A kind of preparation method of chrome-free silane film before aluminum coil coating

A technology of chrome silane and aluminum coil, applied in the field of preparation of chrome-free silane film, can solve problems such as containing chromium, and achieve the effects of low use concentration, low environmental pollution and reliable treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

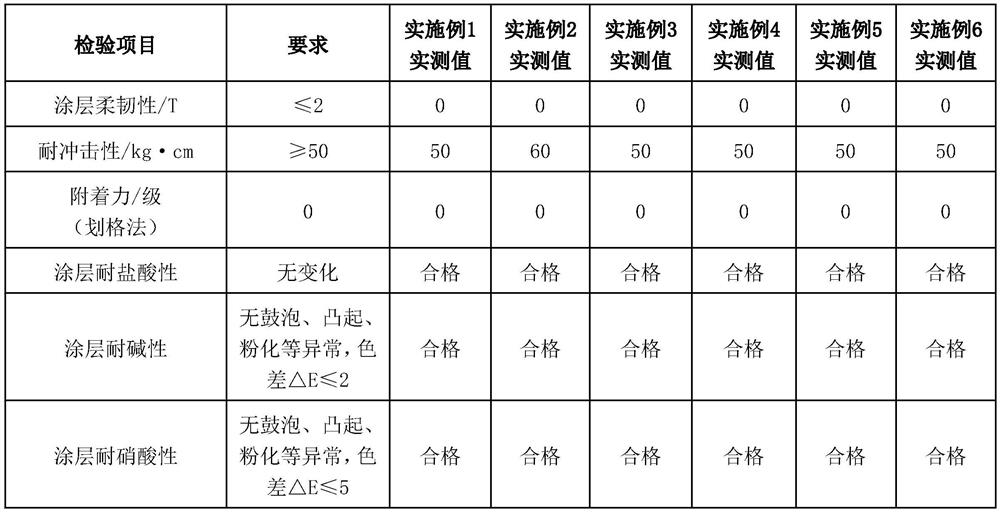

Examples

Embodiment Construction

[0034] In order to make the purpose of the present invention, technical solutions and advantages clearer, the present invention will be further described below in conjunction with Embodiment 1~6:

[0035] 1) Cleaning: Dip the aluminum coil in acid / alkaline cleaning solution at room temperature for 30-60 seconds.

[0036] 2) Water rinsing: immerse the workpiece cleaned in step 1) in water, wherein the water should keep overflowing, the pH=5-9, the temperature is normal temperature, and the time is 30-60 seconds.

[0037] 3) Deionized water washing: wash the workpiece treated in step 2) with deionized water, wherein the conductivity of the dripping water is <20 us / cm, the temperature is normal temperature, and the time is 10 seconds.

[0038] 4) Direct spray pure water washing: 10 seconds, normal temperature.

[0039] 5) Silane treatment: the silane treatment solution includes the following components by mass:

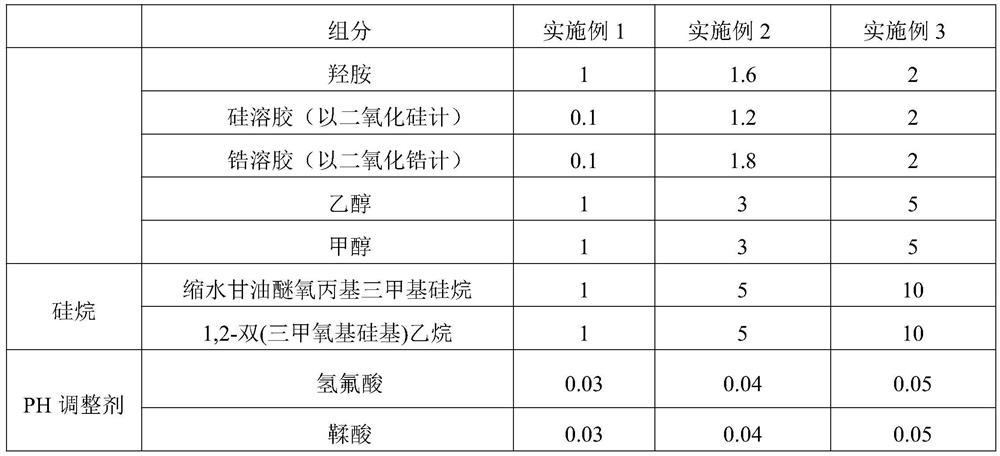

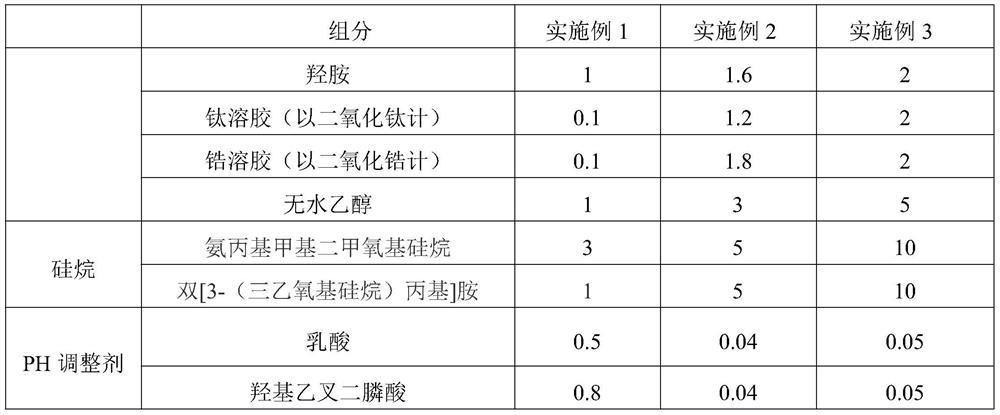

[0040] 2-20 parts of silane coupling agent,

[0041] 0-2 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com