Total knee replacement operating table

A knee joint replacement and operating bed technology, which is applied to the field of knee joint replacement operating beds, can solve the problems of contaminating the operating bed, cumbersome cleaning, and inability to collect patient fluids, and achieves the effects of preventing damage and being easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

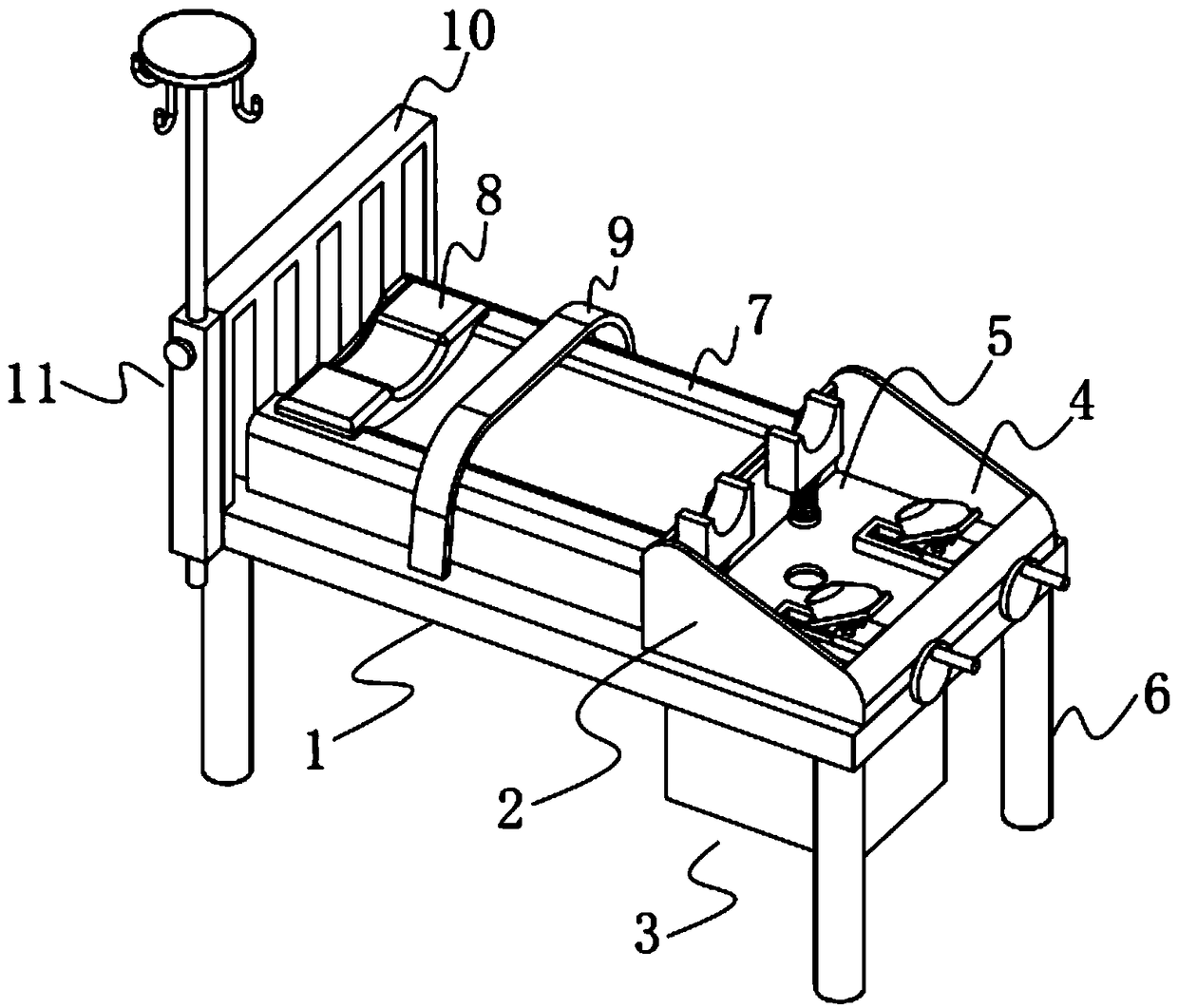

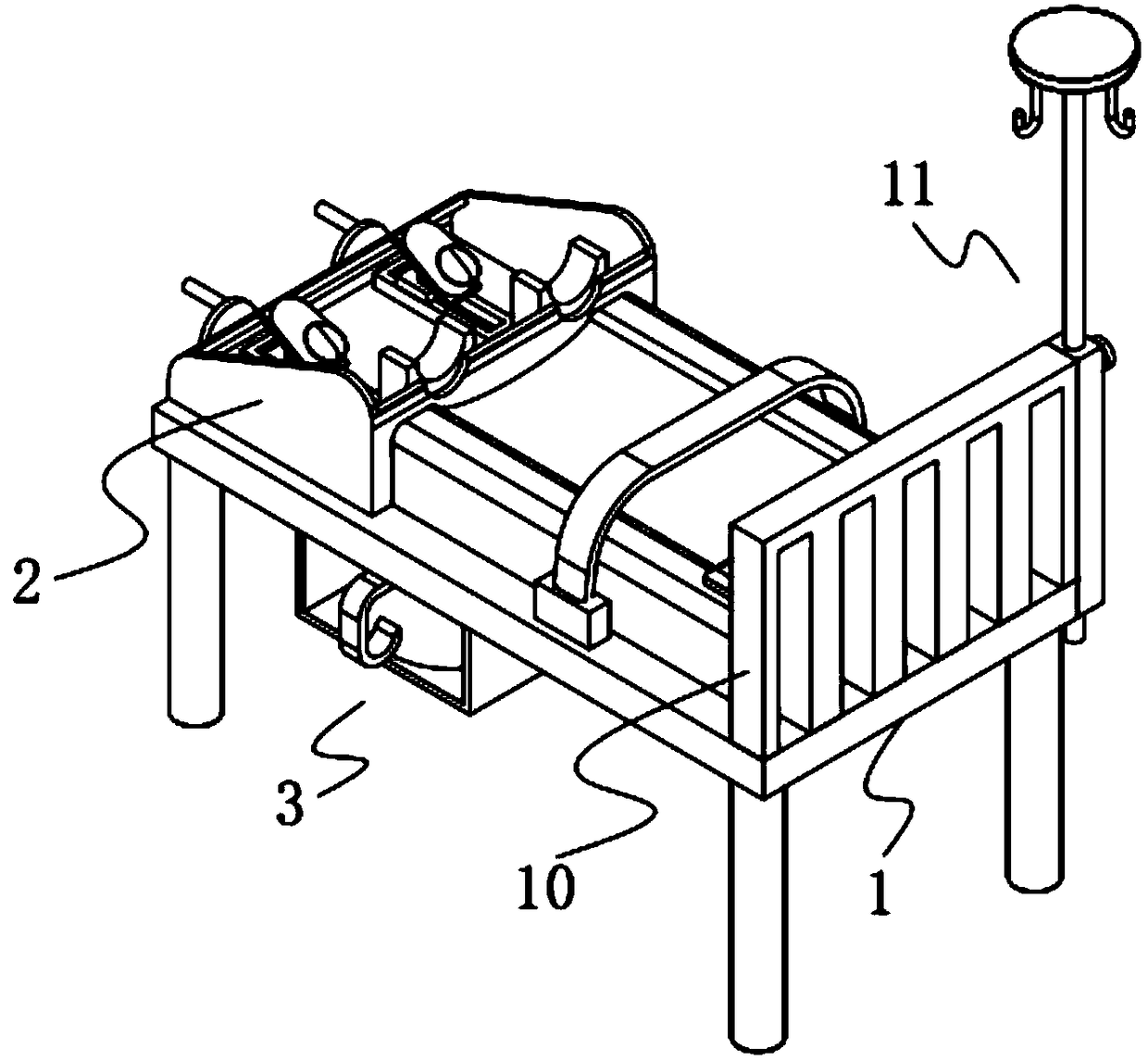

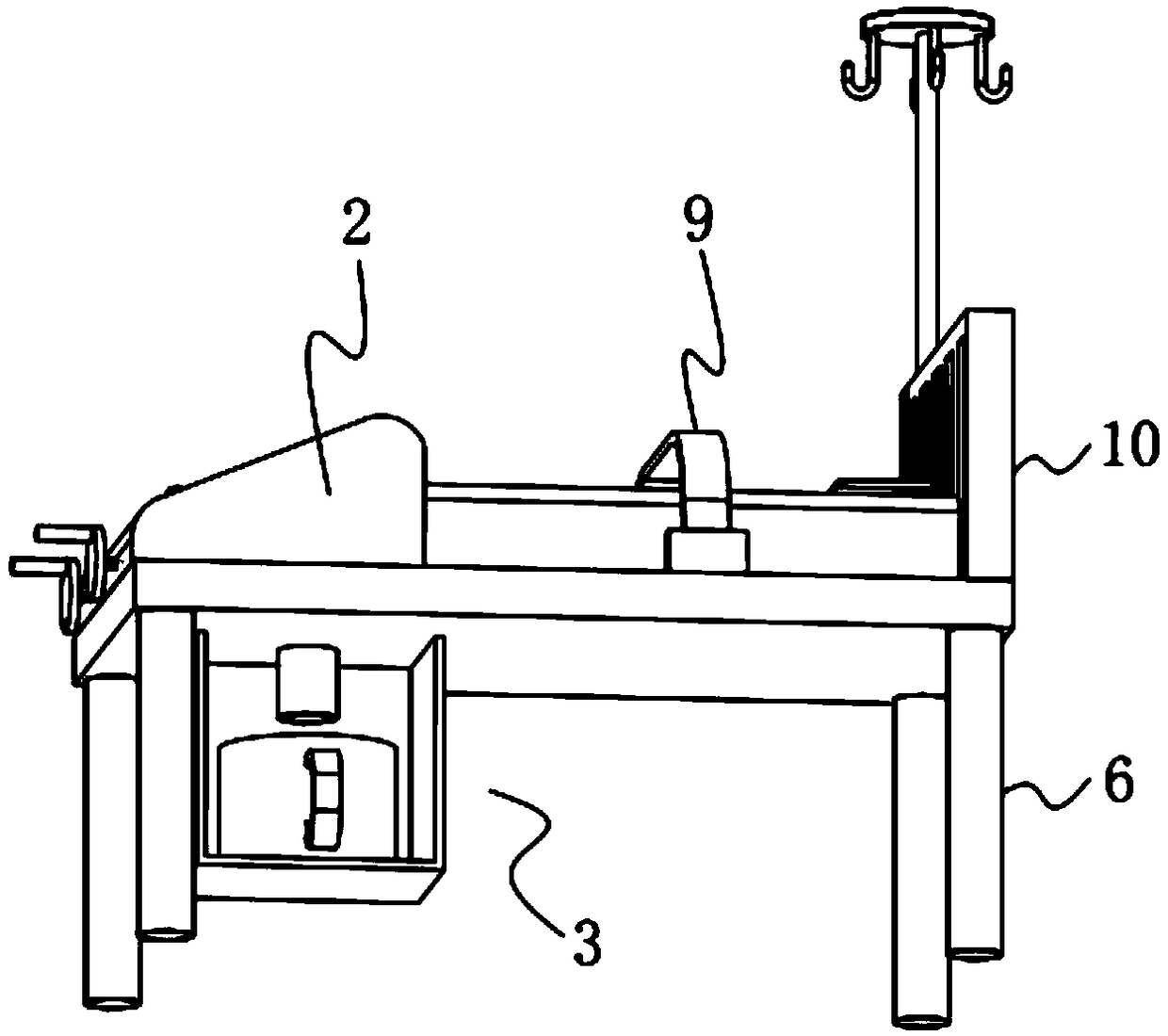

[0061] The following is attached Figure 1-16 The present invention is described in further detail.

[0062] An operating table for knee joint replacement, such as Figure 1-16 As shown, it includes a square bed board 1, four legs 6 are installed symmetrically at the four corners of the bottom of the square bed board 1, and the upper part of the square bed board 1 is fixedly installed with a shell 2 with an open structure at the top near one end thereof. Two sets of foot fixing units 4 are arranged symmetrically on the side wall near one end of the square bed board 1 inside the housing 2, and two U-shaped Groove 42, two