Recycled concrete prepared from pipe pile centrifugal surplus paste

A recycled concrete and pipe pile centrifuge technology, applied in the field of recycled concrete, can solve the problems of low concrete strength, unstable strength development, fast setting speed of residual slurry, etc., and achieve stable strength development, excellent fluidity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

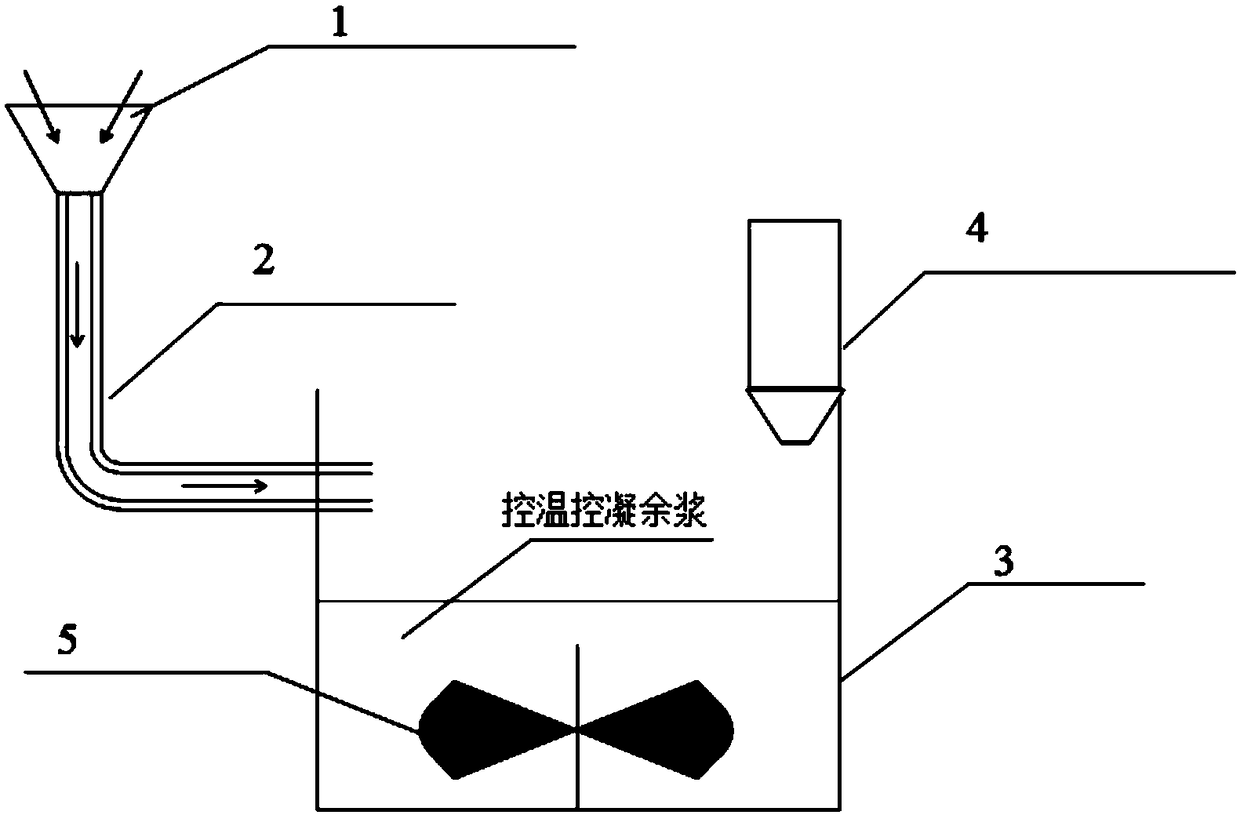

Method used

Image

Examples

Embodiment 1-3

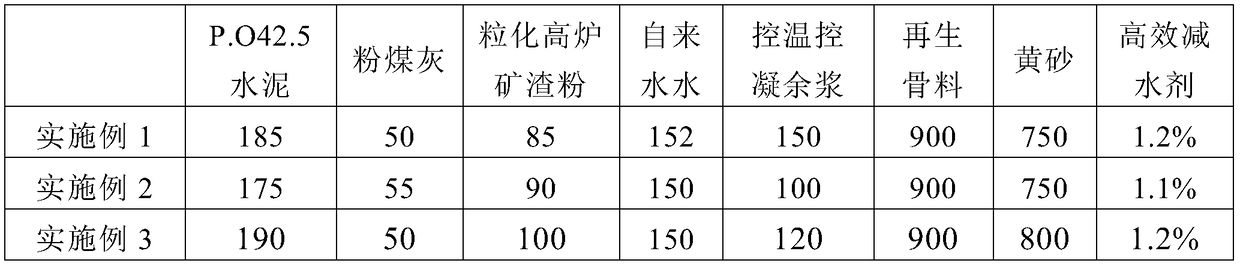

[0030] The proportioning ratio of the residual slurry for preparing recycled concrete in Examples 1-3 is shown in Table 1. The ultra-high performance recycled concrete is obtained after mixing and stirring the components evenly. The working performance and mechanical properties of the ultra-high performance concrete are shown in Table 2. Show.

[0031] Table 1 Unit: kg / m 3

[0032]

[0033] Remarks: The addition amount of high-efficiency water reducer in Examples 1-3 is 1.2%, 1.1%, and 1.2% of the sum of the weight of cement, fly ash, and granulated blast furnace slag powder, respectively.

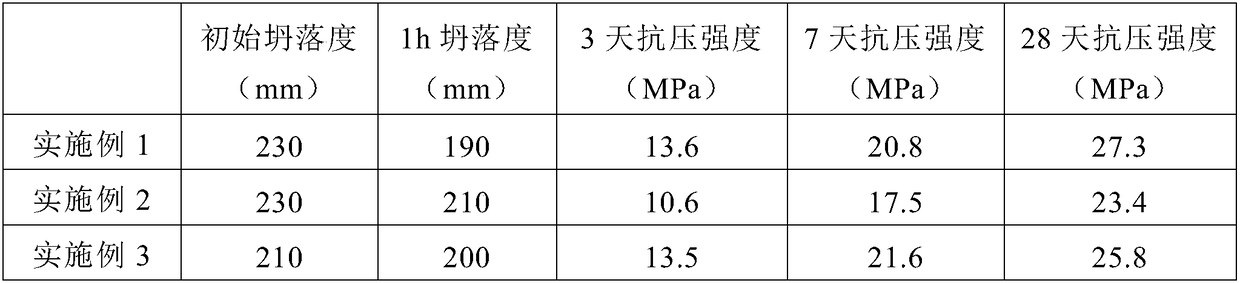

[0034] Table 2

[0035]

[0036] From the experimental results in Table 2, it can be seen that the recycled concrete prepared by using the centrifugal slurry of pipe piles in the present invention has an initial slump of 210-230 mm, and a 1-hour slump ≥ 190 mm. It has excellent fluidity and good workability. 3-day compressive strength: ≥10MPa; 7-day compressive strength: ≥15MPa; 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com