Refining method for pentoxifylline recycling products

A technique for refining pentoxifylline, which is applied in the field of refining recovered pentoxifylline products, and can solve problems such as unreachable single impurity, failure to meet finished product standards, poor impurity removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

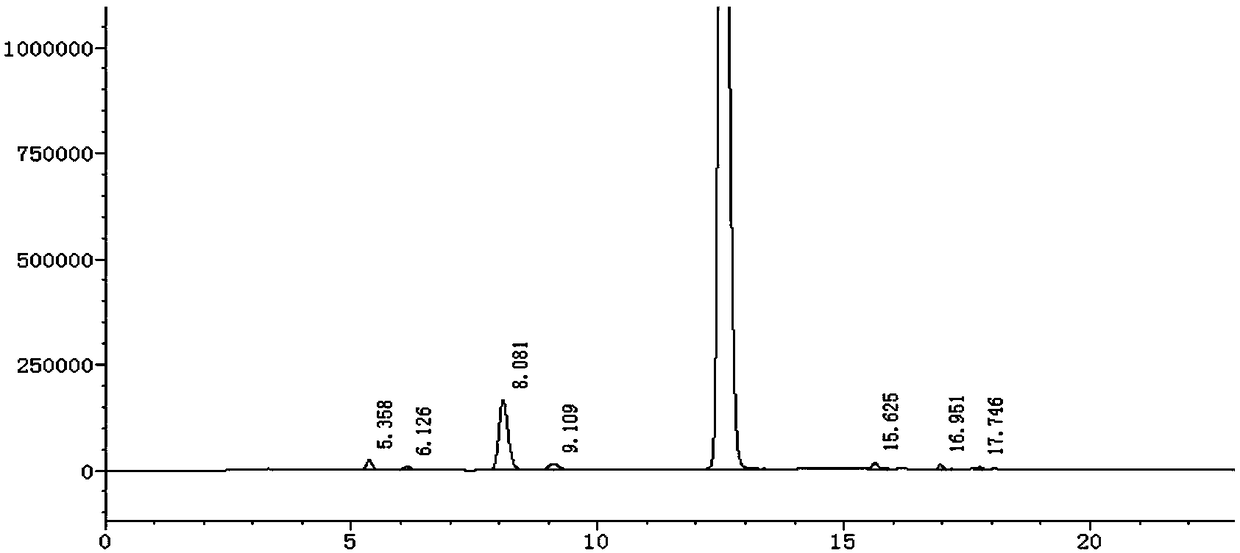

Embodiment 1

[0030] Dissolve 20 g of the recovered product of pentoxifylline (maximum single impurity 4.02%, total impurity 8.25%) in water, add 30% liquid caustic soda to adjust the pH value to 12, add reducing agent sodium triacetoxyborohydride 1.0 g, and keep warm at 80°C for 1 hour. After filtering, cool down to below 20°C to obtain an alkaline solution. This alkaline solution was mixed with chloroform, allowed to stand for layers, and the organic phase was evaporated to obtain a viscous liquid. Then add methanol to dissolve the viscous liquid, add charcoal and keep it at reflux temperature for 1 hour, remove the charcoal by hot filtration, and a large amount of pentoxifylline will be precipitated at room temperature, and the finished product will be obtained after cold filtration and drying. The yield is 81.2%, the maximum single impurity is 0.06%, and the total impurity is 0.40%.

