Electroplating pre-treatment technology of cyanide-containing wastewater

A pretreatment and cyanide technology, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high equipment construction investment and operation investment, low efficiency of wastewater treatment, and different types of pollutants. Achieve the effects of reducing concentration, reducing reaction waiting time, reducing equipment costs and operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

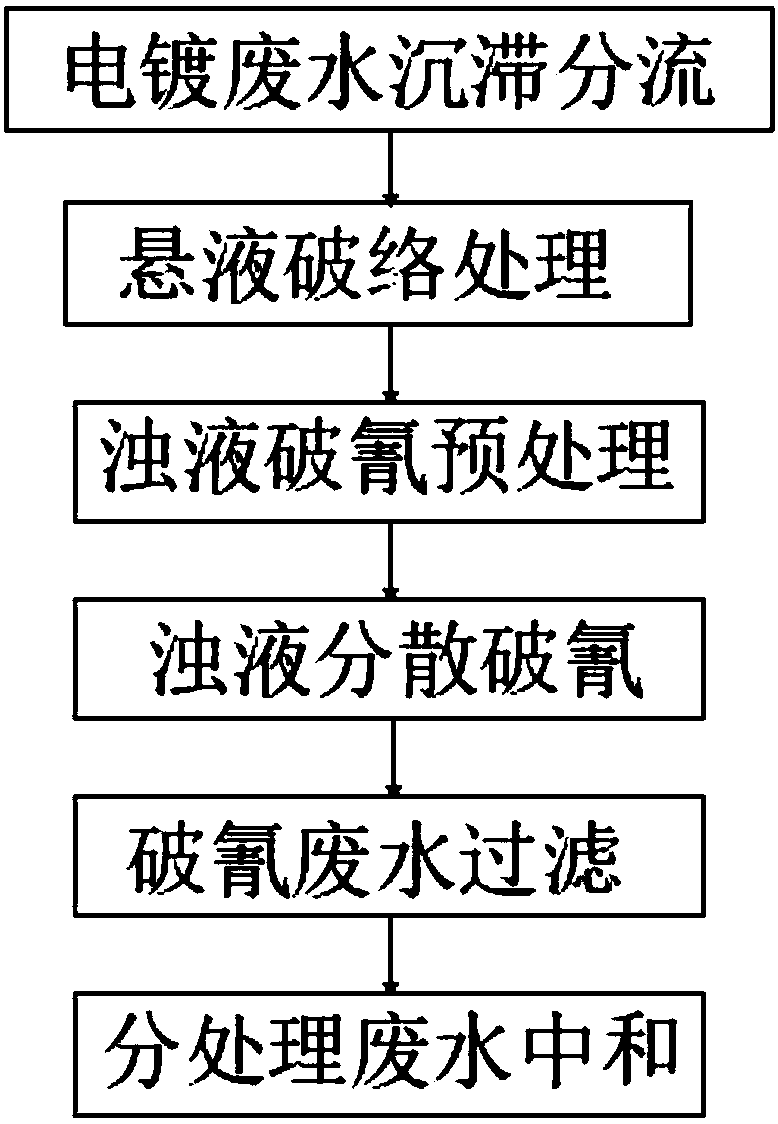

[0041] see figure 1 , a kind of cyanide-containing wastewater electroplating pretreatment process, comprises the following steps:

[0042] Step 1: The electroplating wastewater is stagnant and diverted, and the electroplating wastewater is discharged into the primary sedimentation tank for stagnant diversion. One end of the sedimentation tank is connected to the wastewater drainage equipment, and the other end is connected to the suspension diversion pipe and the turbid liquid diversion pipe. Step 1 The electroplating wastewater is stagnant and diverted During the process, the suspension diversion pipe and the turbid liquid diversion pipe connected to one end of the sedimentation tank are arranged up and down, which facilitates the separate treatment of electroplating wastewater, increases the neutralization reaction efficiency, and reduces the reaction time;

[0043] Step 2: Suspension broken network treatment, part of the electroplating wastewater that has undergone primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com