Composite jet flow micro-nano machining method and device

A technology of micro-nano processing and jet flow, which is applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problems of difficult processing, processing localization, processing accuracy and surface quality, and limited size, etc., to achieve Low manufacturing cost, improved processing localization, high efficiency and low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

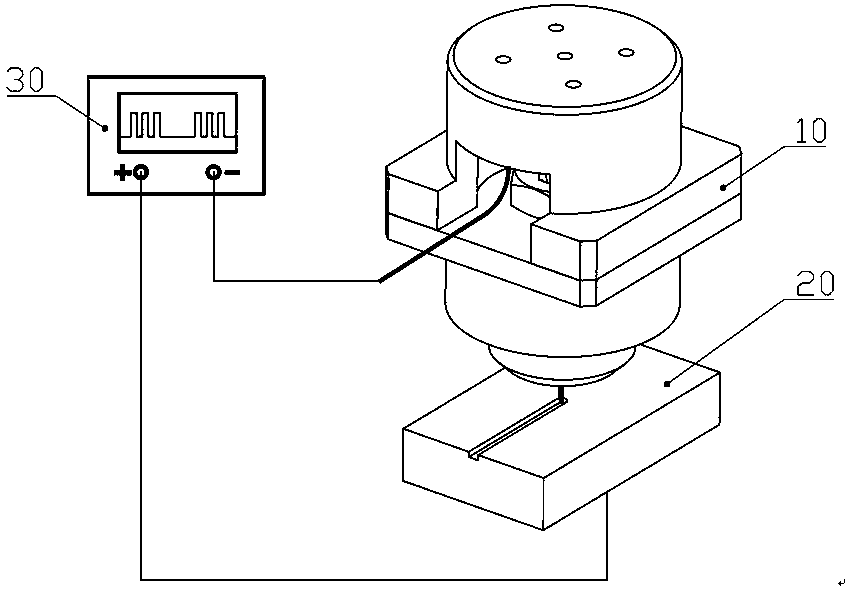

[0031] Such as figure 1 As shown, the composite jet micro-nano processing device of the present invention includes a multi-constraint composite nozzle 10, a workpiece anode 20 and a narrow pulse width group pulse electrolysis power supply 30;

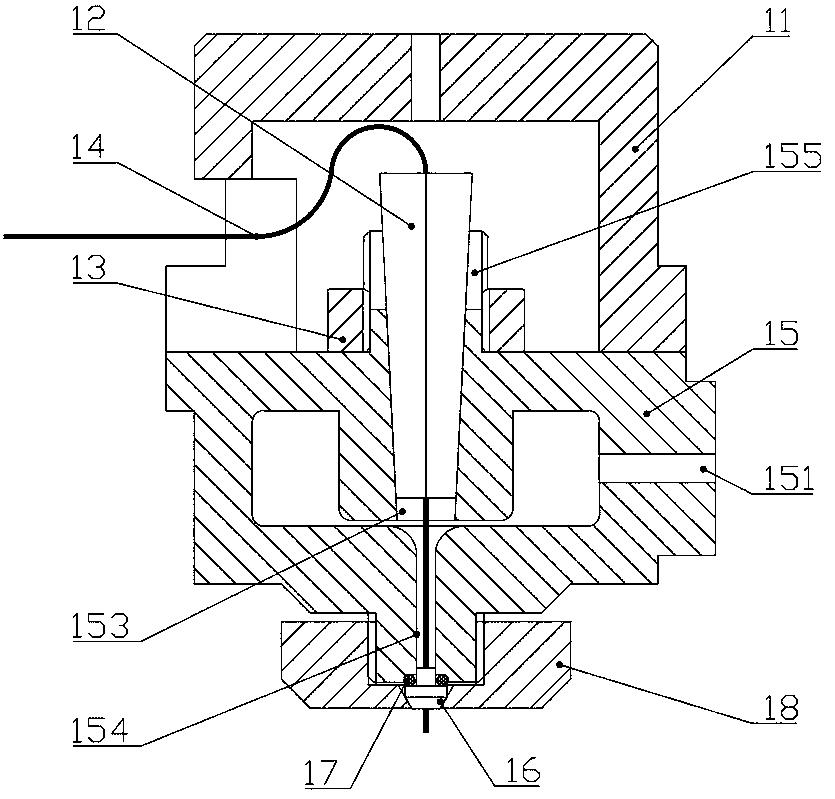

[0032] Such as figure 2 , 3 As shown, the multi-constraint composite nozzle 10 includes an upper cover plate 11, a rubber plug 12, a lock nut 13, an electrode wire 14, a cavity 15, a nozzle 16, an O-ring 17 and a nozzle fixing sleeve 18;

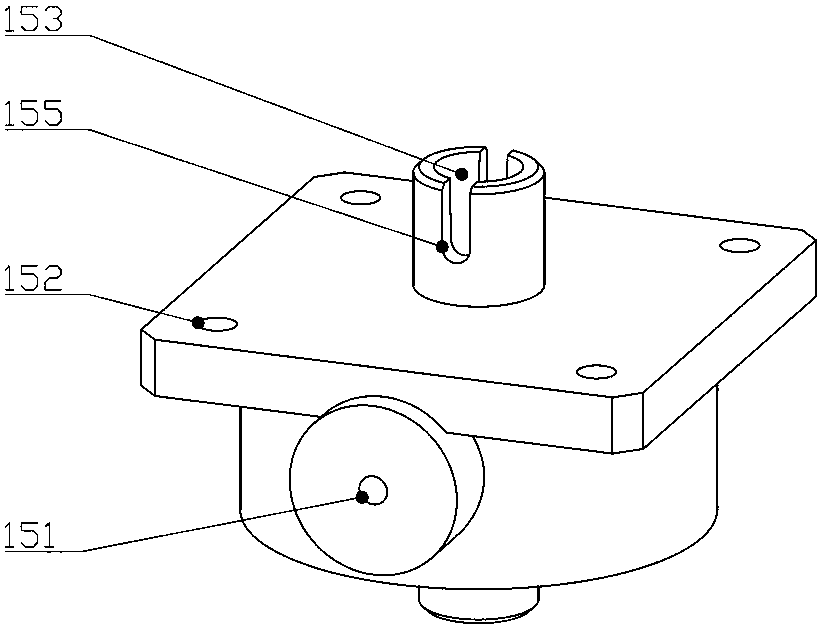

[0033] The cavity 15 is an entity with a cavity inside. The upper part of the cavity 15 has an end face fitted with the upper cover plate 11. The end face is provided with a connecting hole 152. The cavity 15 is connected to the upper cover plate 11 through the connecting hole 152. threaded connection; the side wall of the cavity 15 has an electrolyte inlet hole 151, and the center of the bottom of the cavity 15 has a slender electrolyte outlet flow channel 154; the central axis of the cavity 15 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com