Roller-type tobacco feeding machine with composite-type heating system

A heating system, drum-type technology, applied in tobacco, cigarette manufacturing, application, etc., can solve the problems of affecting the moisture of the material outlet, reducing the stability of process parameters, and difficult to control the temperature of the material, so as to reduce labor intensity and ensure equipment operation stability Improvement and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

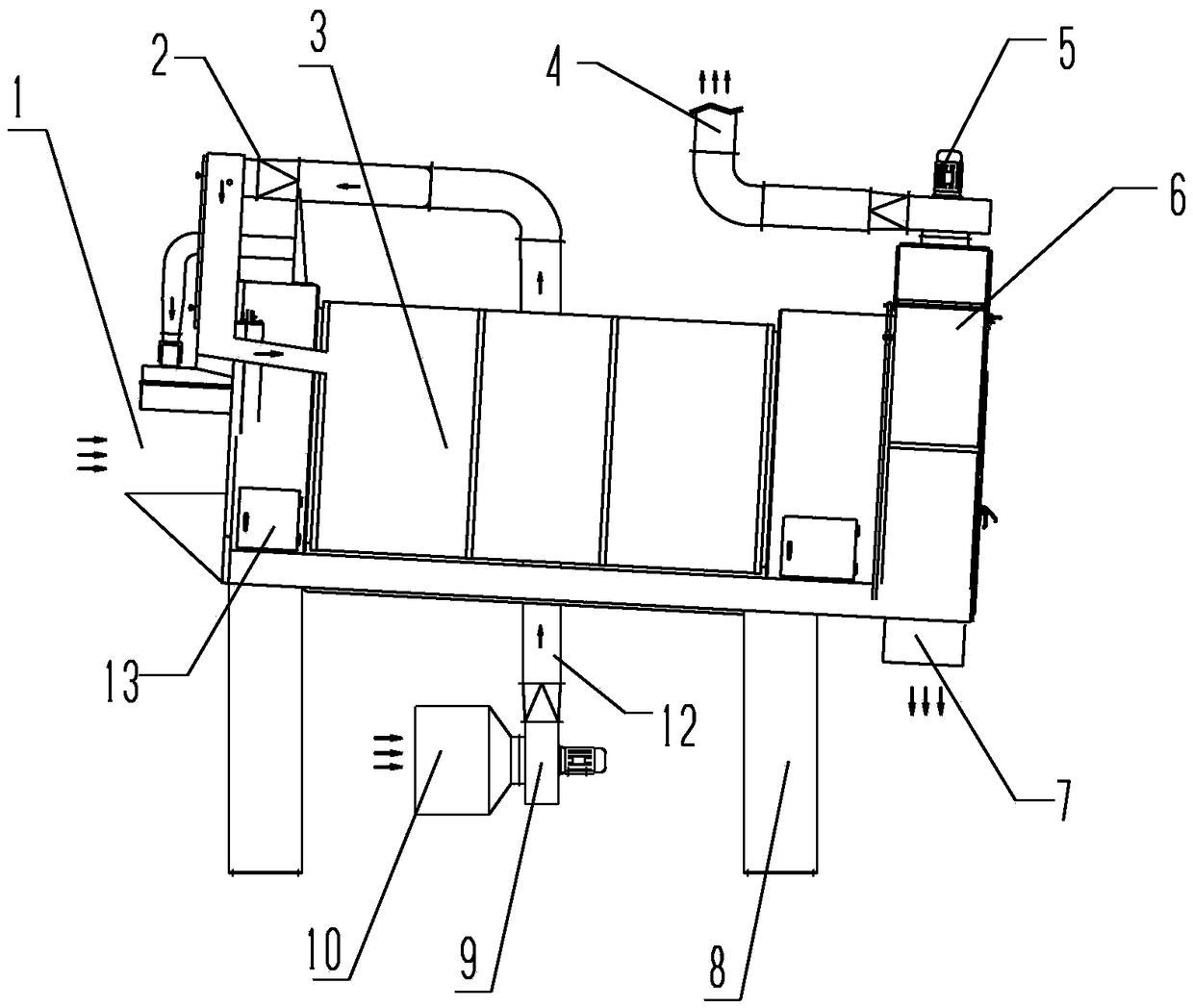

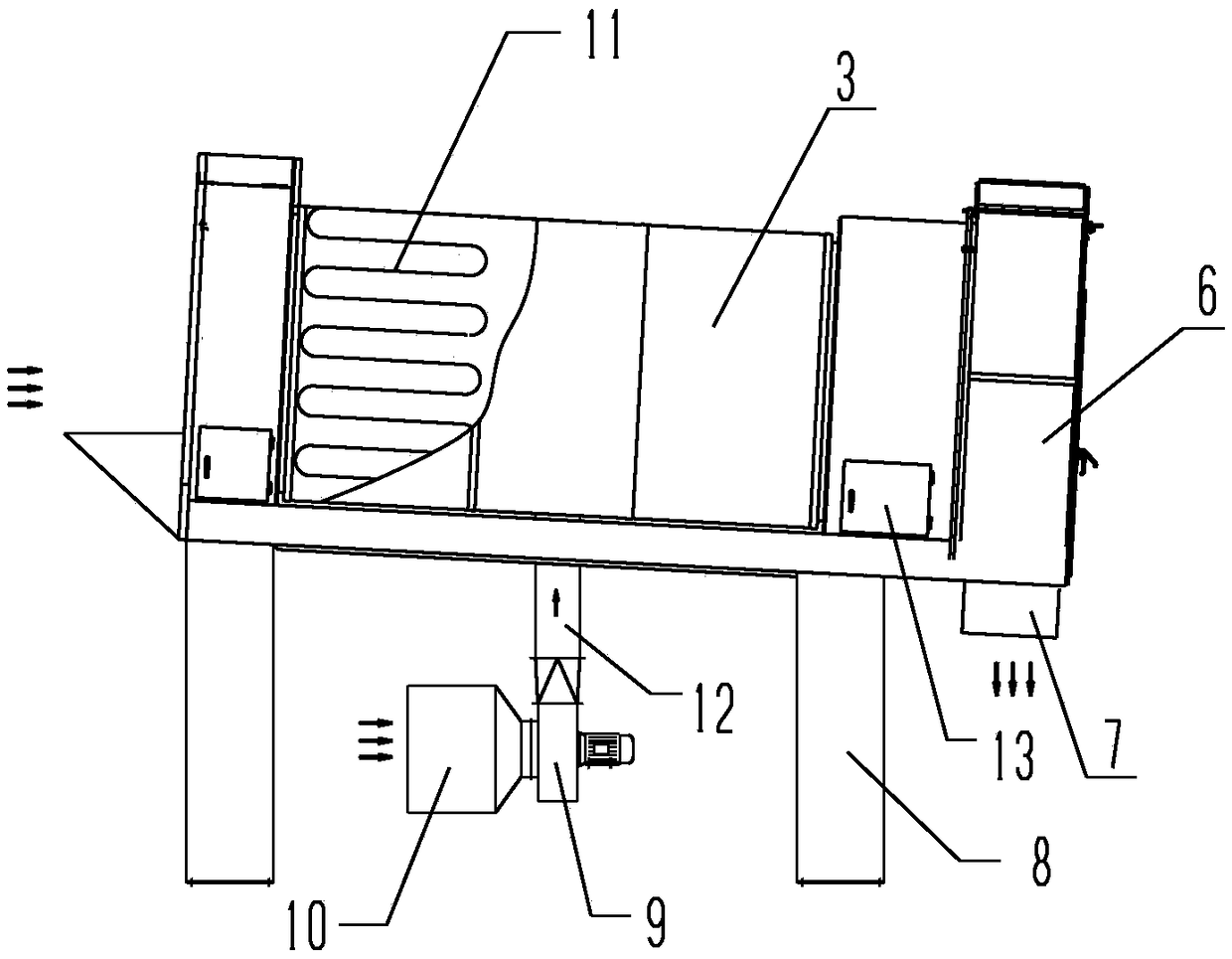

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Figure 1 and figure 2 The tobacco leaf drum feeder of a compound heating system shown includes a frame 8, a material conveying roller 3 inclinedly arranged on the frame 8, a transmission device 13 and a hot air circulation system arranged on the material conveying roller 3, The inclination angle of the material conveying roller 3 is 10-20°, a feed chamber 1 is provided on the higher side of the material conveying roller 3, and a discharge port 7 is provided on the lower side. The frame 8 is mainly used to support the material conveying roller 3, and the transmission device 13 is the same as the existing roller transmission device, and mainly plays a role in driving the roller. The hot air circulation system is composed of a hot air circulation pipe 2, a hot air blower 9 and a radiator 10. One end of the hot air circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com