Semiconductor production line dynamic load balanced feeding control method

A dynamic load and load balancing technology, applied in program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of only focusing on the workload control of bottleneck equipment, the inability of research results to be directly applied, and the inability of SA to adapt to bottleneck drift, etc. Achieve the effect of shortening the production cycle, good real-time performance, and reducing the number of products in process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

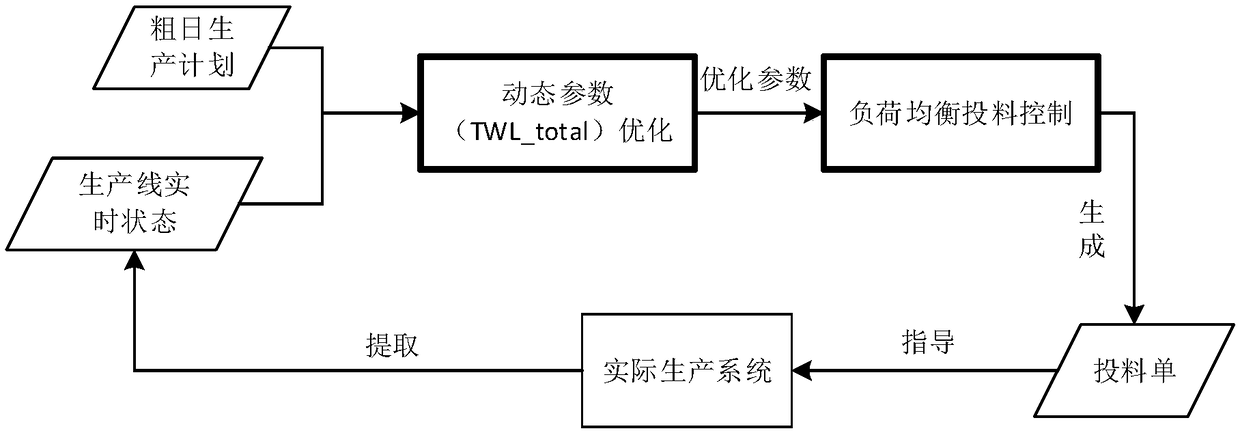

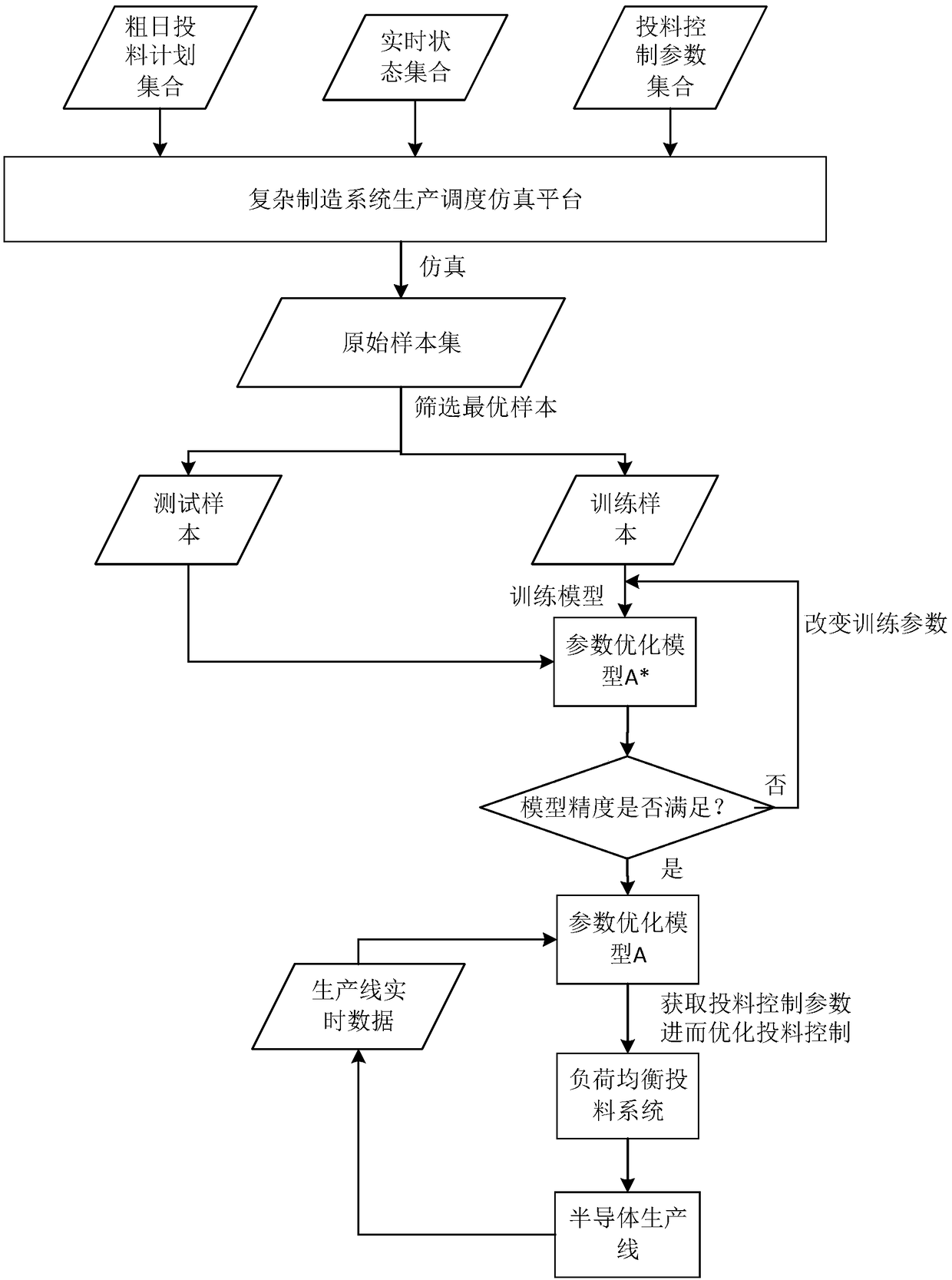

[0054] Such as figure 1 As shown, the present invention provides a kind of dynamic load balance feeding control method of semiconductor production line, the method utilizes the load balance feeding control parameter model based on ELM (Extreme Learning Machine, Extreme Learning Machine) to dynamically obtain the total load of semiconductor production line, with the total load of the semiconductor production line Guided by the load, the load control (WorkloadControl, WLC) theory is used to realize the load-balanced feeding control of the semiconductor production line, which specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com