Glass steel pipeline on-site repair assembly and method

A glass fiber reinforced plastic and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of pipeline leakage and difficult quality assurance, and achieve the effect of improving construction efficiency and saving precious time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

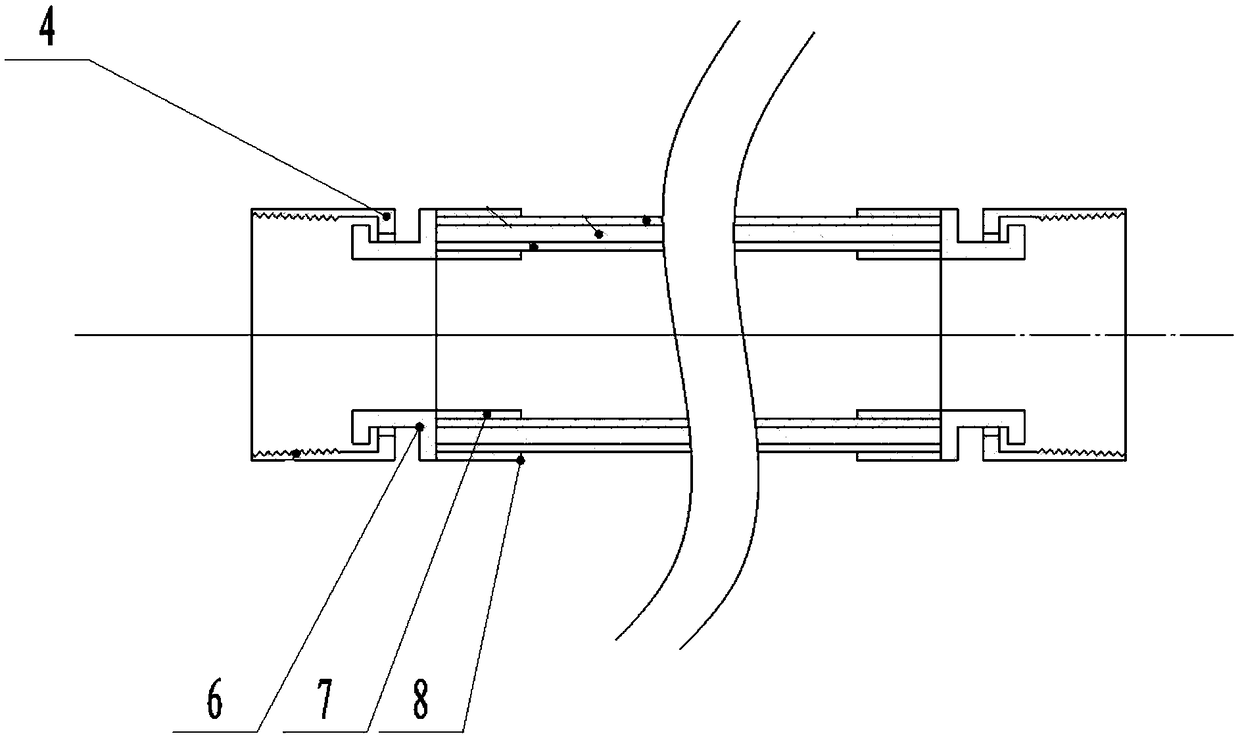

[0038] On-site repair of glass steel pipes (DN100PN4MPa) with 10cm axial cracks in the pipeline

[0039] Step 1: Identify and confirm the failure position of the failed FRP pipe on site, and select components according to the length of the failure position, among which the length of the connection nipple is selected to be 50cm, the conversion nipple is selected to be DN80 to DN100, and the repair nipple is selected to be DN100 ;

[0040] Step 2: Taking the crack of the pipe body as the center, measure the damaged part of the pipe body with a length of 90cm (50cm is the length of the connection nipple, and 40cm is the length of the 2 conversion nipples) and cut it. Grind the tapered surface at the position where the length of the ends of the two pipelines to be repaired is 10cm, and the taper is consistent with the taper of the female end of the repaired short joint.

[0041] Step 3: Apply the blended A and B component adhesives to the polished outer tapered surface of the end...

Embodiment 2

[0046] On-site repair of glass steel pipes (DN80PN6MPa) with 50cm leakage at the corner of the pipeline