groups of leg support units 5 are symmetrically arranged in the position close to the two U-shaped grooves 42 inside the housing 2, and a through hole 14 is opened on the bottom wall of the housing 2, and the square The bottom of the bed board 1 is located directly below the through hole 14, and a liquid storage unit 3 is fixedly installed;

[0063] The foot...

Embodiment 2

[0076] The difference from Example 1 is that the inner surface of the housing 2 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0077] Take the following raw materials and weigh them by weight: 20 parts of porcelain powder, 5 parts of titanium dioxide powder, 7 parts of mica powder, 6 parts of calcium carbonate powder, 10 parts of phenolic resin, 13 parts of epoxy resin, 5 parts of aluminum oxide powder, polyurethane 6 parts, 2 parts of triethanolamine, 3 parts of emulsified silicone oil, 1 part of fumed silica and 40 parts of water;

[0078] S1. Add the weighed triethanolamine, emulsified silicone oil and water into the mixer and stir for 20min at a stirring speed of 600r / min to prepare a mixed solution;

[0079] S2. Add porcelain powder, titanium dioxide powder, mica powder, calcium carbonate powder, phenolic resin, epoxy resin, aluminum oxide powder, polyurethane and fumed silica into a ball mill for fine grinding un...

Embodiment 3

[0085] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0086] Take the following raw materials and weigh them by weight: 25 parts of porcelain powder, 7 parts of titanium dioxide powder, 8 parts of mica powder, 7 parts of calcium carbonate powder, 12 parts of phenolic resin, 15 parts of epoxy resin, 8 parts of aluminum oxide powder, polyurethane 8 parts, 3 parts of triethanolamine, 4 parts of emulsified silicone oil, 2 parts of fumed silica and 50 parts of water;

[0087] S1. Add the weighed triethanolamine, emulsified silicone oil and water into the mixer and stir for 25min at a stirring speed of 700r / min to prepare a mixed solution;

[0088] S2. Add porcelain powder, titanium dioxide powder, mica powder, calcium carbonate powder, phenolic resin, epoxy resin, aluminum oxide powder, polyurethane and fumed silica into a ball mill for fine grinding until the particle diameter is 30um to obtain a mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com