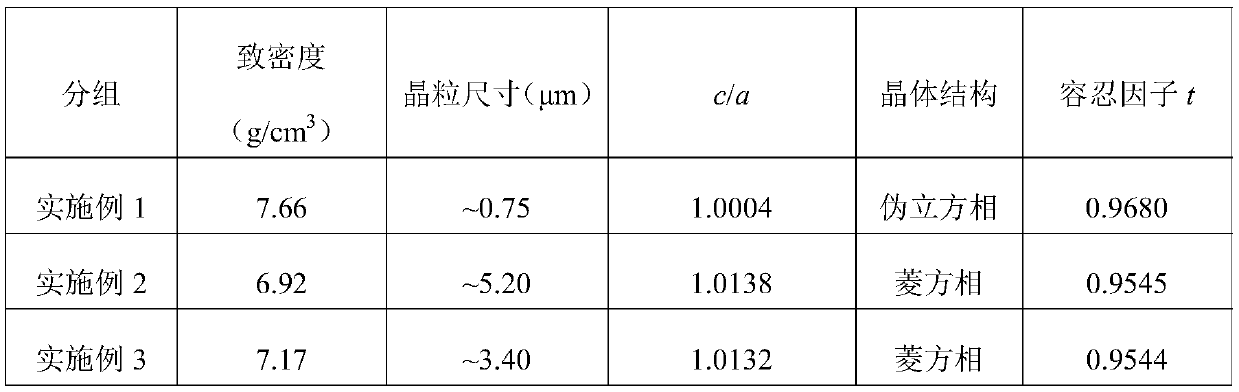

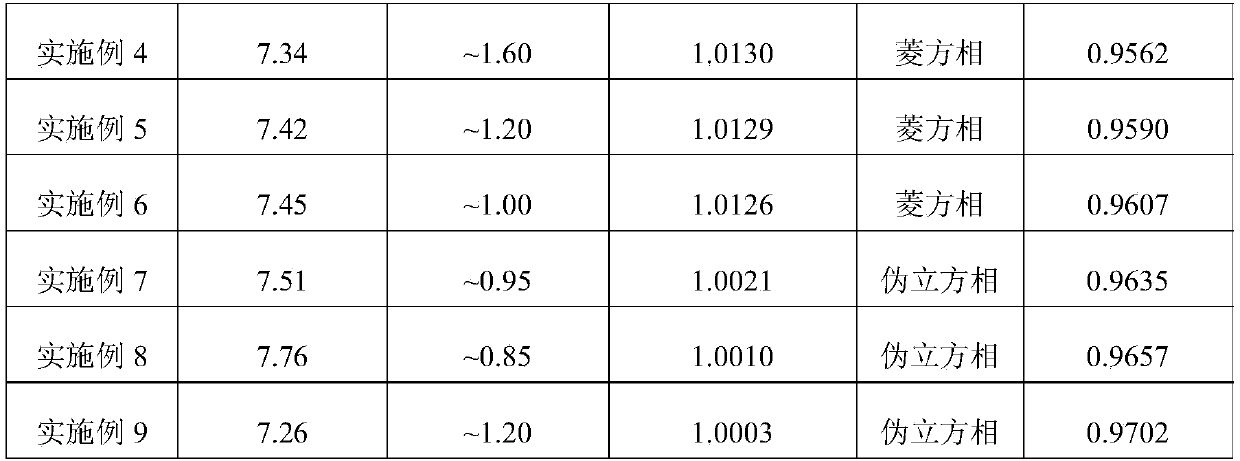

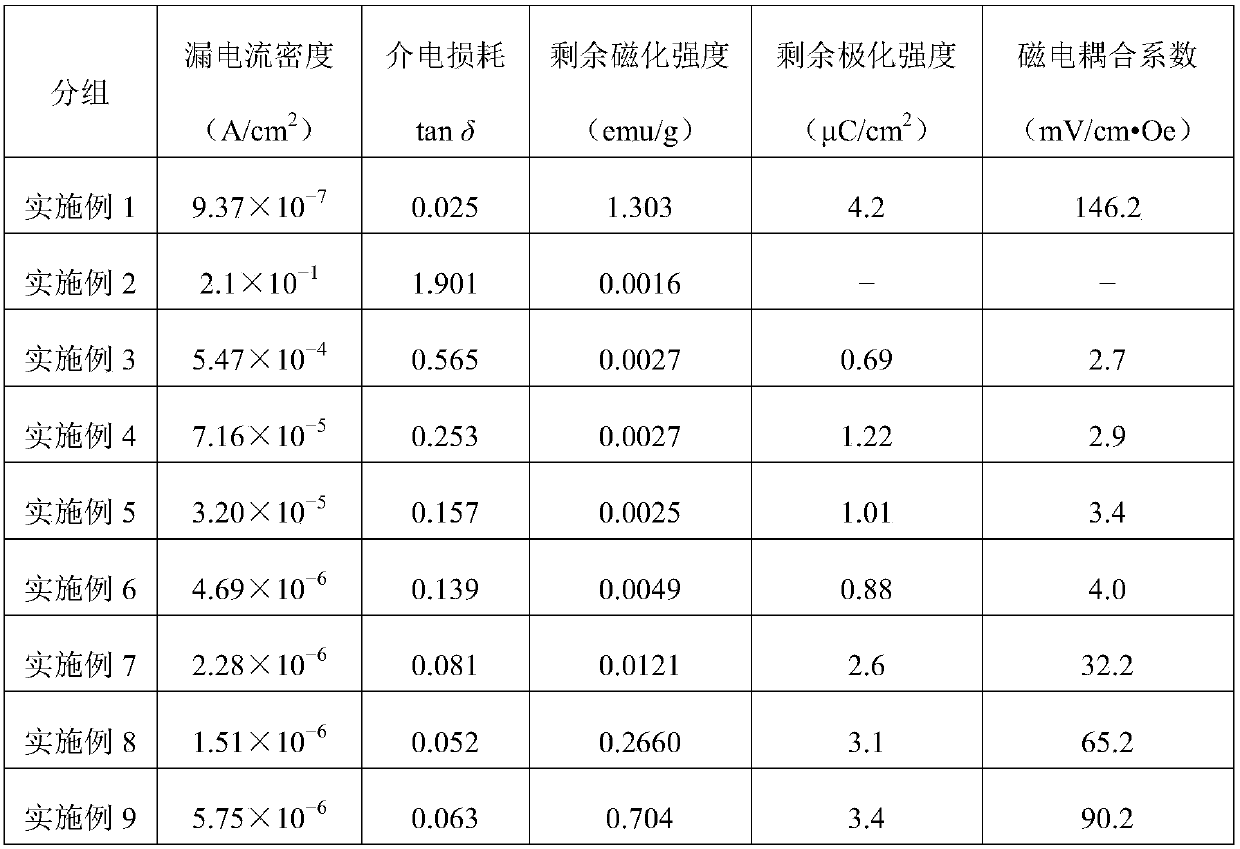

Embodiment 1

[0026] A multiferroic solid solution ceramic, the chemical composition of the multiferroic solid solution ceramic is expressed as (1-x-y)BiFeO 3 -xLaFeO 3 -yPbFeO 2.5 , where x is LaFeO 3 Mole percent of , y is PbFeO 2.5 The mole percentage of x=0.10, y=0.30, the preparation method of this multiferroic solid solution ceramics is as follows:

[0027] Step 1, prepare analytically pure powder raw material Bi 2 o 3 (purity ≥ 99.0%), Fe 2 o 3 (purity≥99.0%), La 2 o 3 (purity ≥ 99%), PbO (purity ≥ 99%), each powder raw material is dried at 500 ° C to remove moisture;

[0028] Step 2, according to the chemical formula BiFeO 3 Weigh the corresponding proportion of Bi 2 o 3 and Fe 2 o 3 , add a certain proportion of absolute ethanol for ball milling and mixing for 6 hours, take out the mixed slurry and bake in an oven at 90°C for 6 hours, pass through an 80-mesh sieve, and put the sieved mixed powder into an alumina crucible , pre-fired at 750°C for 2 hours in an air atm...

Embodiment 2

[0036] A multiferroic solid solution ceramic, the chemical composition of the multiferroic solid solution ceramic is expressed as (1-x-y)BiFeO 3 -xLaFeO 3 -yPbFeO 2.5 , where x is LaFeO 3 Mole percent of , y is PbFeO 2.5 The mole percentage of x=0, y=0.

[0037] Steps 1-2 in the preparation method of the multiferroic solid solution ceramics in this embodiment are basically the same as Steps 1-2 in Example 1, and the main difference from Example 1 lies in the subsequent steps, and the solid solution content is different at the same time, specifically x=0, y=0, due to LaFeO 3 and PbFeO 2.5 The content of is 0, therefore, does not need step 3 and step 4 among the embodiment 1, directly carries out step 5;

