Ultrahigh altitude copper-gold mine wasteland greening method

A wasteland and altitude technology, applied in land preparation methods, botanical equipment and methods, excavation, etc., can solve the problems of lack of vegetation restoration methods in mine wasteland, large evaporation in ultra-high altitude areas, and large temperature difference between day and night, and achieve good results. The effect of isolation and water retention, strong resistance to rain erosion, and small permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

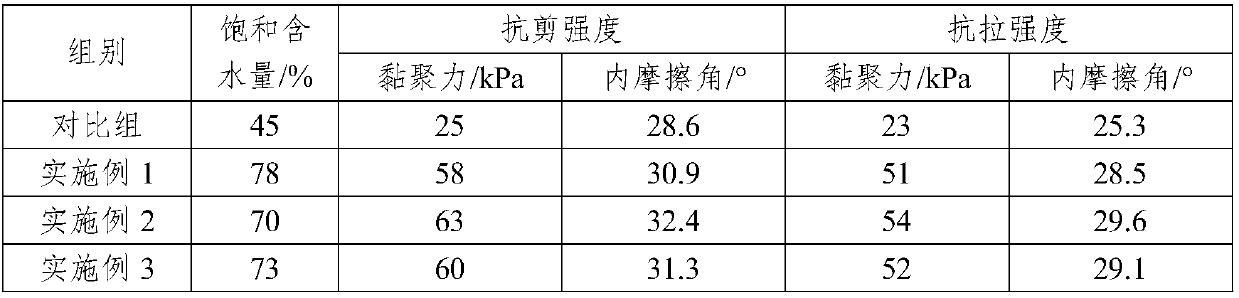

Examples

Embodiment 1

[0056] A method for regreening the abandoned land of an ultra-high altitude copper-gold mine, the steps are as follows:

[0057] (1) Slope finishing

[0058] Mountains with a slope greater than 70 degrees should be slope-cut;

[0059] (2) Interception and drainage works

[0060] Set intercepting ditches at the top of the slope, vertical drainage ditch on the slope surface, and drainage ditch at the bottom of the slope;

[0061] (3) hanging protective net

[0062] A protective net is laid on a site with a slope greater than 30°, the protective net includes an upper metal protective net and a lower flexible protective net, the metal protective net is anchored with a metal anchor, and the flexible protective net is fixed with a steel wire anchor; The metal mesh is a hot-dip galvanized wire mesh with an aperture of 20*20cm, the flexible protective mesh is a steel wire rope mesh with an aperture of 2*2m, and the metal anchor is a steel anchor.

[0063] (4) Artificial soil matri...

Embodiment 2

[0071] The volume ratio of the middle and lower layers, middle and upper layers, and surface layer components of the soil matrix of this embodiment is different from that of Embodiment 1, and other steps are all the same as that of Embodiment 1.

[0072] In the soil matrix of this embodiment, the middle and lower layer matrix includes the following components and component volume ratios: 45% of loam soil, 35% of decomposed highland barley straw, 14.05% of crushed highland barley straw, 0.15% of compound microbial preparation, 5.6% of biochar, 0.2% polyglutamic acid; the upper and middle matrix includes the following components and component volume ratios: 45% loam soil, 35% decomposed highland barley straw, 13.65% crushed highland barley straw, 0.15% compound microbial preparation, 5.6% biochar, poly 0.2% of glutamic acid, 0.4% of seeds; the surface matrix includes the following components and component volume ratios: 23% of loam, 75% of highland barley straw crushed and passed...

Embodiment 3

[0074] The volume ratio of the middle and lower layers, middle and upper layers, and surface layer components of the soil matrix of this embodiment is different from that of Embodiment 1, and other steps are all the same as that of Embodiment 1.

[0075] In this embodiment, the middle and lower layer matrix includes the following components and component volume ratios: 40% loam, 40% decomposed highland barley straw, 11.4% crushed highland barley straw, 0.3% compound microbial preparation, 8% biochar, polyglutamine acid 0.3%; the upper and middle layers of the matrix include the following components and component volume ratios: 40% loam, 40% decomposed highland barley stalks, 11% crushed highland barley stalks, 0.3% compound microbial preparations, 8% biochar, polyglutamic acid 0.3%, seeds 0.4%; the surface matrix includes the following components and component volume ratios: 18% of loam, 80% of highland barley straw crushed and passed through a 4-mesh sieve, and 2% of soil bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com