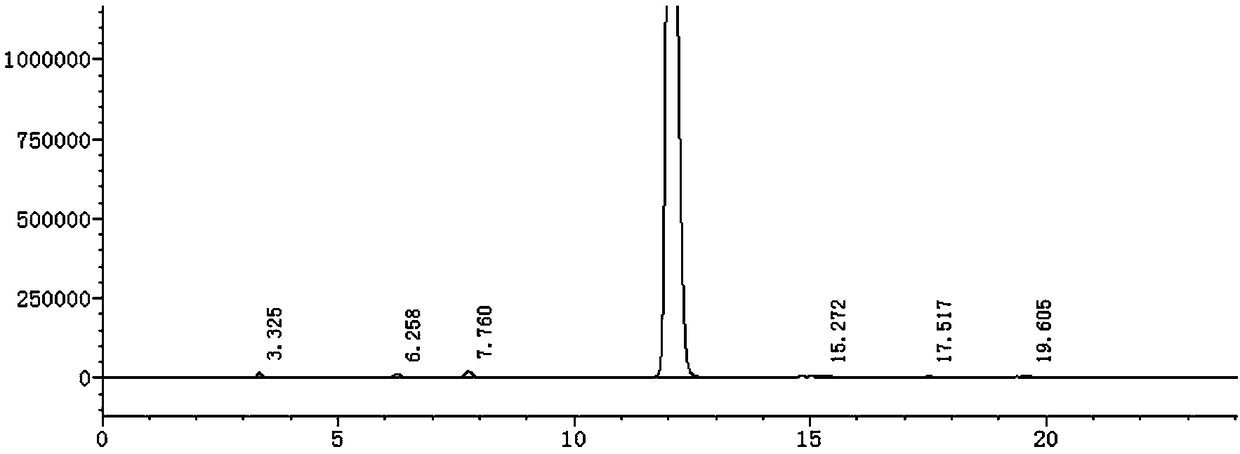

Embodiment 2

[0032] Dissolve 20 g of pentoxifylline recovered product (maximum single impurity 3.81%, total impurity 7.63%) in water, add 30% potassium hydroxide solution to adjust the pH value to 14, add reducing agent sodium triacetoxyborohydride 0.50 g, and keep warm at 80°C After 1h, filter and cool down to below 20°C to obtain an alkaline solution. The alkaline solution was mixed with dichloromethane, and the layers were separated after standing. After the organic phase was evaporated, a viscous liquid was obtained. Then add methanol to dissolve the viscous liquid, add charcoal and keep it at reflux temperature for 1 hour, remove the charcoal by hot filtration, and a large amount of pentoxifylline will be precipitated at room temperature, and the finished product will be obtained after cold filtration and drying. The yield is 80.9%, the maximum single impurity is 0.07%, and the total impurity is 0.44%.

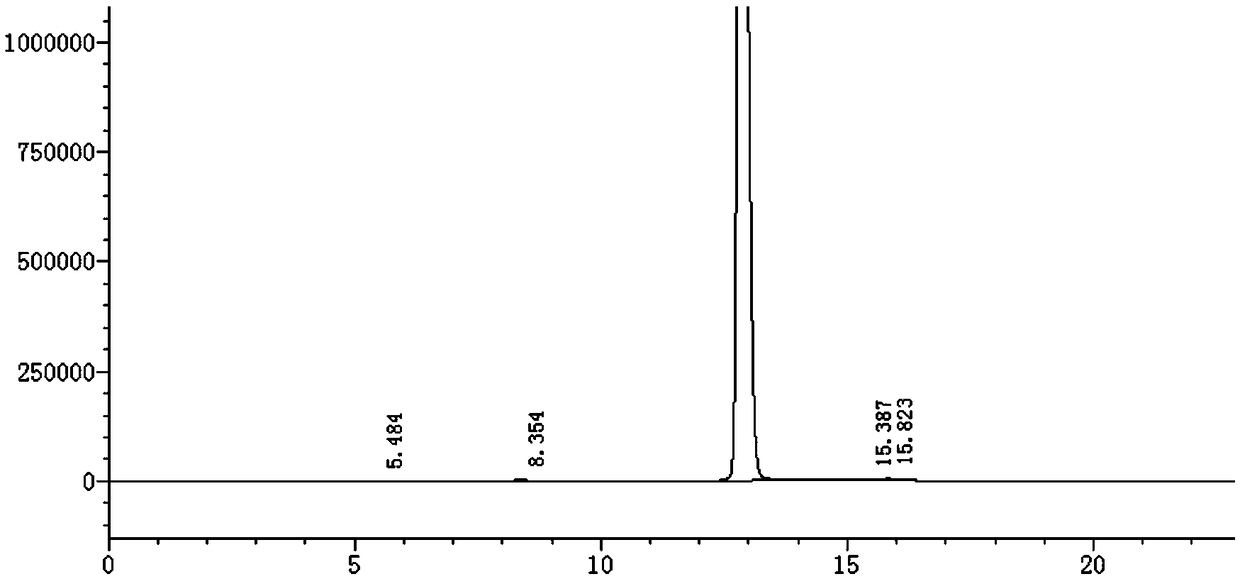

Embodiment 3

[0034] Dissolve 20 g of pentoxifylline recovered product (maximum single impurity 4.63%, total impurity 8.37%) in water, add 50% sodium carbonate solution to adjust pH value to 10, add reducing agent sodium triacetoxyborohydride 0.75 g, keep at 80°C for 1 hour , After filtering, cool down to below 20°C to obtain an alkaline solution. Mix this alkaline solution with toluene, let it stand for layers, and evaporate the organic phase to obtain a viscous liquid. Then add chloroform to dissolve the viscous liquid, add charcoal and keep it at the reflux temperature for 1 hour, remove the charcoal by hot filtration, and a large amount of pentoxifylline will be precipitated at room temperature, and the finished product will be obtained after cold filtration and drying. The yield is 83.6%, the maximum single impurity is 0.09%, and the total impurity is 0.41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com