A kind of method of low temperature liquid phase synthesis stannous sulfide

A stannous sulfide, low-temperature liquid phase technology, used in chemical instruments and methods, tin compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Experimental preparation of SnS nanocrystals

[0038] The main reagents used in the experimental preparation of SnS nanocrystals are shown in Table 1. The various experimental instruments required for the experiment are listed in Table 2.

[0039] Table 1 The main reagents used in the experiment

[0040]

[0041] Table 2 main experimental equipment

[0042] serial number equipment name Specifications 1 Electronic balance TLE104E 2 Reactor 50ml 3 vacuum oven DZF-6050 4 centrifuge C14D 5 CNC ultrasonic cleaner KQ-500DE

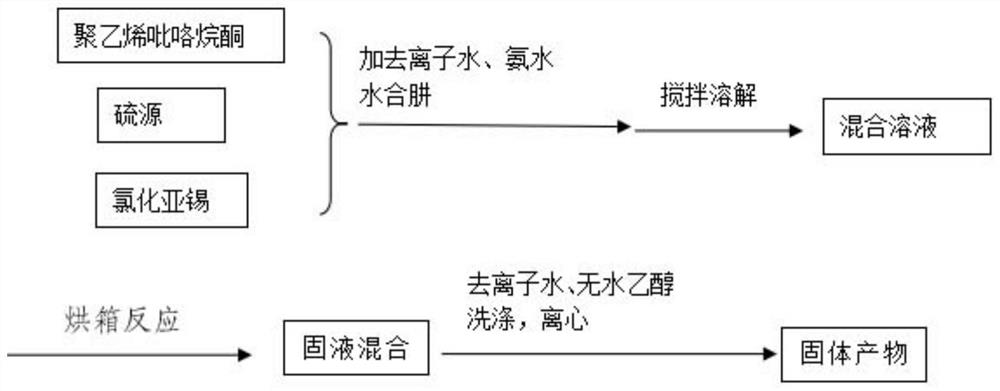

[0043] The preparation process is as figure 1 As shown, PVP is polyvinylpyrrolidone. The preparation process includes the following steps:

[0044] S1: Weigh a certain amount of PVP, add a small amount of deionized water, and stir to dissolve it. PVP with molecular weights of 5.8w and 130w were used, respectively.

[0045] S2: Weigh quantitative sulfur source, SnCl 2 (anhydr...

Embodiment 2

[0058] Example 2: Scanning electron microscope (SEM) analysis results of SnS

[0059] Figure 4 What is shown is the SEM picture of SnS prepared by the inventive scheme, and it can be seen that it is a very regular and regular crystal structure, indicating that the method can prepare the target product.

[0060] Discussed the preliminary products that different reaction conditions obtain in embodiment 1, the SEM image that these products are carried out scanning electron microscope to obtain is as follows Figure 5 shown. Figure A shows the product with a holding time of 6 hours. It can be seen from the picture that it contains many impurities, and the shape is different and relatively complicated. Although a little target product can be barely seen, the result is not ideal, so the holding time of 6 hours The reaction conditions were not suitable. Figures B and C are the products obtained by incubating at 80°C and 65°C for 24 hours respectively. The product obviously has a ...

Embodiment 3

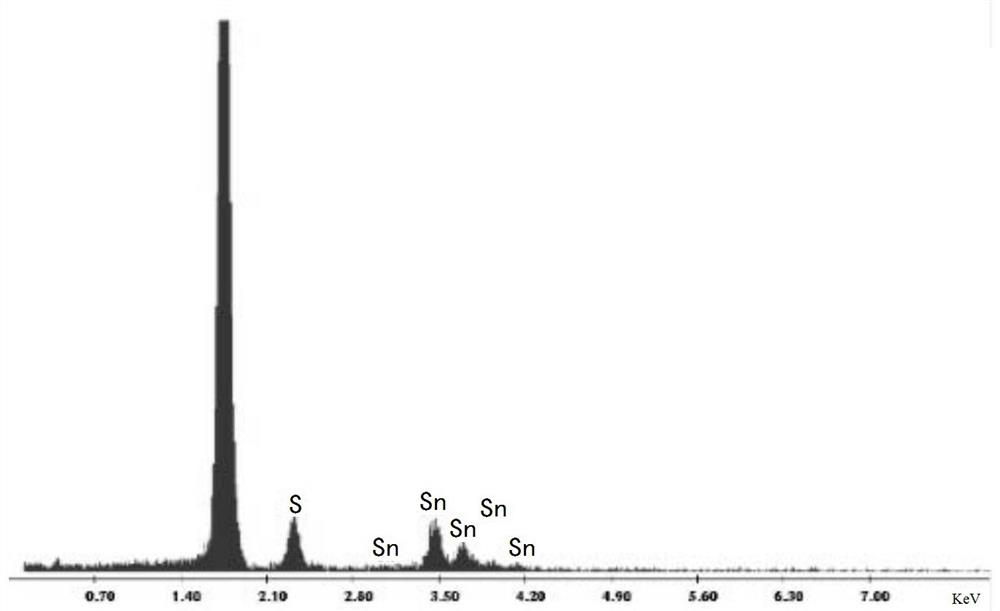

[0061] Embodiment 3: X-ray energy spectrum (EDS) analysis of SnS

[0062] Figure 6 It is an EDS spectrum obtained by attaching the product prepared by the method of the present invention to the surface of single crystal silicon in Example 1, and then performing X-ray energy spectrum analysis. There is an S peak at the position of 2.3KeV, and there are two more obvious Sn peaks at 3.5KeV and 3.7KeV respectively. Looking at the individual peaks, it can be seen that the two peaks of Sn are slightly lower than the S peak, but higher than the background. It shows that this product is indeed composed of S and Sn elements. From the quantitative analysis results, it can be seen that the peak area ratio of S and Sn is 1:1. It can be concluded that the product made is SnS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com