Anti-poisoning high-adhesion organic silicon heat-conductive sealant and preparation method thereof

A sealant, anti-poisoning technology, applied in chemical instruments and methods, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the thermal conductivity of sealing silicone needs to be improved, the stability and life span are greatly affected, etc. problem, to achieve the effect of protecting platinum catalyst activity, good sealing and dustproof effect, and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

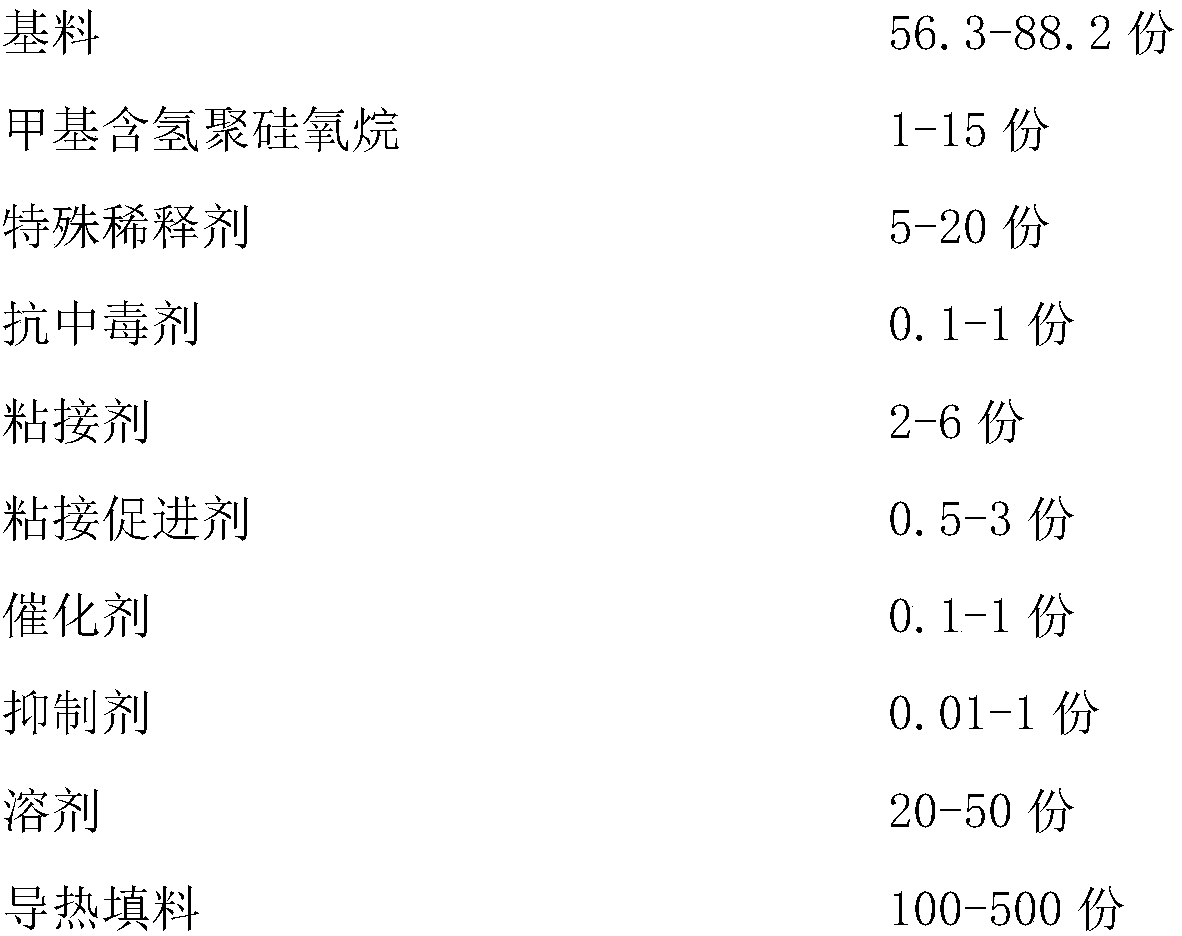

[0038] Base material preparation: at room temperature, add 75 parts of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 5 parts of structure control agent dimethyldichlorosilane (DMDC), and 20 parts of fumed silica R974 to the kneading In the machine, the rotation speed is 50rpm, mixed at 150°C for 2 hours, and vacuumized to obtain the base material;

