Method for prolonging quality guarantee period of egg liquid

A shelf life and egg liquid technology, which is applied in egg preservation, food preservation, egg preservation through freezing/cooling, etc., can solve the problems of poor quality, liquid egg functional property damage, and odor, so as to improve thermal conductivity and electrical conductivity , The effect of improving the sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

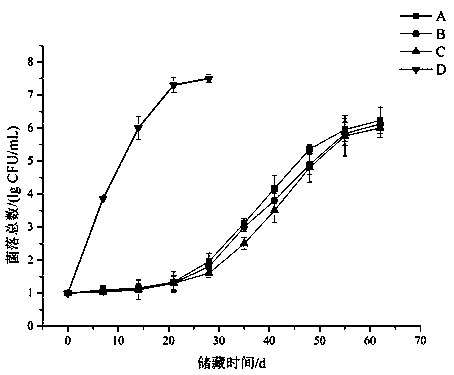

Image

Examples

Embodiment 1

[0025] A production method for extending the shelf life of egg liquid, the specific steps are as follows.

[0026] (1) Pre-treatment: Select fresh and complete poultry eggs, wash them with clean water, immerse them in 40°C disinfectant water containing 220ppm sodium hypochlorite for 120 seconds, dry them with hot air at 40°C, beat the eggs, and then separate the protein liquid and egg yolk liquid Or the whole egg liquid is obtained without separation, and the egg liquid is filtered and stirred evenly to obtain the spare egg liquid.

[0027] (2) Adding the compound: by mass percentage, 0.15% of propylene glycol and 0.01% of potassium cinnamate were added to the egg liquid obtained in step (1).

[0028] (3) High-pressure homogenization: the egg liquid obtained in step (2) is subjected to high-pressure homogenization at a pressure of 25 MPa.

[0029] (4) Pasteurization: The egg liquid obtained in step (3) was subjected to pulsed electric field-assisted pasteurization at a field ...

Embodiment 2

[0033] A liquid egg production method with stable quality, the specific steps are as follows.

[0034] (1) Pre-treatment: select fresh and complete poultry eggs, wash them with clean water, immerse them in 45°C disinfectant water containing 280ppm sodium hypochlorite for 160s, dry them with hot air at 50°C, beat the eggs, and separate the protein liquid and egg yolk liquid after beating Or the whole egg liquid is obtained without separation, and the egg liquid is filtered and stirred evenly to obtain the spare egg liquid.

[0035] (2) Add compound stabilizer: by mass percentage, add 0.3% propylene glycol and 0.1% potassium cinnamate to the egg liquid obtained in step (1).

[0036] (3) High-pressure homogenization: the egg liquid obtained in step (2) is subjected to high-pressure homogenization at a pressure of 35 MPa.

[0037] (4) Pasteurization: The egg liquid obtained in step (3) was subjected to a pulsed electric field-assisted pasteurization treatment with a field strengt...

Embodiment 3

[0041] A production method for extending the shelf life of egg liquid, the specific steps are as follows.

[0042] (1) Pre-treatment: select fresh and complete poultry eggs, wash them with clean water, immerse them in 42°C disinfectant water containing 250ppm sodium hypochlorite for 140 seconds, dry them with hot air at 45°C, beat the eggs, and separate the protein liquid and egg yolk liquid after beating Or the whole egg liquid is obtained without separation, and the egg liquid is filtered and stirred evenly to obtain the spare egg liquid.

[0043] (2) Adding the compound: by mass percentage, 0.23% propylene glycol and 0.06% potassium cinnamate were added to the egg liquid obtained in step (1).

[0044] (3) High-pressure homogenization: The obtained product in step (2) is homogenized under a high pressure of 30 MPa.

[0045] (4) Pasteurization: The egg liquid obtained in step (3) was subjected to a pulsed electric field-assisted pasteurization treatment with a field strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com