Crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of high cost of passivation on the back of crystalline silicon solar cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 4

[0085] The present invention also provides a method for manufacturing a crystalline silicon solar cell, and a schematic flow chart of a specific implementation thereof is as follows: Figure 5 As shown, it is referred to as the fourth specific embodiment, including:

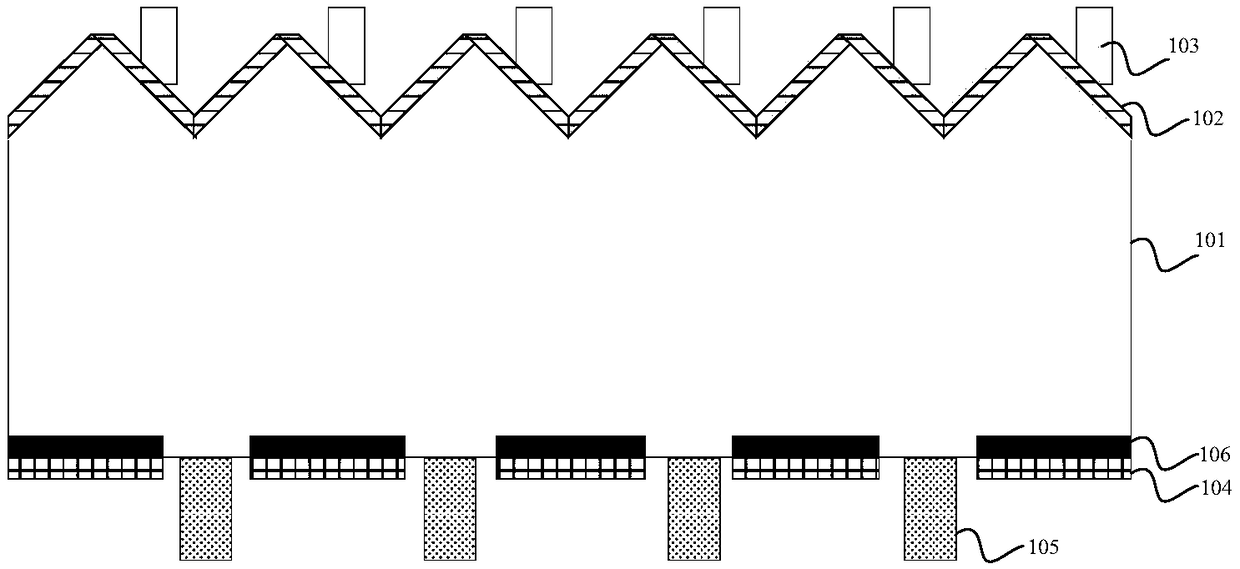

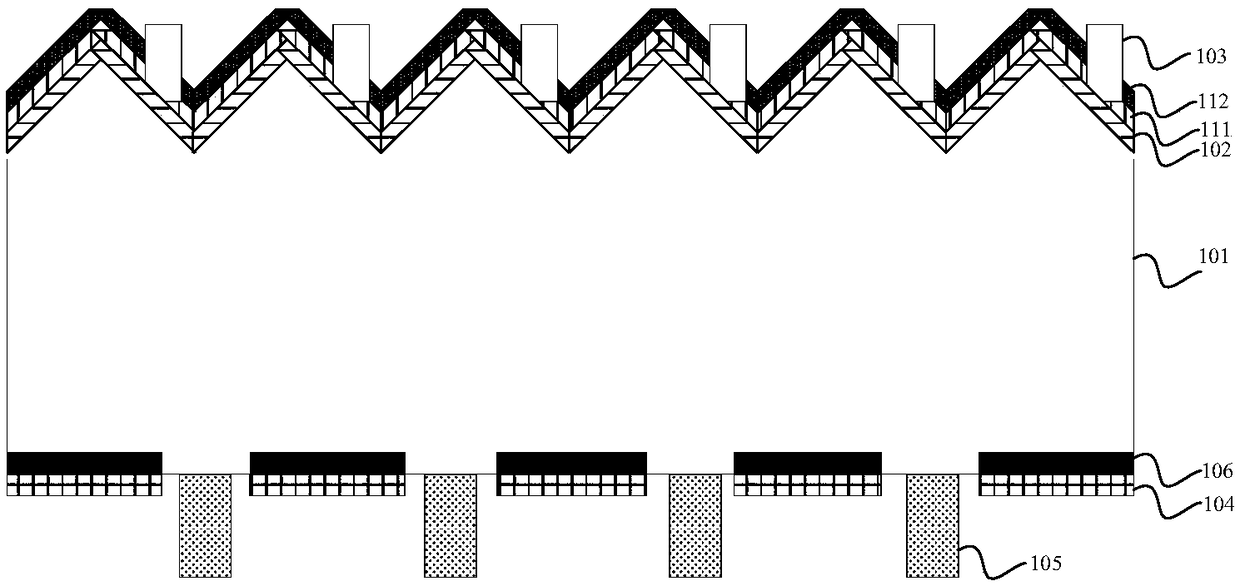

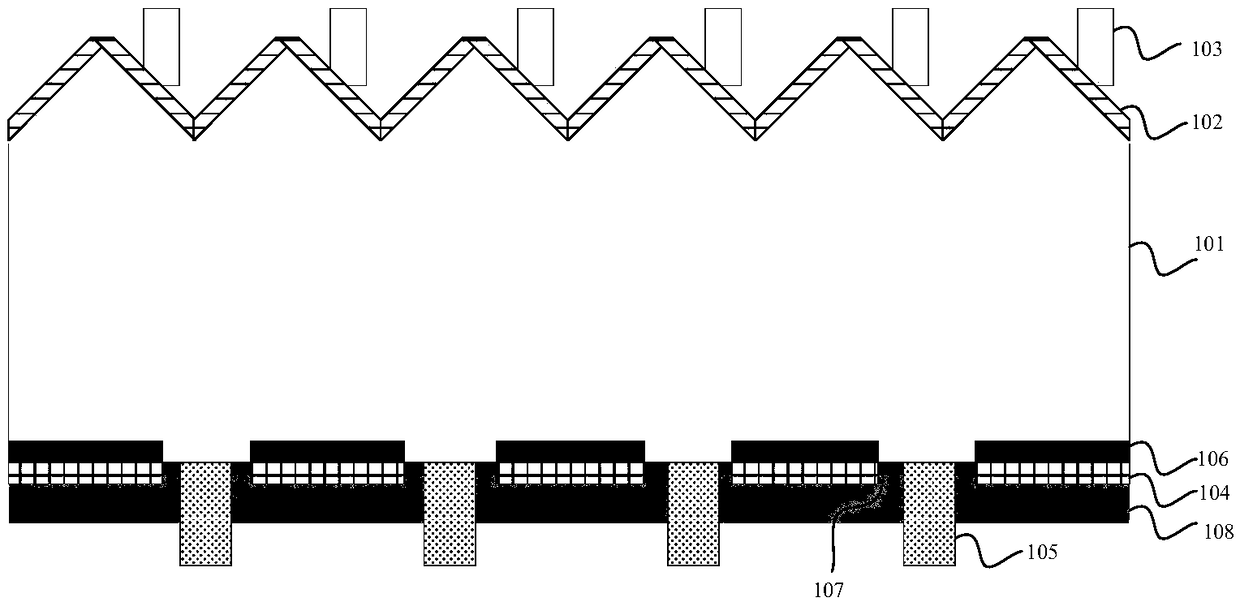

[0086] Step S101 : providing a P-type substrate 101 .

[0087] Furthermore, the above-mentioned P-type substrate 101 is also processed by one or more of the processes of cleaning, cutting damage removal, and surface texturing.

[0088] Step S102: disposing an N-type semiconductor layer 102 on the light-receiving surface of the above-mentioned P-type substrate 101 .

[0089] Step S103 : setting a dielectric layer 104 on the backlight surface of the P-type substrate 101 , the dielectric layer 104 is a dielectric layer 104 with a high fixed positive charge.

[0090] Furthermore, the dielectric layer 104 is set to deposit a silicon nitride layer on the back side by PECVD (PlasmaEnhanced Chemical Vapor Deposition) m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com