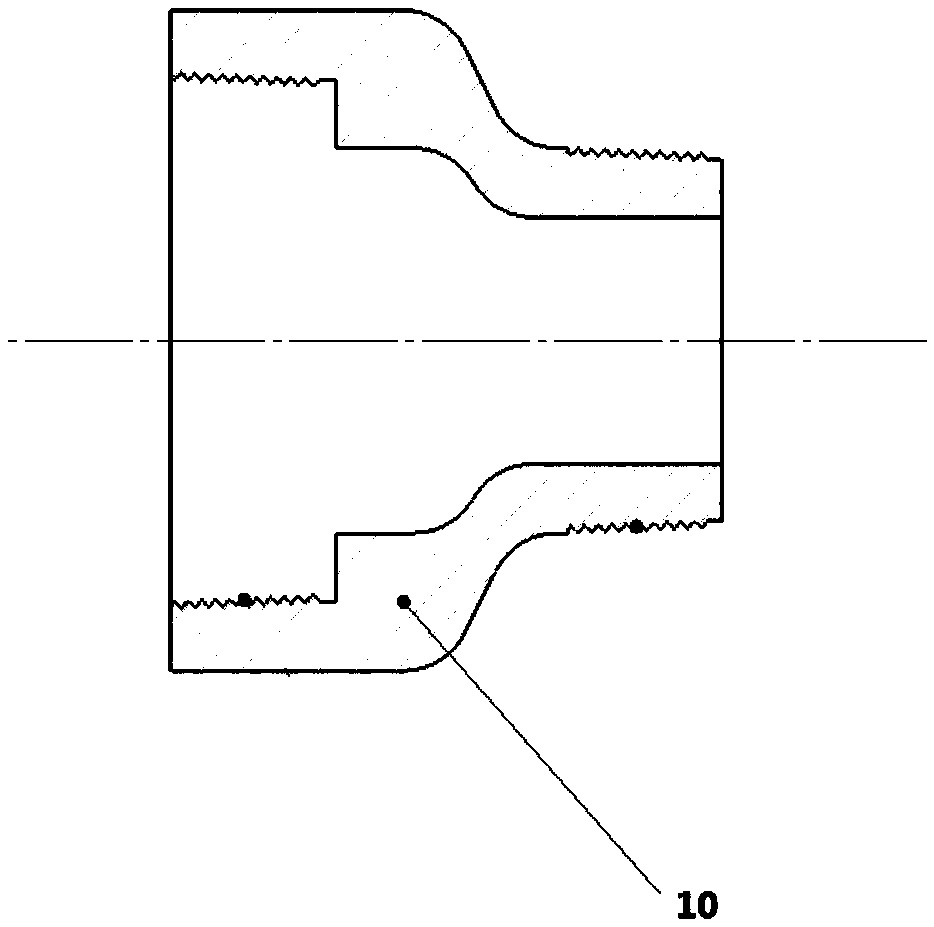

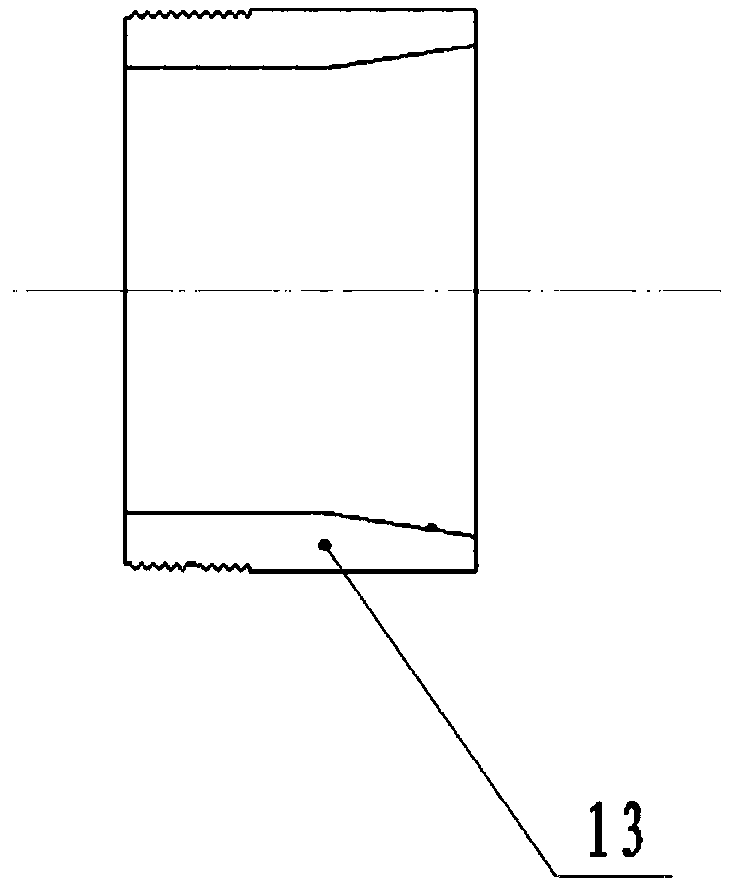

[0047] Step 1: Identify and confirm the failure position of the failed FRP pipe on site, and select components according to the length of the failure position, wherein the selected length of the connecting puppet is 200cm, and the selected specification of the repaired end puppet (13) is DN100. Since the diameter of the pipeline to be repaired is the same as that of the connecting nipple, the conversion nipple of the second part of the component is not selected in this example;

[0048] Step 2: Taking the crack of the pipe body as the center, measure the damaged part of the pipe body with a length of 200cm and saw it. Grind the tapered surface at the position where the length of the ends of the two pipelines to be repaired is 10cm, and the taper is consistent with the taper of the female end of the repaired short joint.

[0049] Step 3: Apply the blended A and B component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com