A method of riveting pcb circuit board using rivets

A PCB circuit board, rivet technology, applied in the direction of rivets, applications, household appliances, etc., to achieve the effect of solving scrap, strong positioning support, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

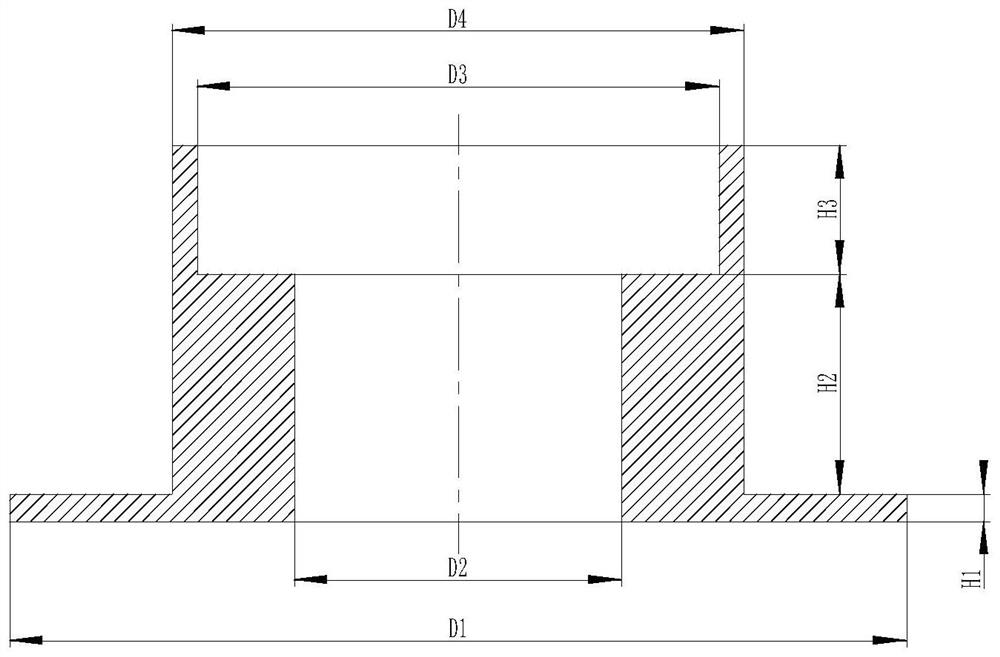

[0015] A method for pressing a PCB circuit board with rivets, the rivet is an inverted "T" structure, the center of the rivet is provided with a counterbore, and the diameter D1 of the flange at the bottom of the rivet is 2.0-8.0 mm, The height H1 of the flange plate at the bottom of the rivet is 0.1-1.0 mm, the small diameter D2 of the central counterbore hole of the rivet is 0.5-4.0 mm, the major diameter D3 of the central counterbore hole of the rivet is 1.0-4.5 mm, and the The outer diameter D4 of the upper end of the rivet is 1.5-5.0mm, the distance H2 between the large-diameter bottom surface of the rivet center counterbore and the top surface of the rivet bottom flange is 0.1-10.0mm, and the rivet top surface and the rivet center sink The distance H3 between the large-diameter bottom surfaces of the holes is 0.3-6.0 mm.

[0016] In an embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com