Terahertz quasi-elliptical waveguide filter that is easy to implement by CNC

An elliptical waveguide and filter technology, which is applied in the field of waveguide filters in the terahertz band, can solve problems such as poor out-of-band rejection, limited precision, and application restrictions, and achieve alignment problems, low loss performance, and good edge selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

[0034] The filter described in this application adopts the current CNC process to process the WR-4 frequency band filter, so that the filter works in the 220GHz frequency band, has a low insertion loss characteristic of -0.6dB, and there are two obvious two close The zero point of the passband makes the edge selection characteristics of the filter very good, that is, a quasi-elliptic response is realized. Applied to the terahertz detection system, it can realize the continuum astronomical observation of 10% bandwidth in the 220GHz frequency band.

[0035] The specific structure is as follows:

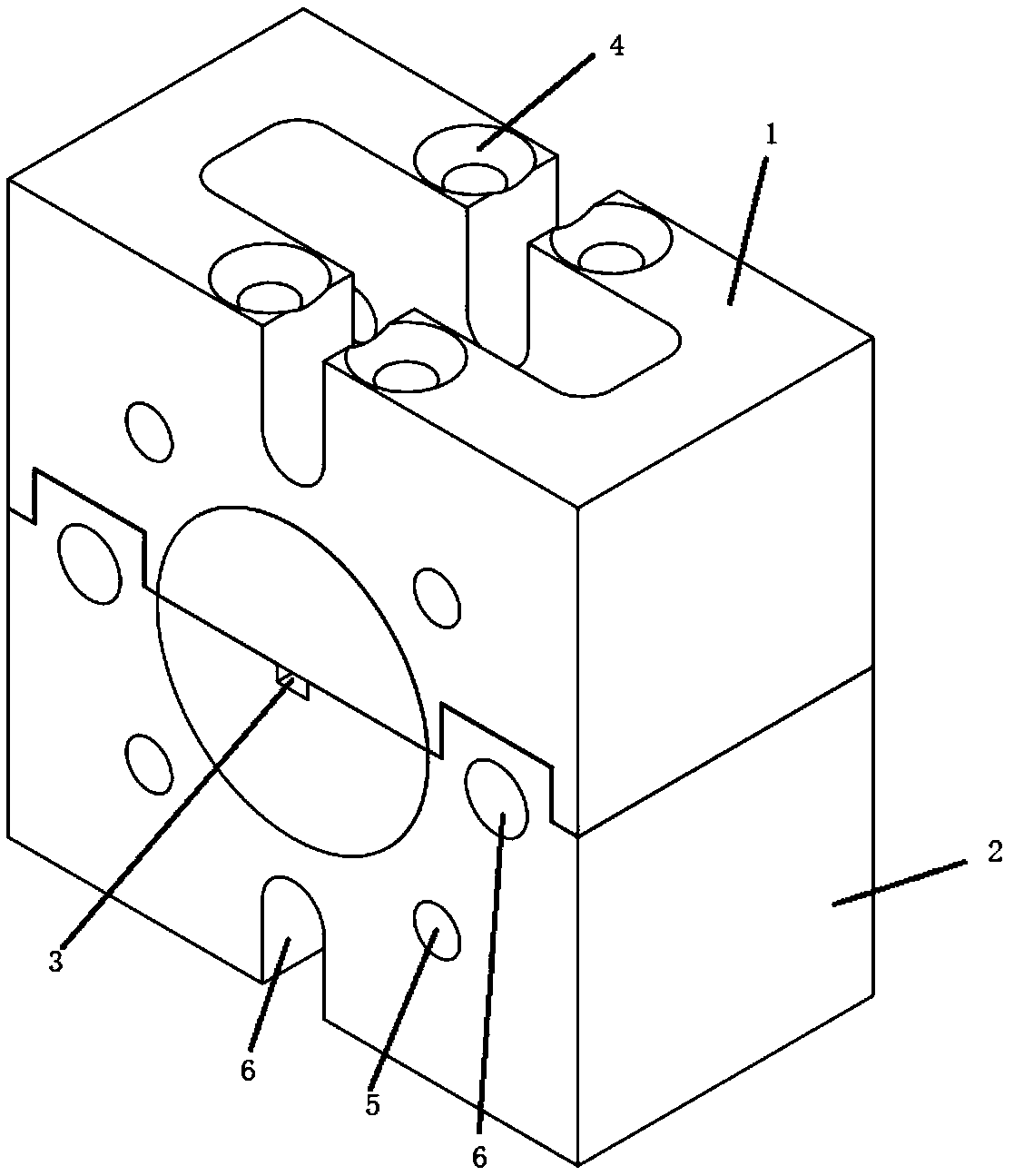

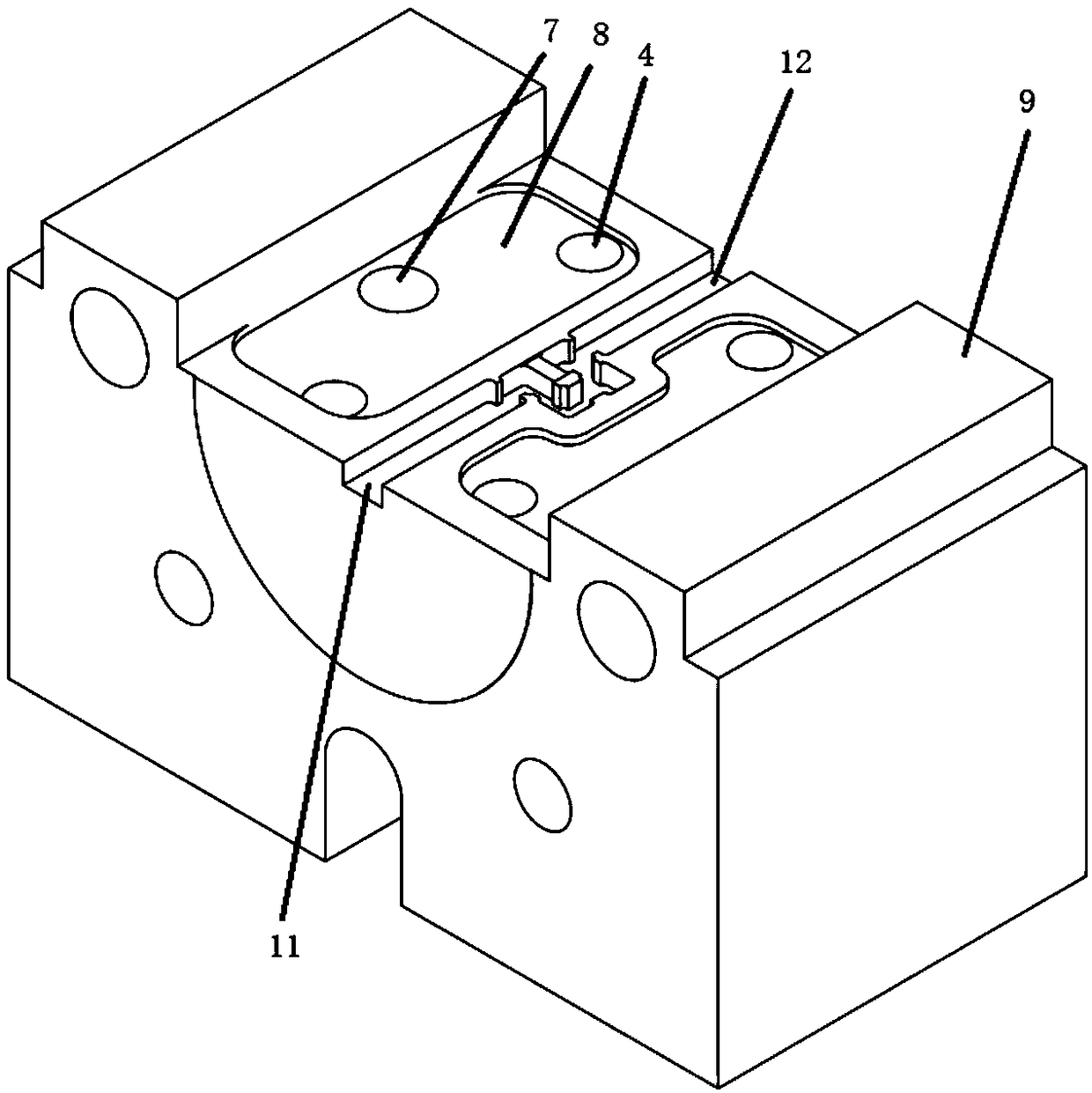

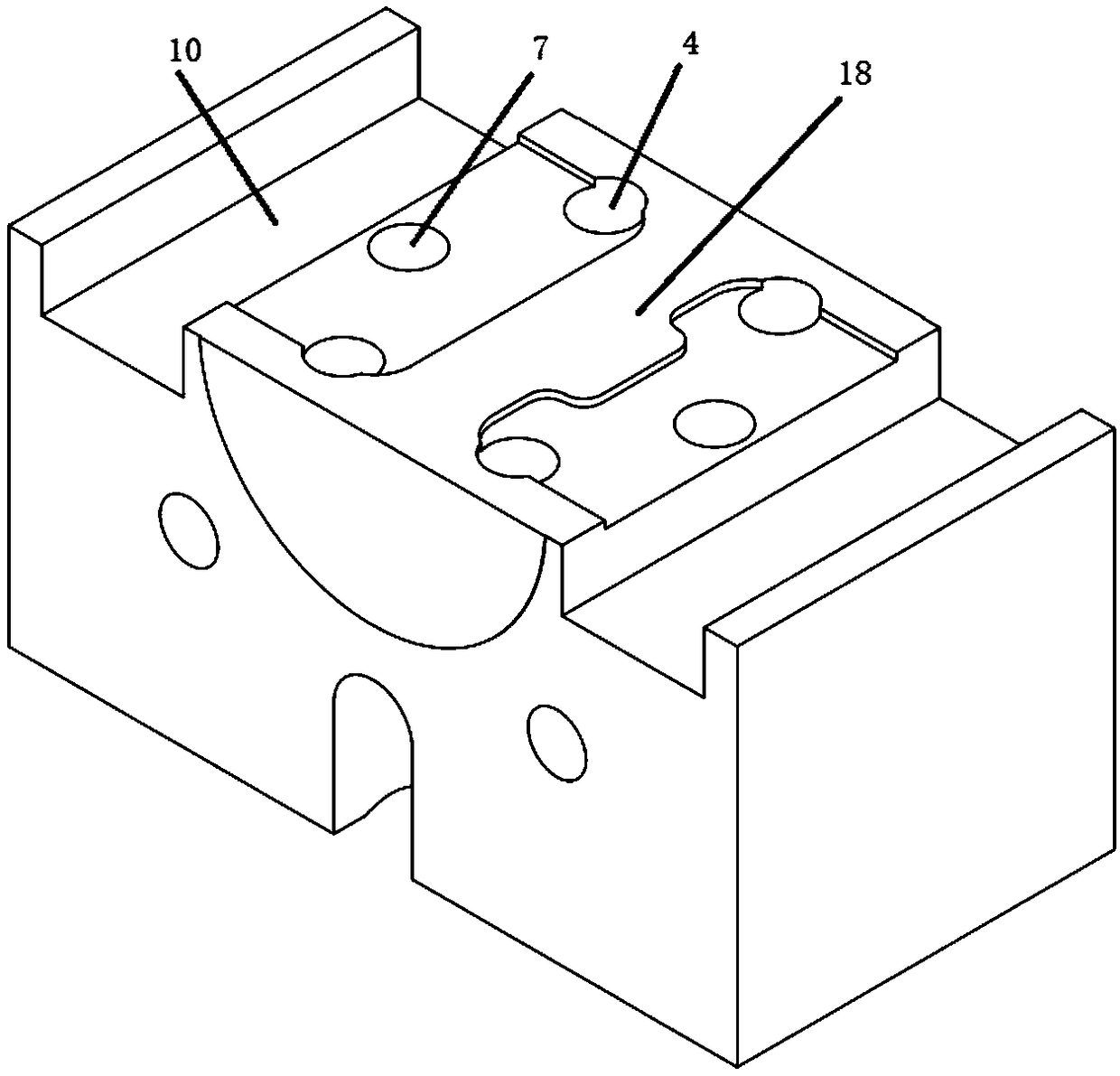

[0036] Such as Figure 1 to Figure 4As shown, a terahertz quasi-elliptic waveguide filter that is easy to realize by CNC is characterized in that: it includes an upper structural block 1 and a lower structural block 2, and the upper structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com