A new energy biomass fuel preparation process

A biomass fuel and preparation technology, applied in the direction of waste fuel, fuel, solid fuel, etc., can solve the problems of low crushing efficiency, screen blockage, easy sticking of biomass, etc., to prevent insufficient crushing, prevent crushing dead ends, The effect of speeding up the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

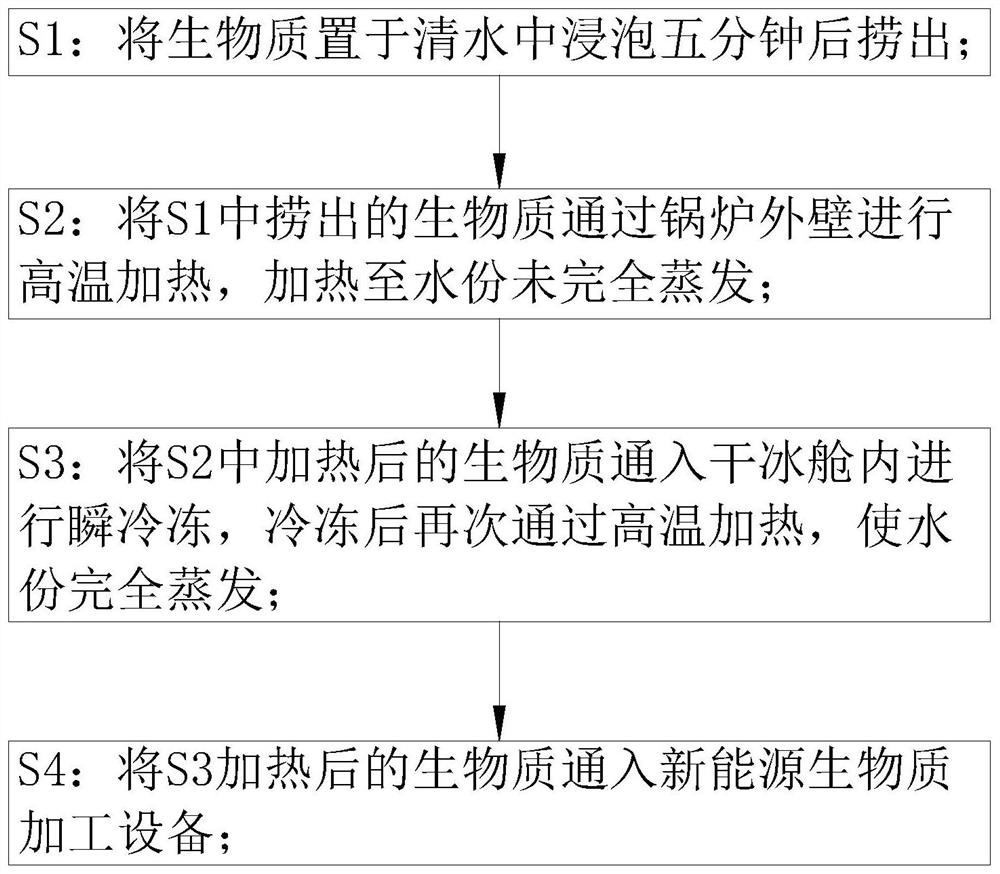

Method used

Image

Examples

Embodiment approach

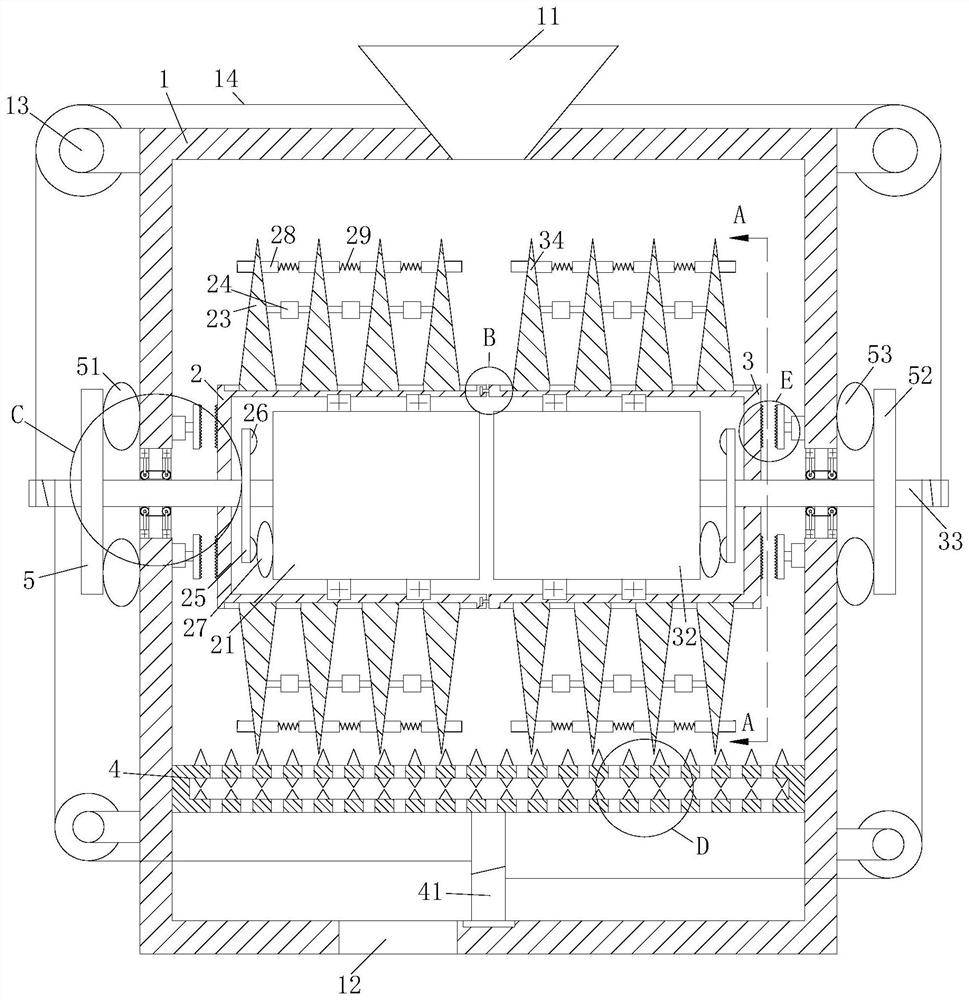

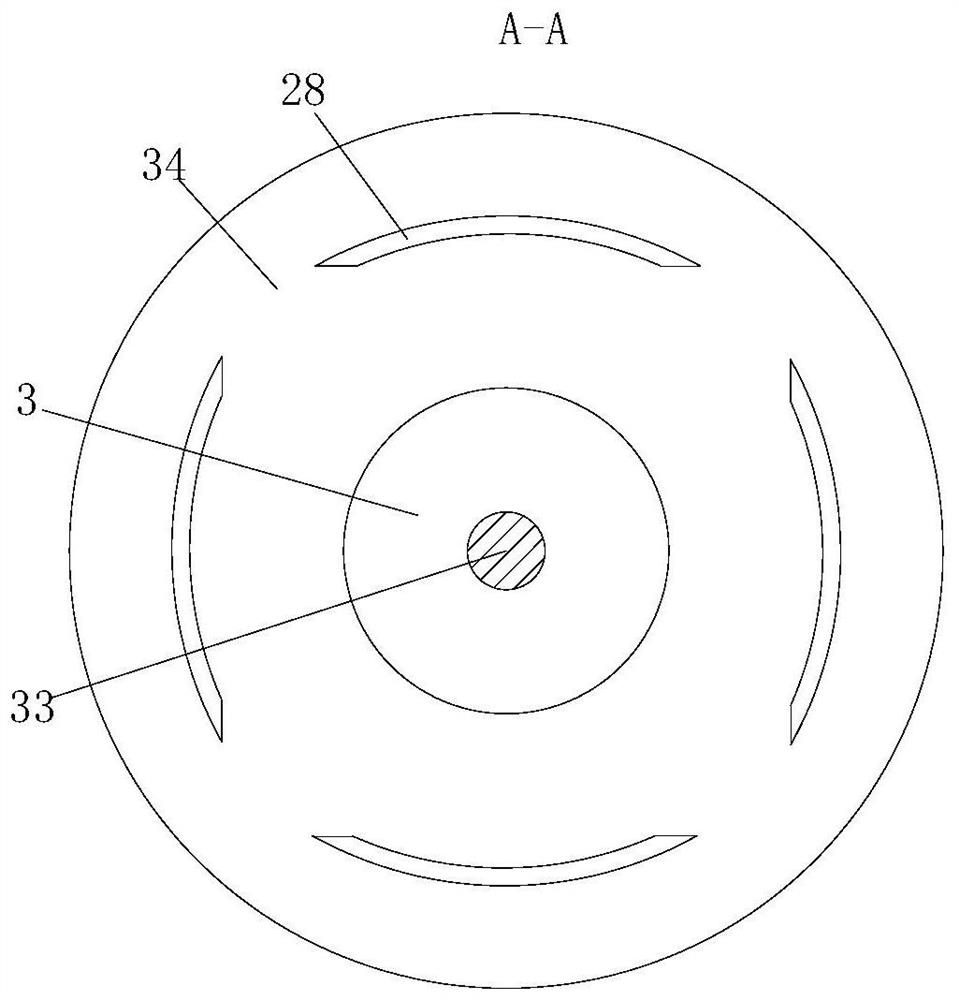

[0041] As an embodiment of the present invention, the rotating shaft of the motor 21 and the first rotating shaft 33 are both fixedly connected to the frame body 1 through two bearings, and two fixing rods 15 are fixedly connected to the inner walls of the bearings; Both runners 16 are rotatably connected, and the surfaces of the two runners 16 are jointly sleeved with a belt 17, and the belt 17 is arranged close to the surface of the first rotating shaft 33 or the rotating shaft of the motor 21; when in use, the belt 17 and the bearing can be set to make the first The first rotating shaft 33 and the rotating shaft of the motor 21 can move left and right while rotating, so as to increase the distance that the first crushing ring 23 and the second crushing ring 34 move left and right, increase the crushing area, and effectively prevent the dead angle of crushing. The belt 17 can effectively reduce the frictional force and make The first rotating shaft 33 and the rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com