Water-purifying filter element structure

A filter element and water purification technology, which is applied in the fields of filtration and separation, membrane filter, filtration treatment, etc., can solve the problems of inability to filter, countercurrent, and stretched, so as to make full use of the space of the filter element, reduce the number of filter element stages, and increase the number of filter elements. The effect of the water inlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

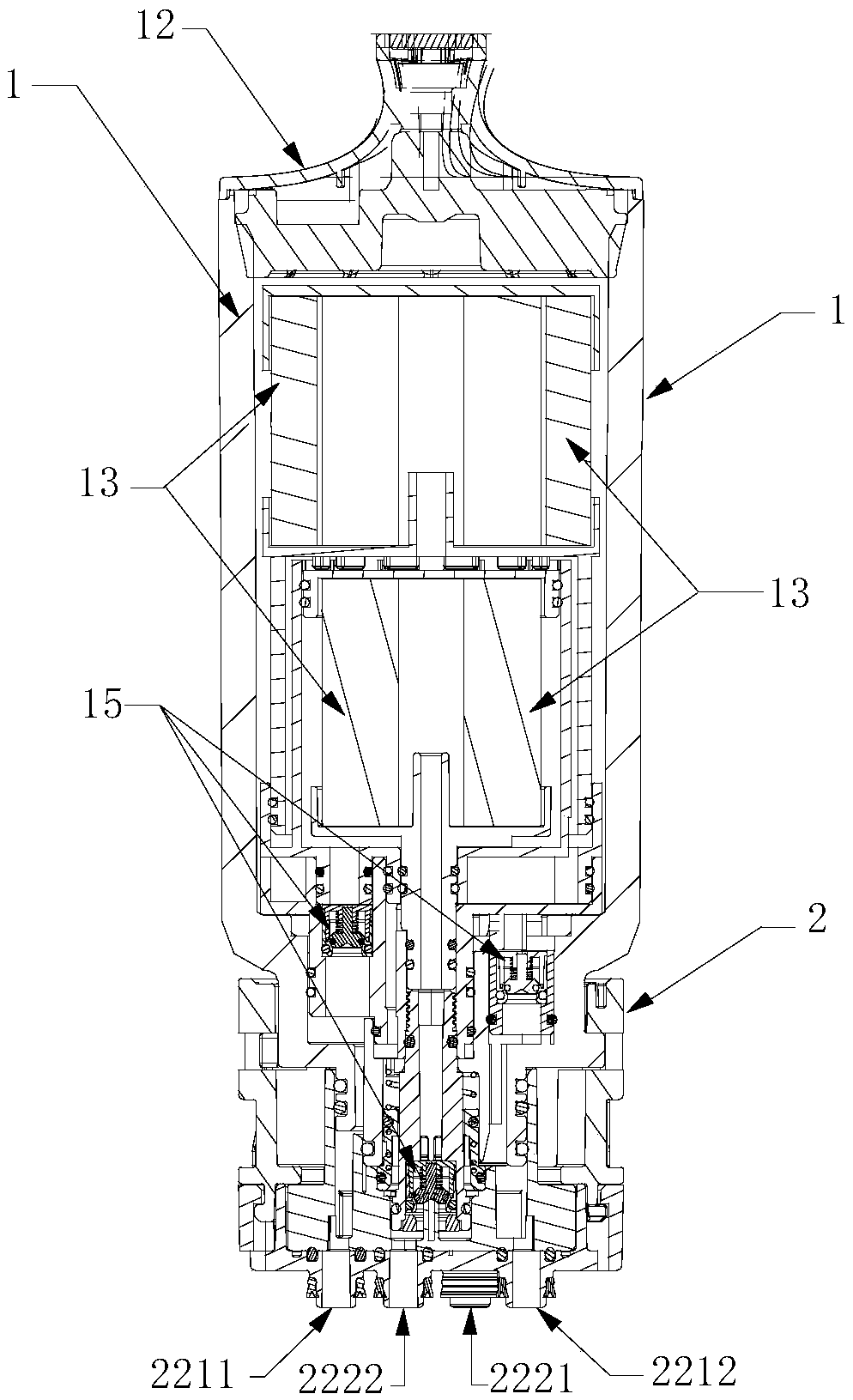

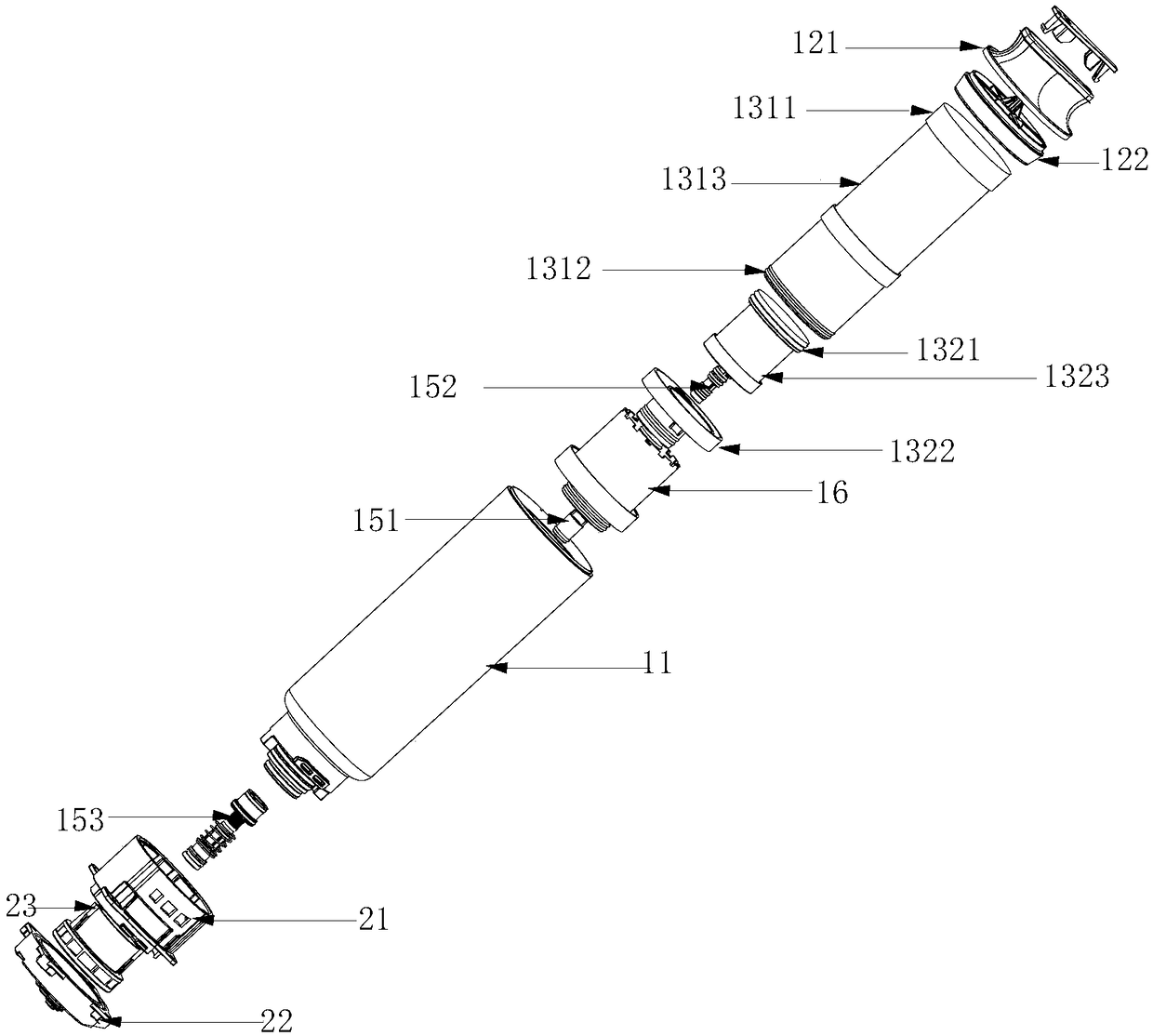

[0032] combine figure 1 with figure 2 As shown, this embodiment provides a water purification filter element structure, including a filter element body 1, and the filter element body 1 includes a filter cartridge 11, a filter cartridge cover 12, a filter body 13, a filter cavity 14, a non-return assembly 15, an inner guide Flow sleeve 16, O-ring 17 and lower fixing seat 18.

[0033] combine figure 1 with figure 2 As shown, the filter cartridge cover 12 includes a filter element cover 121 and a sealing cover 122, the filter cartridge cover 12 is arranged on the top of the filter cartridge 11, the sealing cover 122 is located below the filter element cover 121, and the filter element cover 121 is used to seal the filter cartridge 11 , and the sealing cover 122 is used to seal the filter body 13 .

[0034] combine figure 1 with figure 2 As shown, the filter body 13 is arranged in the filter cartridge 11, the filter body 13 includes an upper filter body 131 and a lower fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com