Fruit grabbing manipulator and grabbing method thereof

A technology for grasping manipulators and fruits, which is applied in the field of fruit packaging, can solve problems such as skin bruises, and achieve the effects of flexible and accurate grasping, rapid displacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

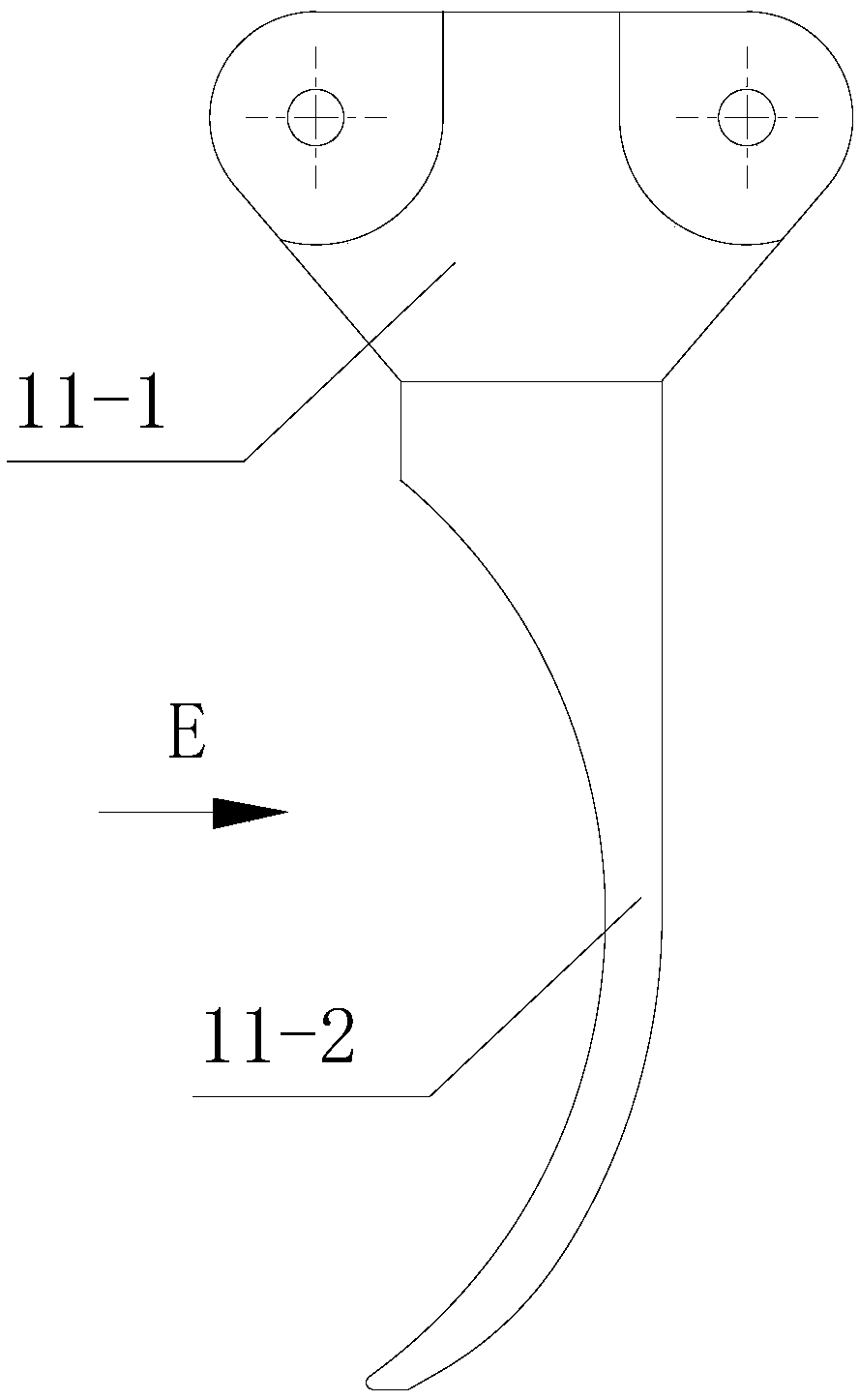

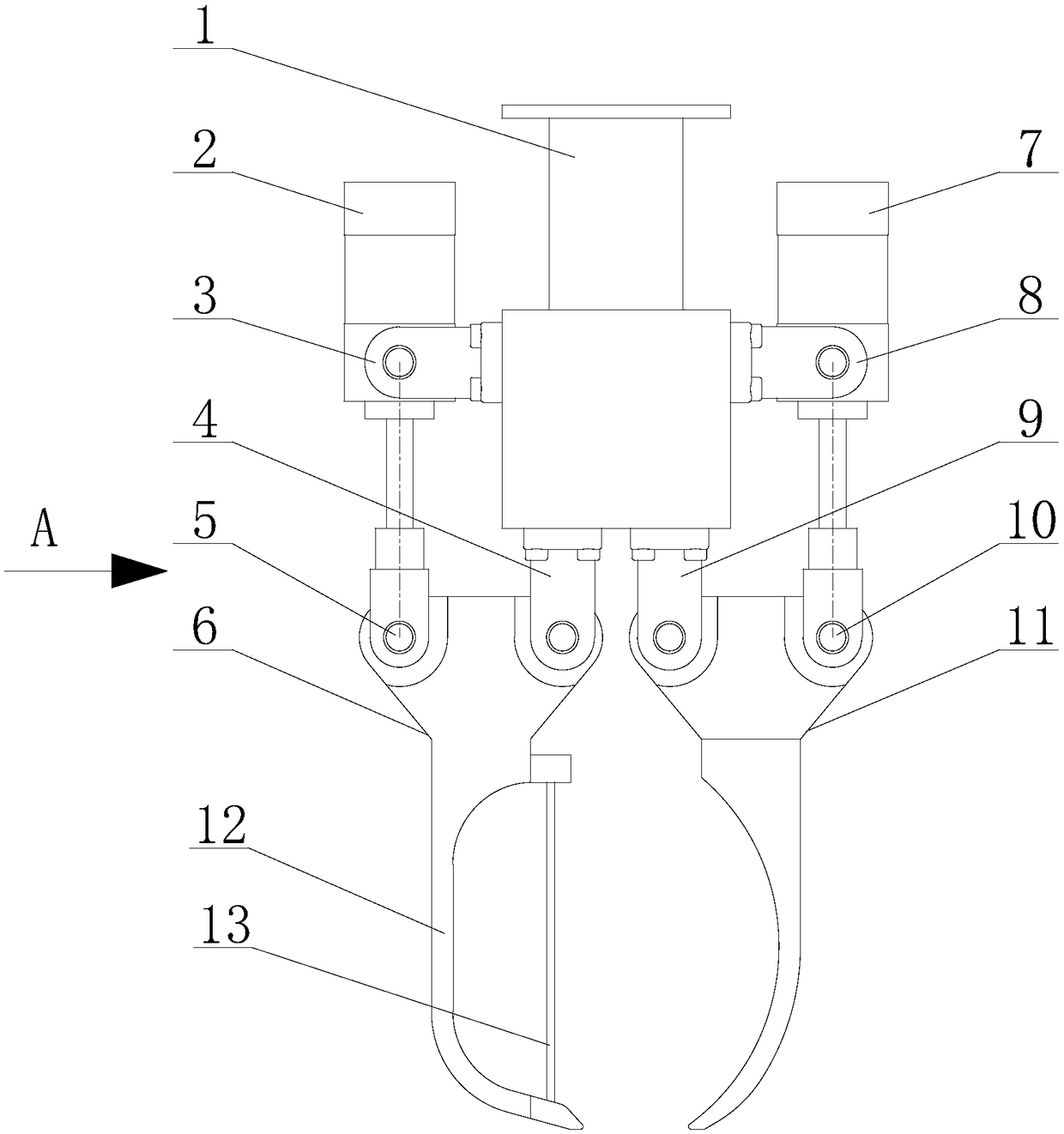

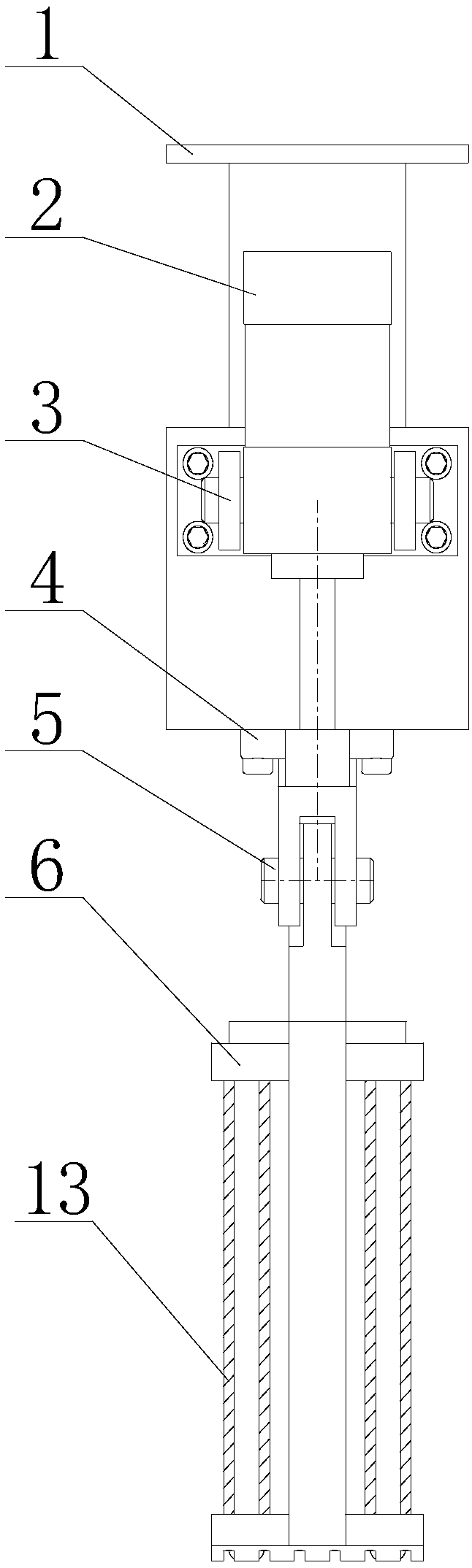

[0045] A kind of fruit grasping manipulator of present embodiment, as figure 1 or figure 2As shown, it includes a flexible jaw 6, a rigid jaw 11 and an opening and closing drive mechanism. The opening and closing drive mechanism includes a base 1, a first cylinder 2, a first cylinder seat 3, a first support 4, a first hinge support 5, The second cylinder 7, the second cylinder