Motor stator aluminum enameled wire head welding process

A motor stator and welding process technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as unreliable welding, difficult tinning of aluminum wires, and difficult manual work, and achieve stable product quality and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

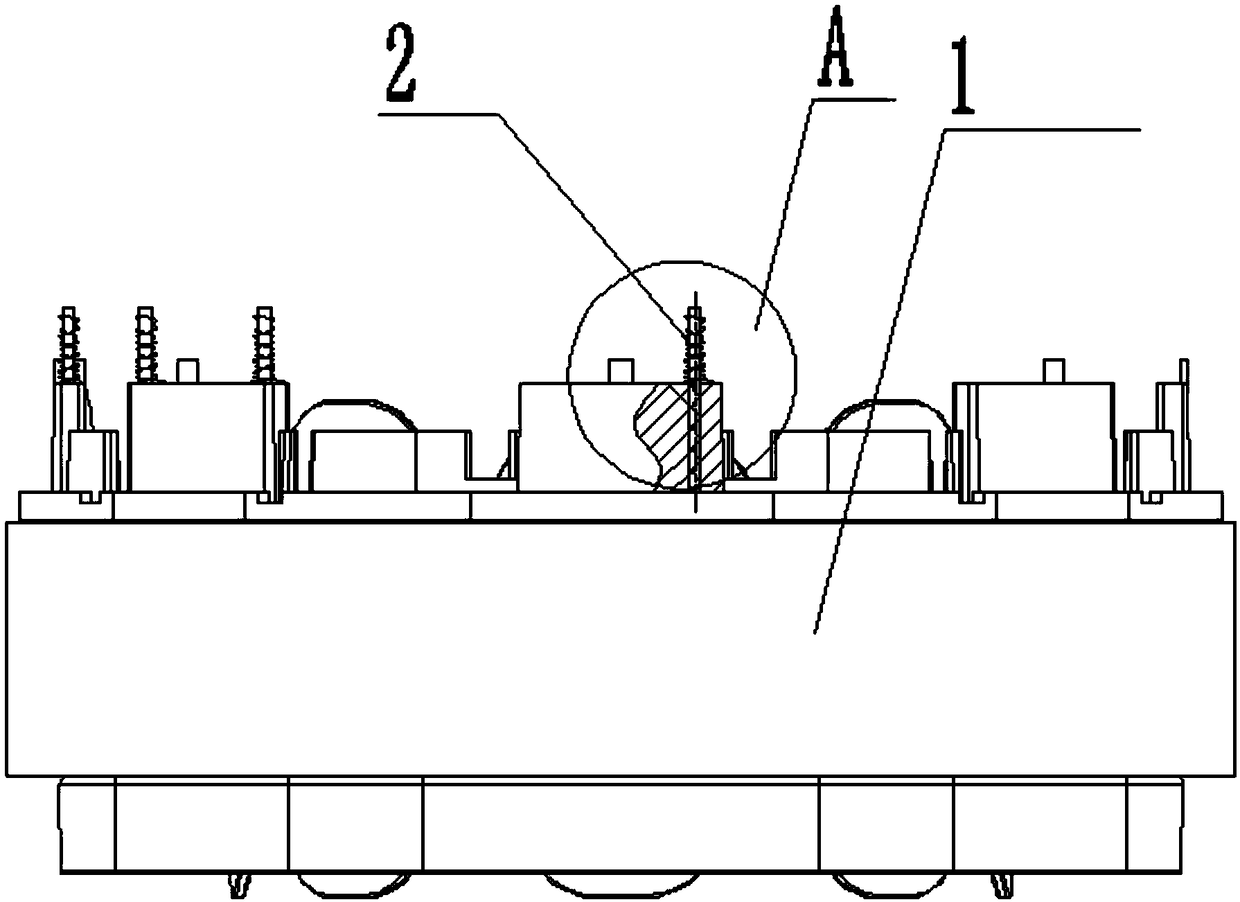

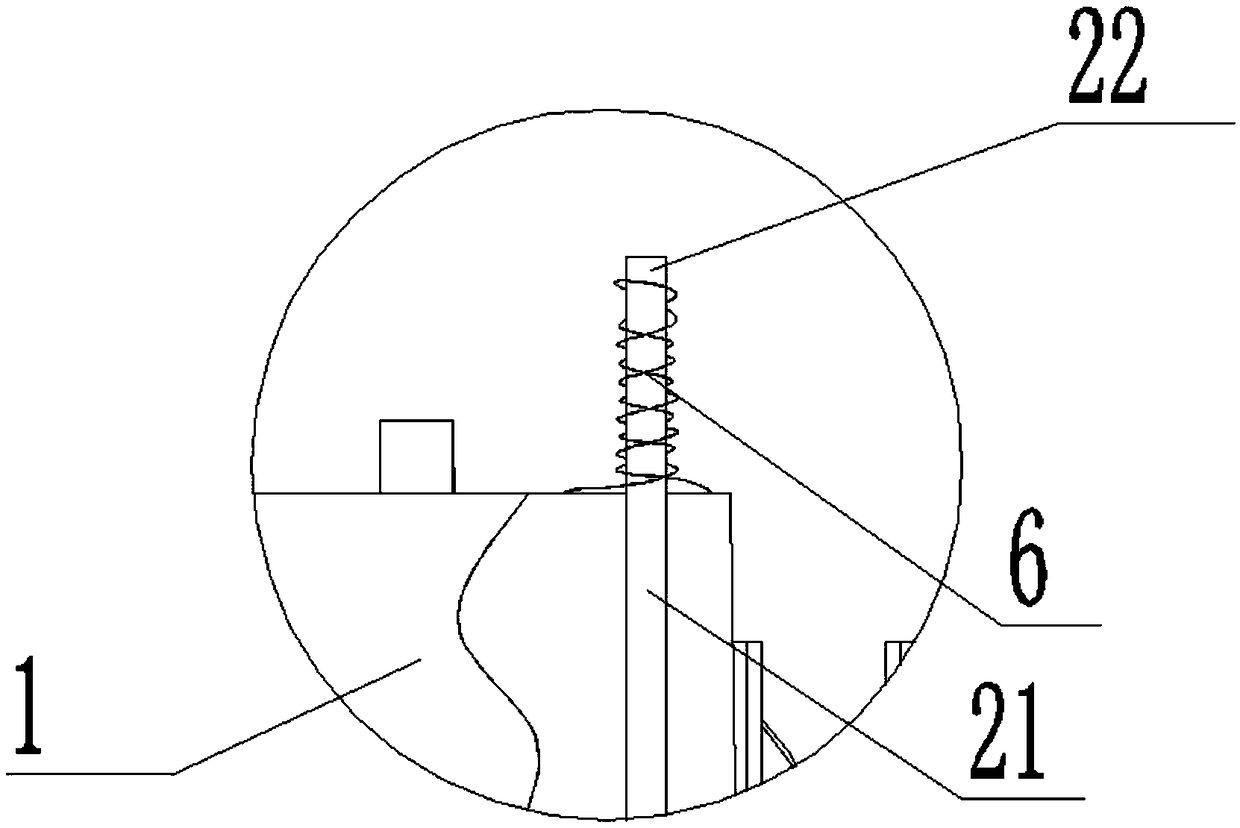

