Friction welding axial deformation precision control process

A technology of friction welding and axial deformation, which is applied in the direction of welding equipment, manufacturing tools, non-electric welding equipment, etc., to achieve the effect of eliminating the deviation of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

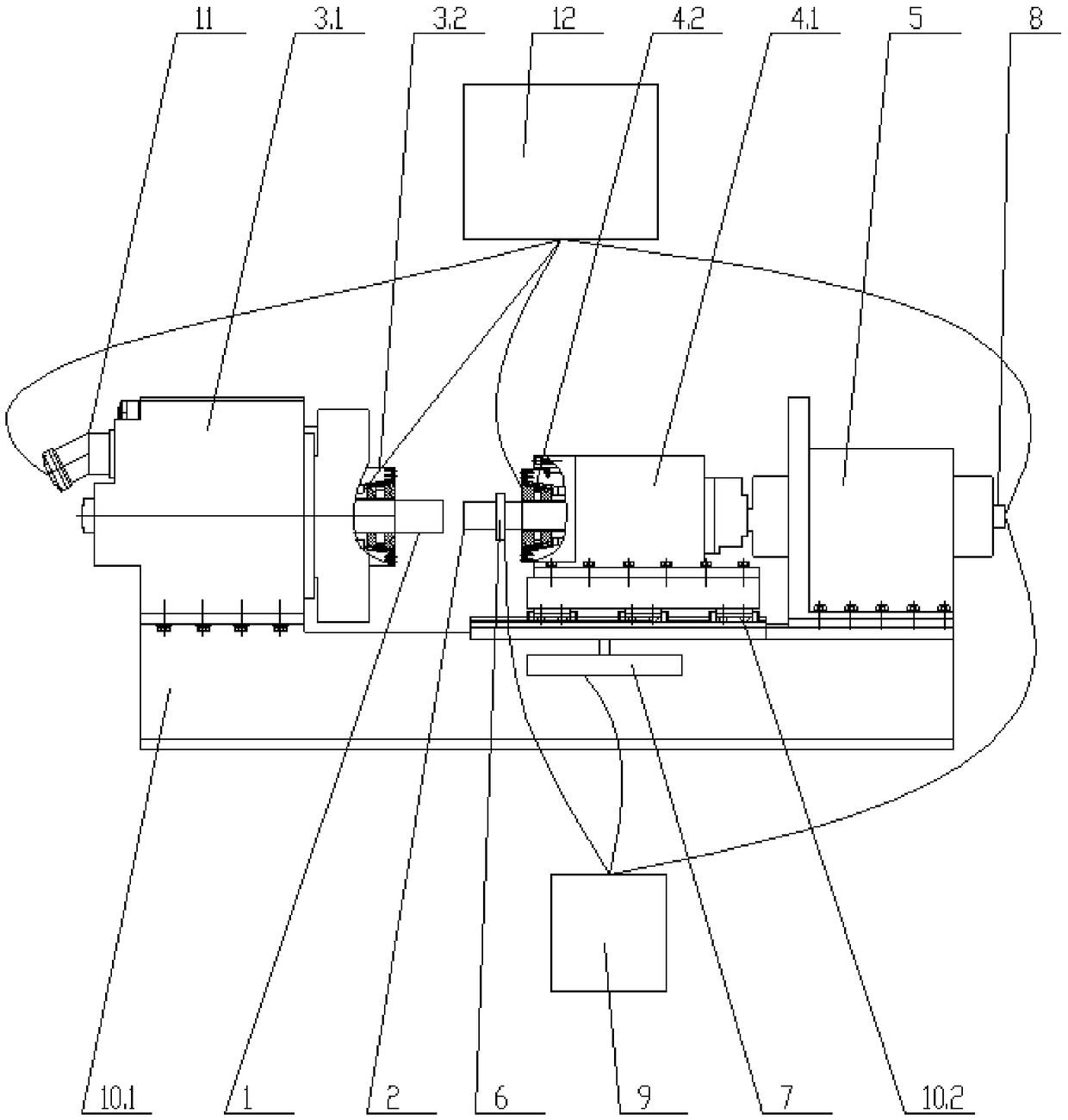

[0039] Such as figure 1 As shown, a friction welding axial deformation accuracy control process is characterized by:

[0040] (1) Automatic measurement of the axial dimensional accuracy of the rotating workpiece 1 and the moving workpiece 2: input the axial dimensions of the rotating workpiece 1 and the moving workpiece 2 of standard size into the friction welding control system 9, and the rotating workpiece 1 of the standard size is clamped in The rotating piece fixture 3.2, the moving workpiece 2 is clamped in the moving piece fixture 4.2, and the welding loading mechanism 5 pushes the moving slide system 4.1, the moving piece fixture 4.2 and the moving workpiece 2 to walk in the direction of the rotating workpiece 1 until the rotating workpiece 1 and the moving workpiece 2 close contact, the displacement sensor 7 records the position data after the close contact between the rotating workpiece 1 and the moving workpiece 2, and transmits the position data to the friction weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com