block 8, the second support 9 and the second hinge support 10; the first cylinder and the second cylinder are respectively installed on both sides of the base, and the bottom of the base is provided with the first support and the second support. Two supports, the first cylinder base and the second cylinder base are respectively arranged on both sides of the base, the first cylinder is fixedly installed on the base through the first cylinder base, and the second cylinder is fixedly installed on the base through the second cylinder base The end of the piston rod of the first cylinder is provided with a f...

Embodiment 2

[0052] This embodiment is the grabbing method of the fruit grabbing manipulator described in Example 1. After the fruit grabbing manipulator moves to the top of the fruit to be grabbed, the opening and closing driving mechanism drives the flexible gripper and the rigid gripper to open to both sides. After the fruit enters the fruit holding space, the opening and closing driving mechanism drives the flexible gripper and the rigid gripper. The jaws are retracted, and the fruit is flexibly clamped by the elastic force of the elastic string on the flexible jaws.

[0053] The whole of the fruit grabbing manipulator is externally connected to the wrist of the industrial robot through the top of the base, and is driven by the industrial robot to perform actions such as grabbing, moving, and letting go of the fruit. Such as Figure 11 As shown, the specific process is:

[0054] (1) The fruit grabbing manipulator is moved by the industrial robot above the fruit to be grabbed;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com