A self-cleaning flexible conductive circuit and its preparation method

A flexible conductive and self-cleaning technology, applied in the field of flexible microelectronics, can solve the problems of low bonding strength, poor line edge selectivity, poor reliability of conductive lines, etc., and achieve the effects of simple method, improved bonding strength, and good reliability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

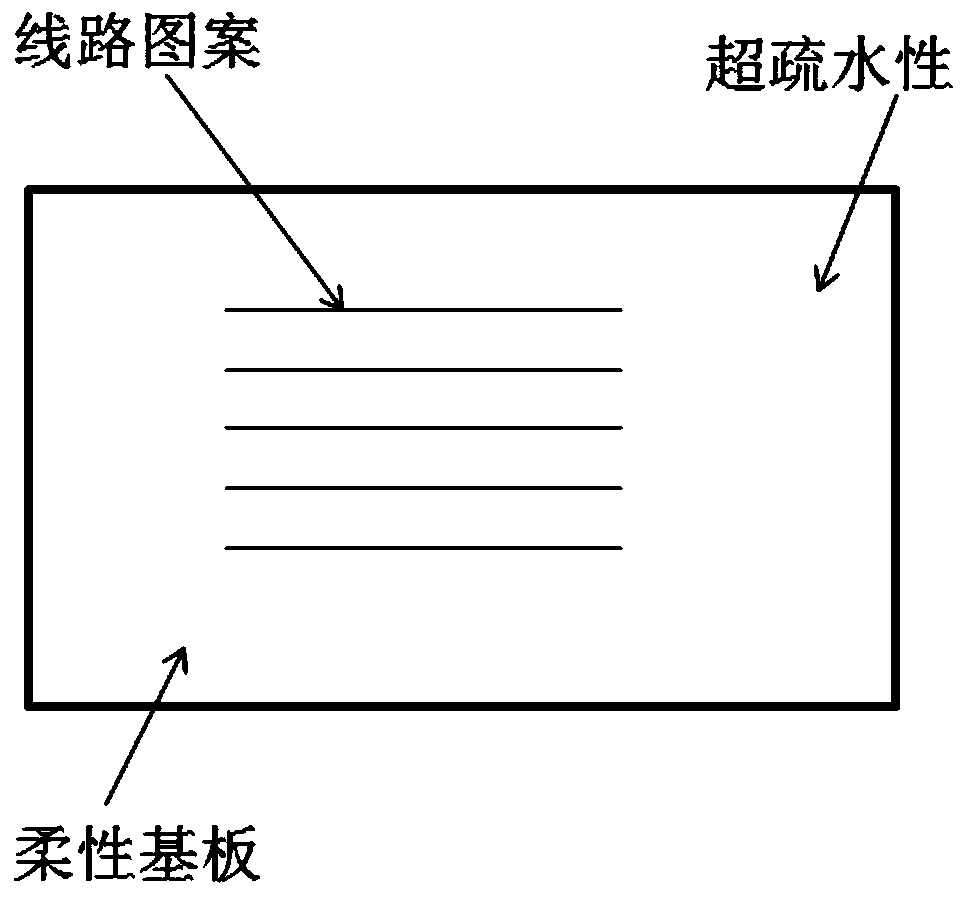

[0030] Such as figure 1 Shown, a kind of preparation method of self-cleaning flexible conductive circuit comprises:

[0031] (1) Use a nanosecond pulse laser with a wavelength of 256nm-1064nm and a single pulse energy of 0.1μJ-20μJ to etch and scan the cleaned flexible substrate. When the content of hydrophilic groups on the surface of the flexible substrate is reduced and a micro-protrusion structure is formed, According to the Cassie and Baxter wetting model, the surface of the flexible substrate exhibits superhydrophobicity;

[0032] (2) Using the ultraviolet pulse laser with a single pulse energy of 1μJ-50μJ to etch the circuit pattern on the superhydrophobic flexible substrate, the content of hydrophilic groups on the surface of the area after the laser secondary action increases and forms a groove structure, According to the Wenzel wetting model, the circuit pattern is superhydrophilic;

[0033] (3) Coat the surface of the flexible substrate after the laser treatment i...

Embodiment 1

[0037] A nanosecond pulse laser with a wavelength of 355 nm and a single pulse energy of 0.1 μJ was used to etch and scan the cleaned polyimide flexible substrate, so that the surface of the substrate appeared superhydrophobic. The ultra-hydrophilic circuit pattern was etched on the super-hydrophobic substrate by using an ultraviolet pulse laser with a single pulse energy of 1 μJ again. A solution containing silver ammonia ions at a concentration of 0.1 mol / L was coated on the surface of the substrate after laser treatment, and after 5 minutes, the substrate was cleaned with deionized water and dried. Finally, put the base material adsorbed with silver ammonia ions into the chemical gold plating solution, the chemical gold plating solution is a common commercial plating solution, the temperature is controlled at 50° C., and the gold plating time is 50 minutes. After completion, take it out, wash it, and dry it to obtain a self-cleaning flexible conductive circuit.

Embodiment 2

[0039]A nanosecond pulse laser with a wavelength of 1064 nm and a single pulse energy of 0.5 μJ was used to etch and scan the clean polyethylene terephthalate flexible substrate, making the surface of the substrate superhydrophobic. The ultra-hydrophilic circuit pattern was etched on the super-hydrophobic substrate by using an ultraviolet pulse laser with a single pulse energy of 2 μJ again. A solution containing silver ions at a concentration of 0.5 mol / L was coated on the surface of the substrate after laser treatment, and after 10 minutes, the substrate was cleaned with deionized water and dried. Finally, the substrate with the silver ions adsorbed is put into the electroless copper plating solution, which is a common commercial plating solution, the temperature is controlled at 50° C., and the copper plating time is 50 minutes. After completion, take it out, wash it, and dry it to obtain a self-cleaning flexible conductive circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com