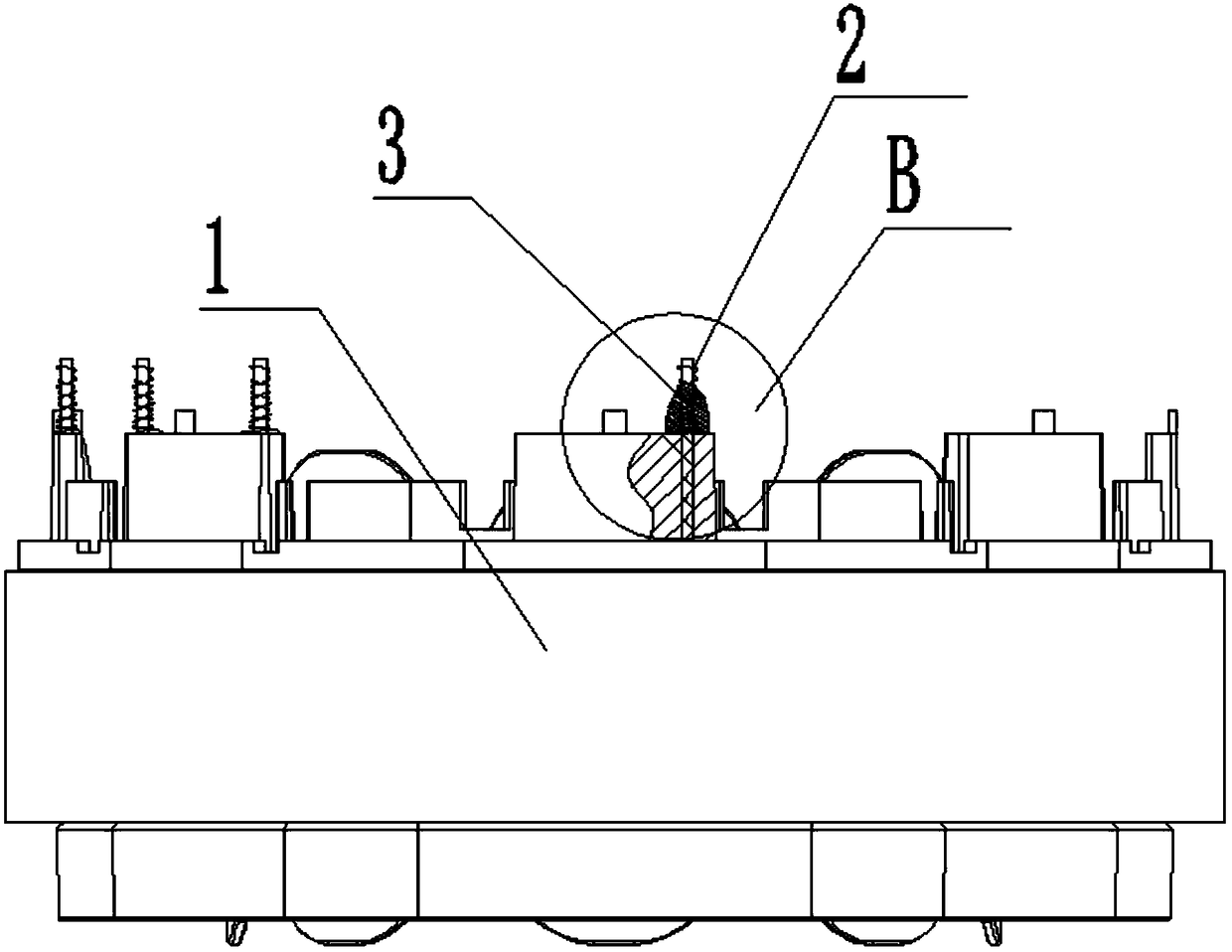

[0033] Such as Figure 1-6 As shown, a kind of motor stator aluminum enameled wire head welding process provided by the invention, concrete steps are as follows:

[0034] (1) Automatically wind the enamelled aluminum wire 6 on the pin 2 of the motor stator 1 by using a winding device;

[0035] (2) Carry out the first section of welding at the winding place of the enamelled aluminum wire 6 of the motor stator 1, soak the flux, and then solder for 1-5 seconds;

[0036] (3) Dip flux again, and then solder for 1 to 5 seconds;

[0037] (4) Apply the first section of sealant 3 to the first section of the welded part.

[0038] The aluminum wire is firmly welded to other metal parts, which greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com