Coating machine rolling mechanism

A technology of winding mechanism and coating machine, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of insufficient deviation correction ability, etc., and achieve convenient disassembly, loading and unloading, strong deviation correction ability and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

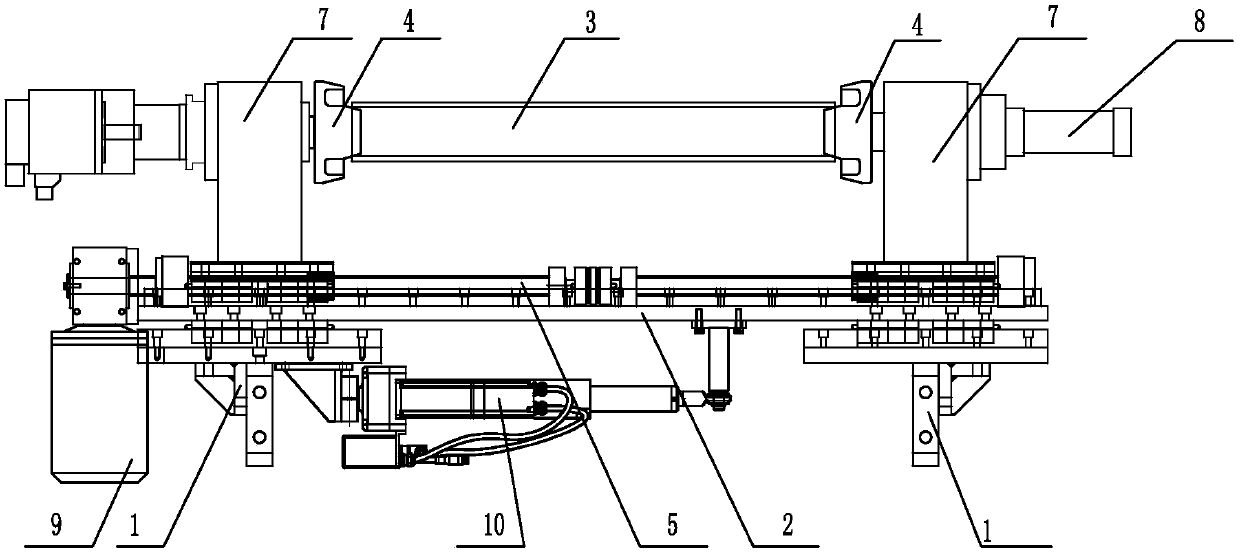

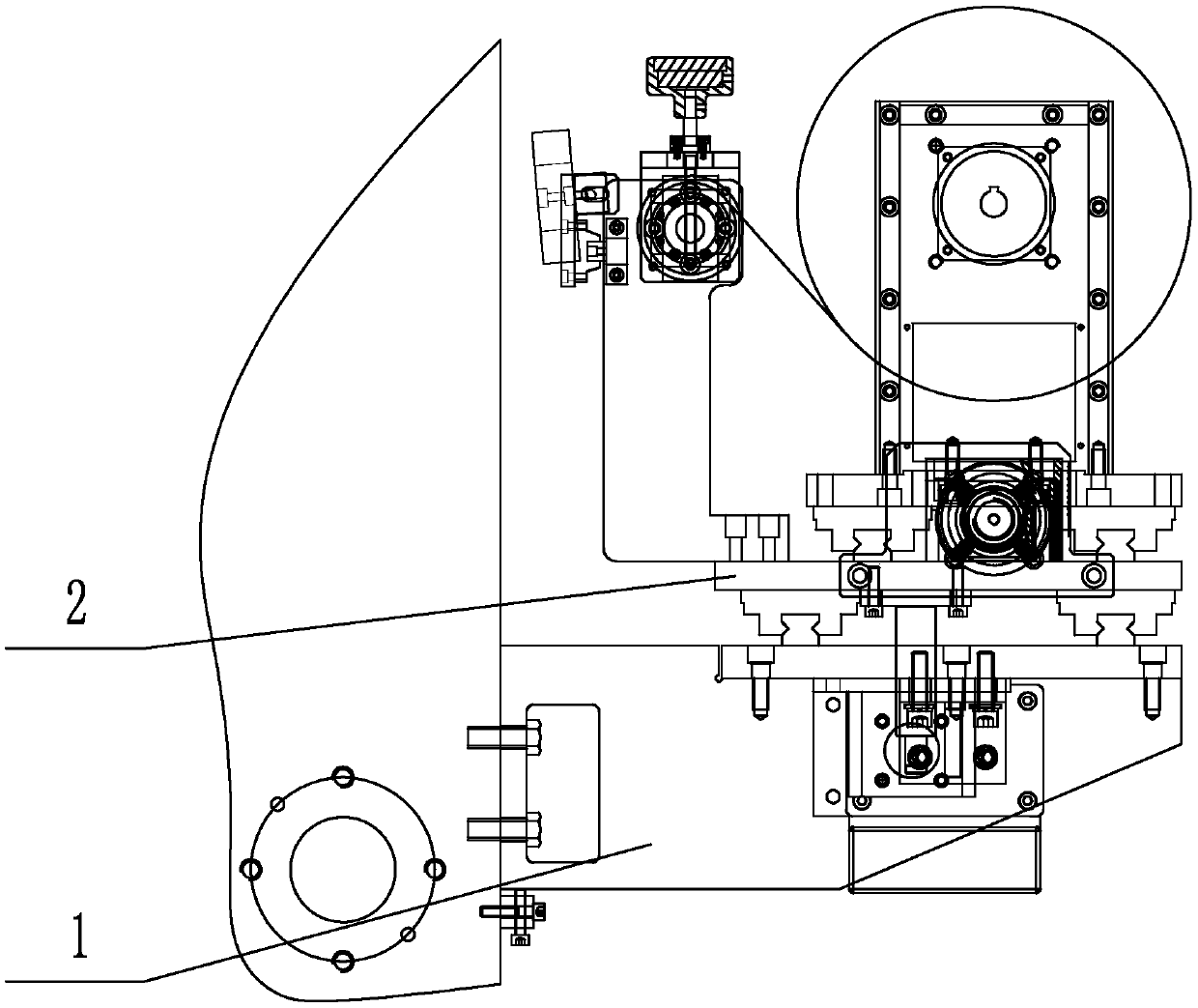

[0018] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a coating machine winding mechanism includes: a main frame; a support platform 1 arranged on the main frame; The sliding platform 2 on the top; the clamping mechanism arranged on the sliding platform 2 is used to clamp the winding core 3; the deviation correction system 10 can drive the sliding platform 2 to slide horizontally on the support platform 1. Through the above structure, the deviation correction system 10 can drive the sliding platform 2 to move, and then drive the winding core 3 clamped by the clamping mechanism arranged on the sliding platform 2 to shift, so as to realize the deviation correction function, and Since the support platform 1 can be drawn out at any position, the two ends of the sliding direction of the sliding platform 2 on the support platform 1 are not provided with traction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com