Mop with inverted scraper

An inverted scraper and mop technology, applied in the field of mops, can solve the problems of inconvenient use and frequent cleaning, and achieve the effects of convenient use, improved mopping efficiency, and reduced cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

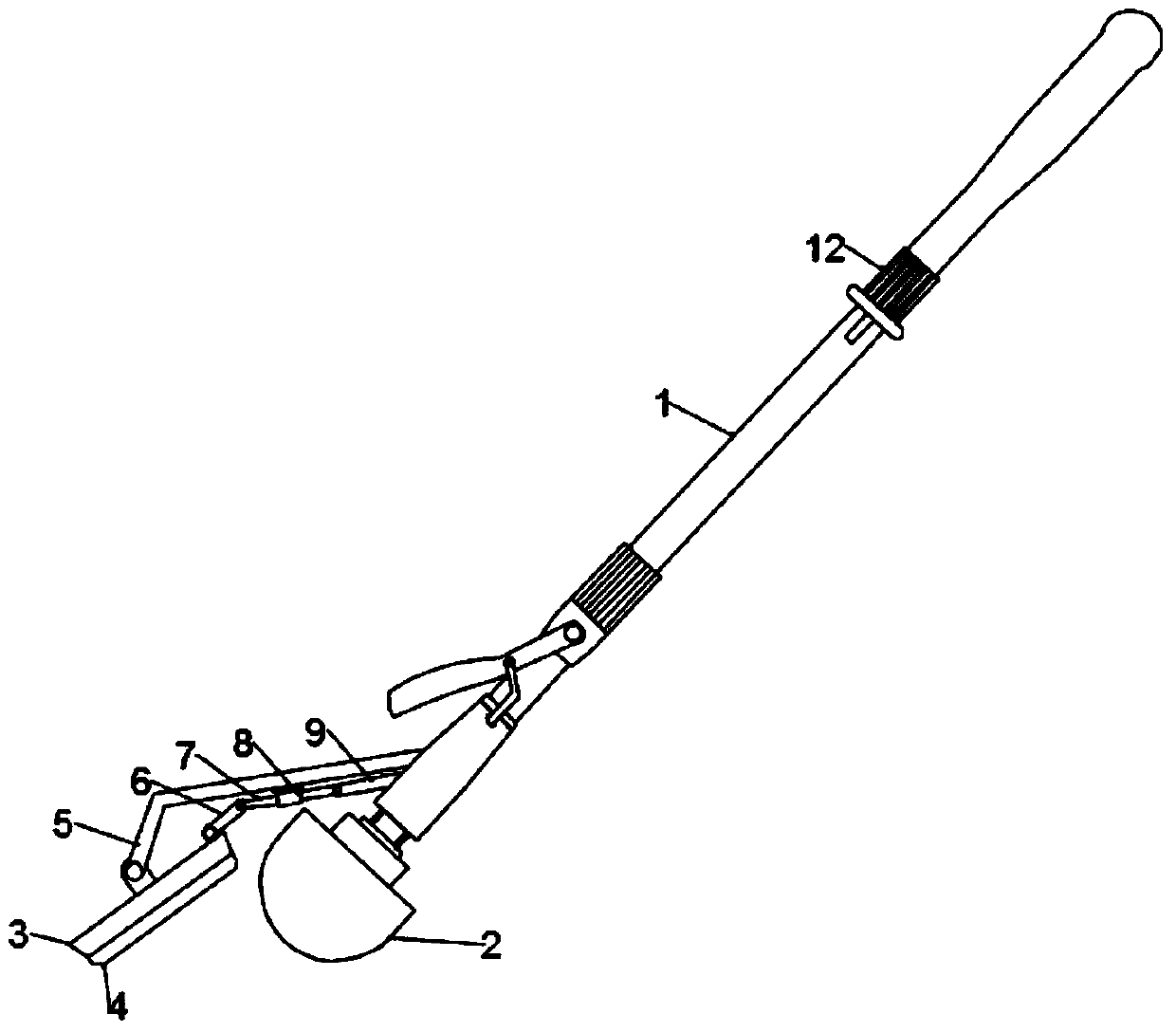

[0023] see Figure 1~3 , in an embodiment of the present invention, a mop with an inverted scraper includes a mop body; the mop body includes a handle 1 for holding and a mop head 2 for mopping the floor, and the mop body is provided with The upper end of the duct plate 3 is hinged to the fixed rod 5 through the inverted scraper 3 connected with the fixed rod 5 , and an adjustment mechanism is installed on the right side of the inverted scraper 3 .

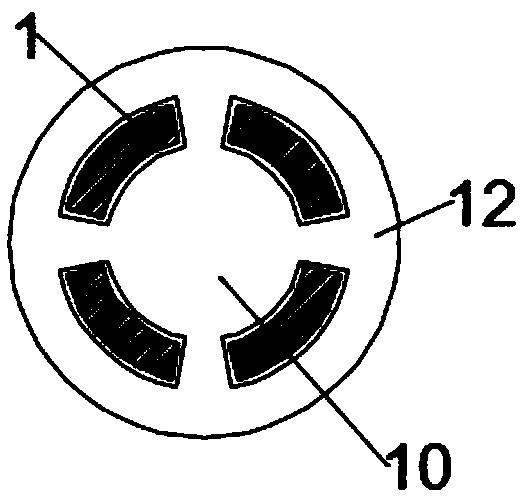

[0024] The adjusting mechanism includes a first connecting rod 6, a movable rod 7, a second connecting rod 9 and a push rod 10. The movable rod 7 runs through the collar 8 fixed on the lower end of the fixed rod 5 and is slidably connected with the inner wall of the collar 8, and moves One end of the rod 7 is connected with one end of the first connecting rod 6, the other end of the first connecting rod 6 is connected with the inverted scraper 3, the other end of the movable rod 7 is connected with one end of the second connecting...

Embodiment 2

[0030] see Figure 4 The difference between the second embodiment and the first embodiment is that the lower end of the inverted scraper 3 is symmetrically equipped with pulleys, and an endless belt 13 is rotatably connected to the pulleys, and an adjusting handle 14 is fixedly installed on the rotating shaft of one of the pulleys. The adjustment handle 14 is handed over with an L-shaped rod, which is inserted into the clamping hole provided on the inverted scraper 3. When the L-shaped rod breaks away from the clamping hole, the adjustment of the endless belt 13 can be realized. The outside of the endless belt 13 A sponge is installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com