[0038] Step 5, weigh the above BiFeO 3 For powder, add a certain amount of deionized water for ball milling and mixing for 6 hours, take out the mixed slurry and bake it in an oven at 120°C for 12 hours, pass through a 80-mesh sieve, and add a concentration of 5wt% pol...

Embodiment 3

[0040] A multiferroic solid solution ceramic, the chemical composition of the multiferroic solid solution ceramic is expressed as (1-x-y)BiFeO 3 -xLaFeO 3 -yPbFeO 2.5 , where x is LaFeO 3 Mole percent of , y is PbFeO 2.5 The molar percentage of x=0.1, y=0.

[0041] Steps 1-3 in the preparation method of multiferroic solid solution ceramics in this embodiment are basically the same as steps 1-3 in Example 1, the main difference from Example 1 lies in the subsequent steps, and at the same time, the solid solution content is different, specifically x=0.1, y=0, due to PbFeO 2.5 The content of is 0, therefore, does not need step 4 among the embodiment 1, directly carries out step 5;

[0042] Step 5, by stoichiometric ratio 0.90BiFeO 3 -0.10LaFeO 3 Weigh the above BiFeO 3 、LaFeO 3 For powder, add a certain proportion of deionized water for ball milling and mixing for 6 hours, take out the mixed slurry and bake it in an oven at 120°C for 12 hours, pass through a 80-mesh siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Leakage current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com