Blade propeller for cargo ship

A technology for propellers and cargo ships, which is applied in the direction of rotating propellers, ship propulsion, ship parts, etc., can solve the problems of adverse effects of ship navigation development, large energy loss, low work efficiency, etc., to weaken the radial migration effect, improve power, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

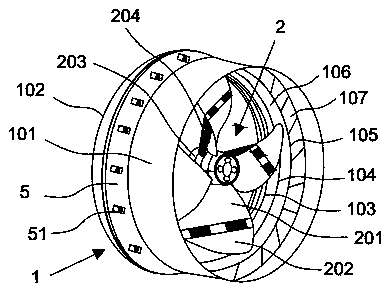

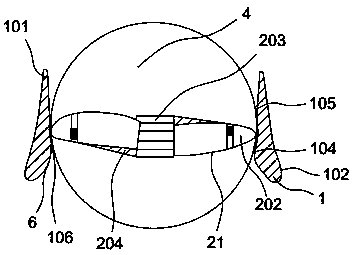

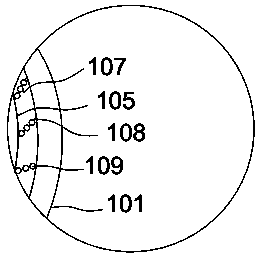

[0029] like Figure 1-7 As shown, the solution adopted by the present invention to achieve the above object is: a split-bladed propeller for cargo ships, comprising a draft tube 1 and a propeller 2 with at least one blade 21, the blade 21 comprising a flap in the front end region 202, the propeller 2 is arranged in the draft tube 1 in the following manner: a turbulence groove 106 along the circumferential direction of the draft tube 1 is formed between the flap 202 in the front end region of the blade 21 and the inner wall 6 of the draft tube 1 , the water inlet end of the diversion pipe 1 is provided with a protective cover 7, and one end surface of the protective cover 7 is evenly distributed with a retaining bar 73 ring cloth connected to the surface of the ring 74, the ring 74 is provided with a rotating ball 75, and the protective cover 7 is provided with Evenly distributed on the blade 76 on the ball 75, the ball 75 can rotate in the ring 74. By arranging the propeller ...

Embodiment 2

[0042] The working principle of a split-bladed propeller for a cargo ship in the present invention is as follows: the propeller 2 is installed in the guide tube 1, so that the flap 202 in the front end region of the blade 21 and the inner wall 6 of the guide tube 1 form a The turbulence groove 106 in the circumferential direction of the flow pipe 1 is adjusted to expand and contract the telescopic push rod 204, so that the paddle 21 is turned to a suitable angle, and the propeller 2 is started to rotate. The formed rotating water flow drives the auxiliary paddle 3 to rotate, which improves the overall power.

Embodiment 3

[0044] Comparative Test

[0045] Get respectively a kind of cargo ship of the present invention with split-blade propeller and the common ship propeller on the market to compare, and at the same time, in the same sea area, drop a kind of cargo ship with split-blade propeller of the present invention and ship with paddle on the market to test respectively, During this process, power, open water efficiency, and stability are monitored.

[0046]

[0047] Result: Through the above experiments, it can be concluded that a kind of split-blade propeller for cargo ships of the present invention is better than ordinary ship propellers on the market. During use, the split-blade propeller for cargo ships of the present invention has better power, open water efficiency, stability The performance is better than that of ordinary ship oars on the market, so this device can better provide power for ships.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com