A fully automatic integrated assembly line and processing technology for ethylene-propylene rubber compounding rubber

A processing technology, ethylene propylene rubber technology, applied in coating and other directions, can solve the problems of insufficient uniform product quality, high labor intensity of workers, and different dosages, etc., to achieve fully automated production, stable product quality and performance, and accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

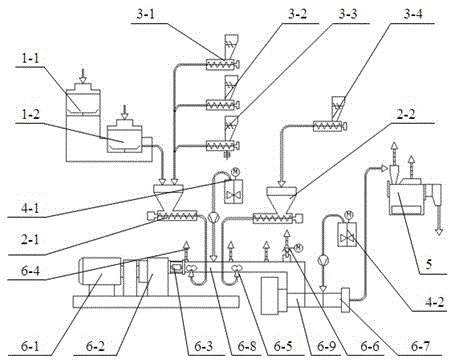

[0034] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

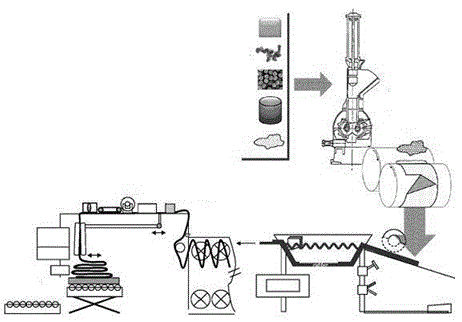

[0035]The invention provides a fully automatic integrated assembly line and processing technology for ethylene-propylene rubber mixing rubber. The production line can continuously and automatically produce ethylene-propylene rubber in the field of rubber production. All production is continuous mixing for 24 hours without interruption. The powder and granules are uniformly distributed by the warehouse pipeline, and there is no leakage of the material. Therefore, the produced mixed rubber has a high degree of cleanliness and stable product quality and performance.

[0036] A kind of processing technology of ethylene-propylene rubber mixed rubber of the present invention, described processing step is as follows:

[0037] 1) Weigh the required ethylene-propylene masterbatch and ethylene-propylene masterbatch through the ethylene-propylene masterbatch weighing feeder 1-1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com