Construction technology of waterproof air-permeable bare-concrete-simulation coating

A technology imitating fair-faced concrete and construction technology, applied in coatings, buildings, building structures, etc., can solve problems such as high cost, affecting coating quality, and difficulty in repairing defects, etc., to reduce production costs, combine tightly and reliably, Increase the effect of anti-graffiti

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

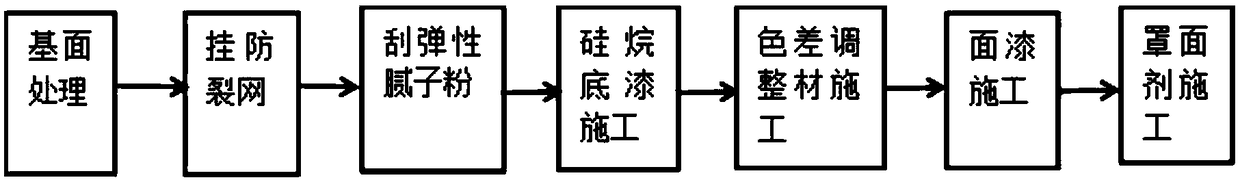

Method used

Image

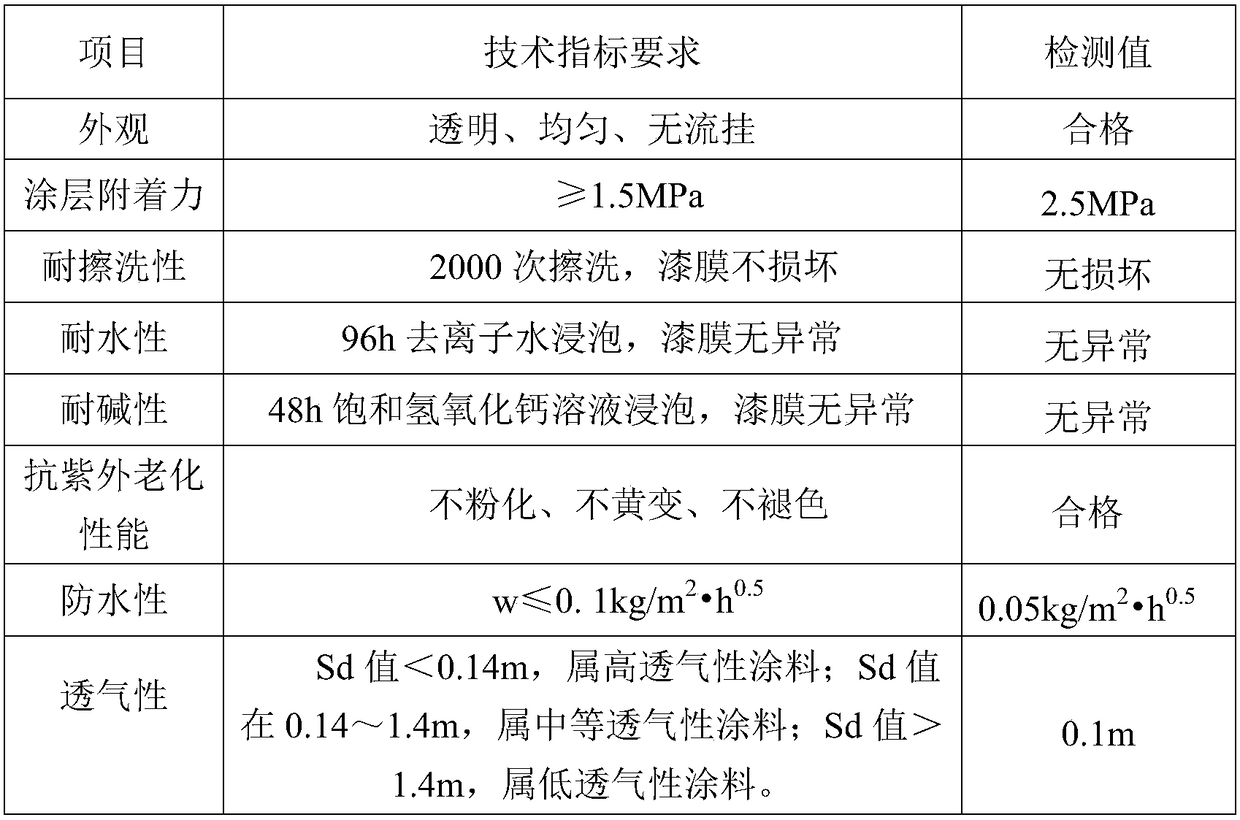

Examples

Embodiment 2

[0048] (1) base surface treatment

[0049] Except that the filling material is gray elastic putty powder, water is evenly prepared at a mass ratio of 1:0.6, the putty is putty powder, and water is evenly prepared at a mass ratio of 1:0.6, the rest is the same as step (1) in Example 1;

[0050] (2) primer construction is identical with step (2) in embodiment 1;

[0051] (3) Construction of color difference adjustment material

[0052] Except that the formulas of silicone resin adjustment material, color correcting agent A, color correcting agent B, and color correcting agent C are different, the rest are the same as step (3) in Example 1;

[0053] Among them, the silicone resin adjustment material includes the following components in mass percentage: 33% of water, 26% of pure acrylic emulsion, 15% of silicone emulsion, 15% of natural stone powder, 9% of talcum powder, 0.3% of defoamer, preservative 0.5%, dispersant 0.4%, thickener 0.8%;

[0054] The silicone resin adjustment m...

Embodiment 3

[0057] (1) base surface treatment

[0058] Except that the filling material is gray elastic putty powder, water is evenly prepared at a mass ratio of 1:0.7, the putty is putty powder, and water is evenly prepared at a mass ratio of 1:0.7, the rest is the same as step (1) in Example 1;

[0059] (2) primer construction is identical with step (2) in embodiment 1;

[0060] (3) Construction of color difference adjustment material

[0061] Except that the formulas of silicone resin adjustment material, color correcting agent A, color correcting agent B, and color correcting agent C are different, the rest are the same as step (3) in Example 1;

[0062] Among them, the silicone resin adjustment material includes the following components in mass percentage: 27.8% of water, 28% of pure acrylic emulsion, 14% of organic silicon emulsion, 18% of natural stone powder, 10% of talcum powder, 0.5% of defoamer, preservative 0.4%, dispersant 0.3%, thickener 1%;

[0063] The silicone resin ad...

Embodiment 4

[0066] (1) base surface treatment

[0067] Except that the filling material is gray elastic putty powder, water is evenly prepared at a mass ratio of 1:1, the putty is putty powder, and water is evenly prepared at a mass ratio of 1:1, the rest is the same as step (1) in Example 1;

[0068] (2) primer construction is identical with step (2) in embodiment 1;

[0069] (3) Construction of color difference adjustment material

[0070] Except that the formulas of silicone resin adjustment material, color correcting agent A, color correcting agent B, and color correcting agent C are different, the rest are the same as step (3) in Example 1;

[0071] Among them, the silicone resin adjustment material includes the following components in mass percentage: 32.3% of water, 30% of pure acrylic emulsion, 12% of silicone emulsion, 16% of natural stone powder, 8% of talcum powder, 0.4% of defoaming agent, preservative 0.4%, dispersant 0.2%, thickener 0.7%;

[0072] The silicone resin adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com