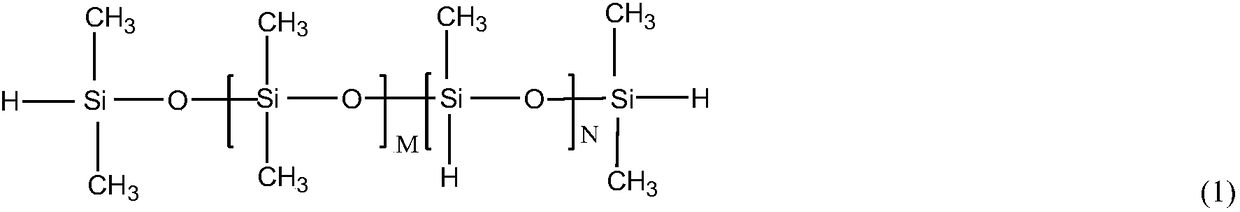

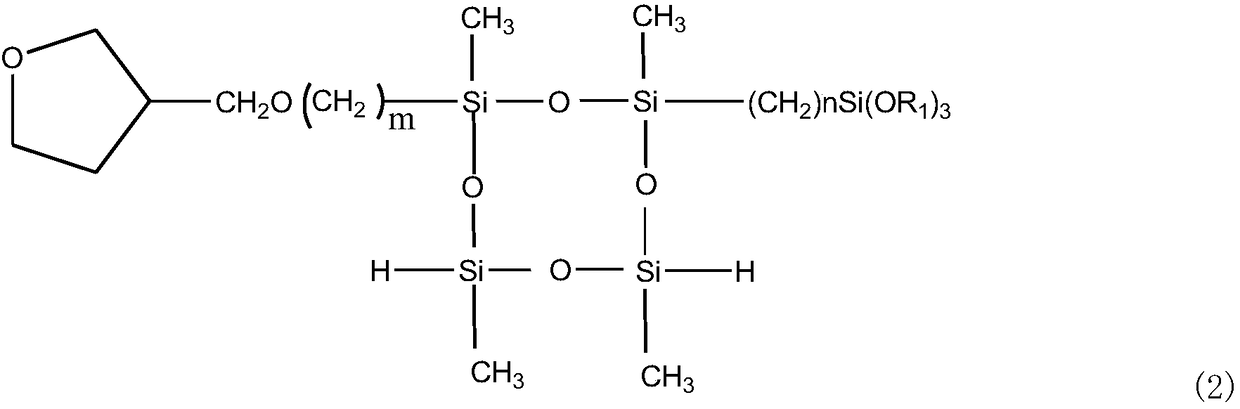

[0039] Preparation of thermally conductive sealant: at room temperature, add 72 parts of base material to a double planetary mixer, methyl hydrogen polysiloxane, such as structural formula (1), wherein M=1, N=5, 12 parts, inhibitor 2- 0.5 parts of methyl-3-butyn-2-ol, after mixing evenly, add special diluent polyvinyl silicone oil, viscosity 500mPa.s, vinyl content 0.1wt%, 10 parts, anti-poisoning agent platinum (0)- 0.5 parts of divinyltetramethyldisiloxane complex, adhesive, such as structural formula (2), wherein m=2, n=2, R 1 =-CH 3 , 4 parts, 1 part of adhesion promoter methyl borate, platinum catalyst plati...

Embodiment 2

[0041] Base material preparation: at room temperature, add 80 parts of vinyl-terminated silicone oil with a viscosity of 50000mPa.s, 4 parts of structural control agent methyltrimethoxysilane (MTMO), and 25 parts of fumed silica R972 to the In the kneader, the rotation speed is 50rpm, mixed at 150°C for 2 hours, and vacuumized to obtain the base material;

[0042] Preparation of thermally conductive sealant: at room temperature, add 65.8 parts of base material to a double planetary mixer, methyl hydrogen polysiloxane, such as structural formula (1), wherein M=2, N=1, 6.7 parts, inhibitor acetylene ring 0.2 parts of hexanol, after mixing evenly, add special diluent polyvinyl silicone oil, viscosity 2000mPa.s, vinyl content 0.055wt%, 20 parts, anti-poisoning agent platinum (0)-vinyl amino complex, 1 part , adhesive, such as structural formula (3), wherein, x=3, y=2, 5 parts, adhesion promoter ethyl borate, 1.2 parts, platinum catalyst platinum (0)-divinyltetramethyldisiloxane ...

Embodiment 3

[0044] Preparation of base material: at room temperature, 56.8 parts of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 19.2 parts of vinyl-terminated silicone oil with a viscosity of 10000mPa.s, and 4.5 parts of hexamethyldisilazane (HMDZ) as a structural control agent , Vapor-phase process silica DM-20, 30 parts, added to the kneader in turn at 50 rpm, mixed at 150°C for 2 hours, and vacuumed to obtain the base material.

[0045] Preparation of thermally conductive sealant: at room temperature, add 79.6 parts of base material to a double planetary mixer, methyl hydrogen polysiloxane, such as structural formula (1), wherein M=5, N=3, 12 parts, inhibitor 3- 0.6 parts of methyl-1-pentyn-3-ol, after mixing evenly, add special diluent polyvinyl silicone oil, viscosity 1000mPa.s, vinyl content 0.07wt%, 15 parts, anti-poisoning agent platinum (0)- Divinyltetramethyldisiloxane complex, 0.6 part, anti-poisoning agent platinum (0)-vinyl amino complex platinum (0)-vinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com