Dimensional constraints for three-dimensional batteries

A technology of restraints and secondary batteries, which is applied to lithium batteries, battery electrodes, secondary batteries, etc., and can solve problems such as battery failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

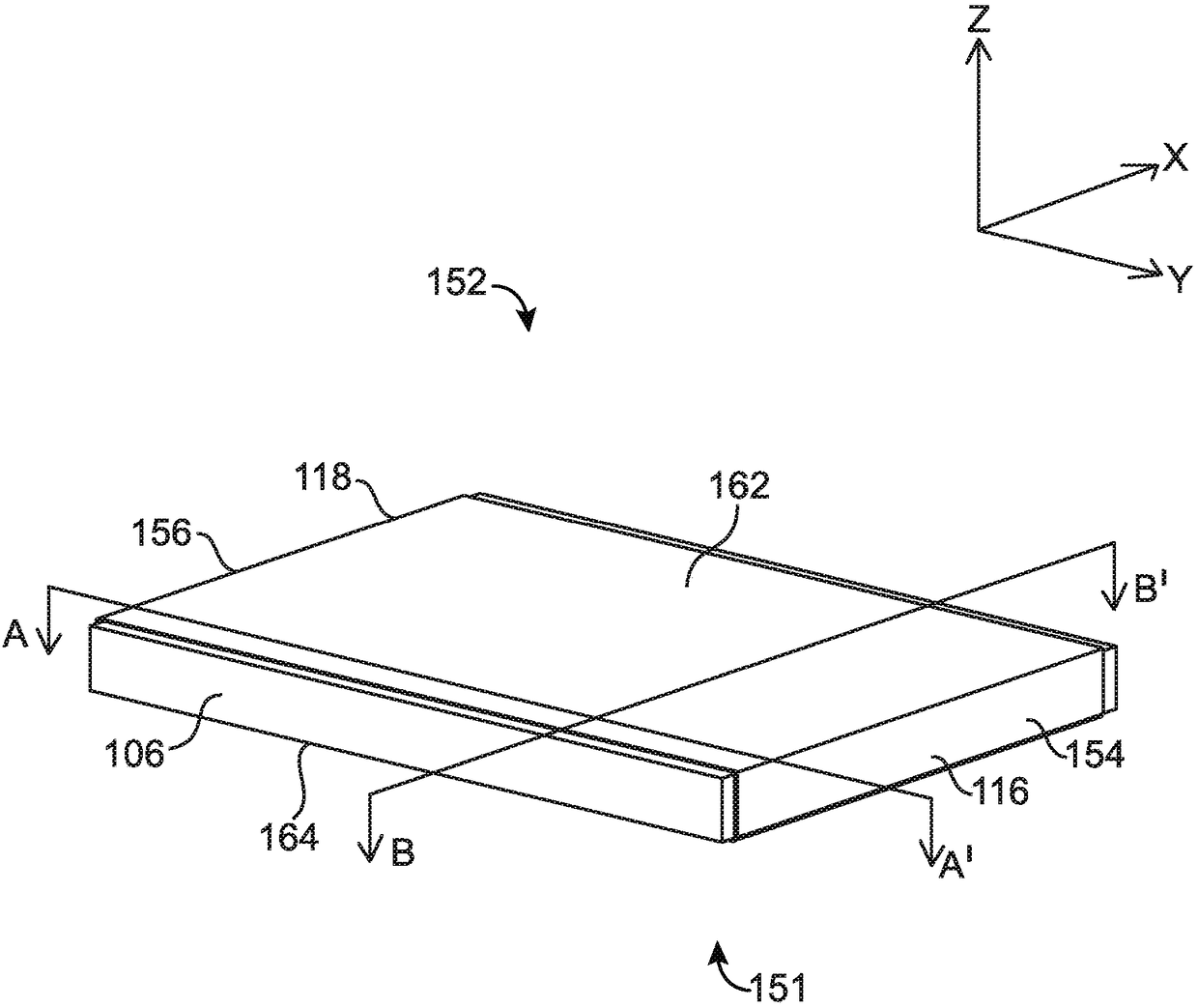

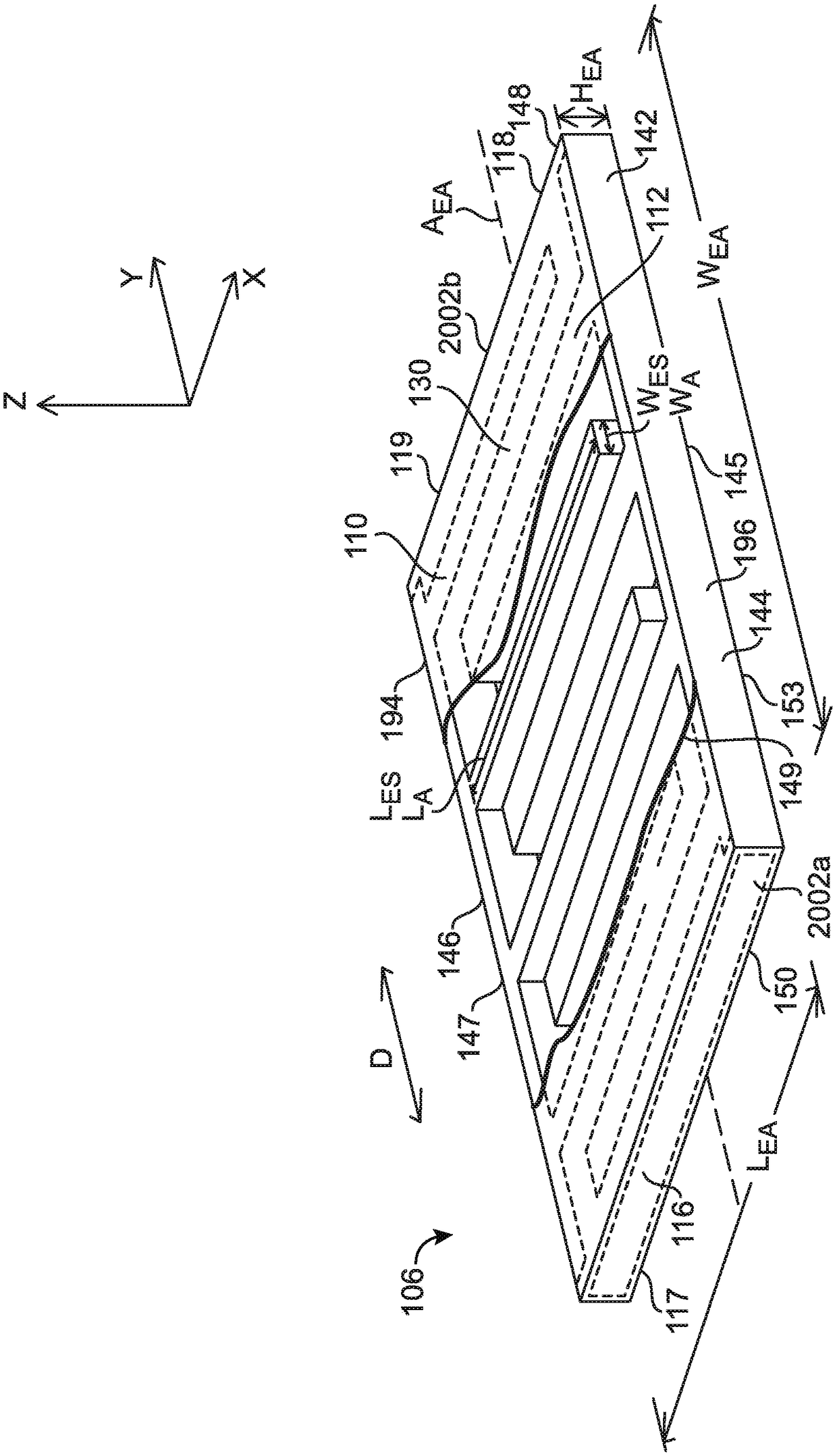

[0329] This example illustrates an example of a method of manufacturing an electrode assembly 106 having a set of constraints 108 . here will Figure 21 called an example of the method.

[0330] In this example, in step S1, the anode and cathode stems 134, 141, respectively, are fabricated. Then, as shown in step S2 , the anode 110 is fabricated by forming an anode active material 132 (eg, silicon-containing material) on the anode stem 134 . In step S3, the anode and cathode current collectors 136, 140 are fabricated, respectively. As shown in step S4, a set of restraints 108 is manufactured. In step S5 , a material for forming the separator 130 is deposited on the side of the anode current collector 136 . In step S6 , cathode active material 138 is formed by depositing material between anode structure 110 and cathode stem 141 . Finally, in step S7, the electrode assembly 106 is connected to the tab, packaged, filled with electrolyte and sealed. According to one embodime...

Embodiment 1

[0332] Embodiment 1. A secondary battery that circulates between a charged state and a discharged state, the secondary battery includes a battery case, an electrode assembly located in the battery case, carrier ions, a non-aqueous liquid electrolyte, and a set of electrode constraints, where

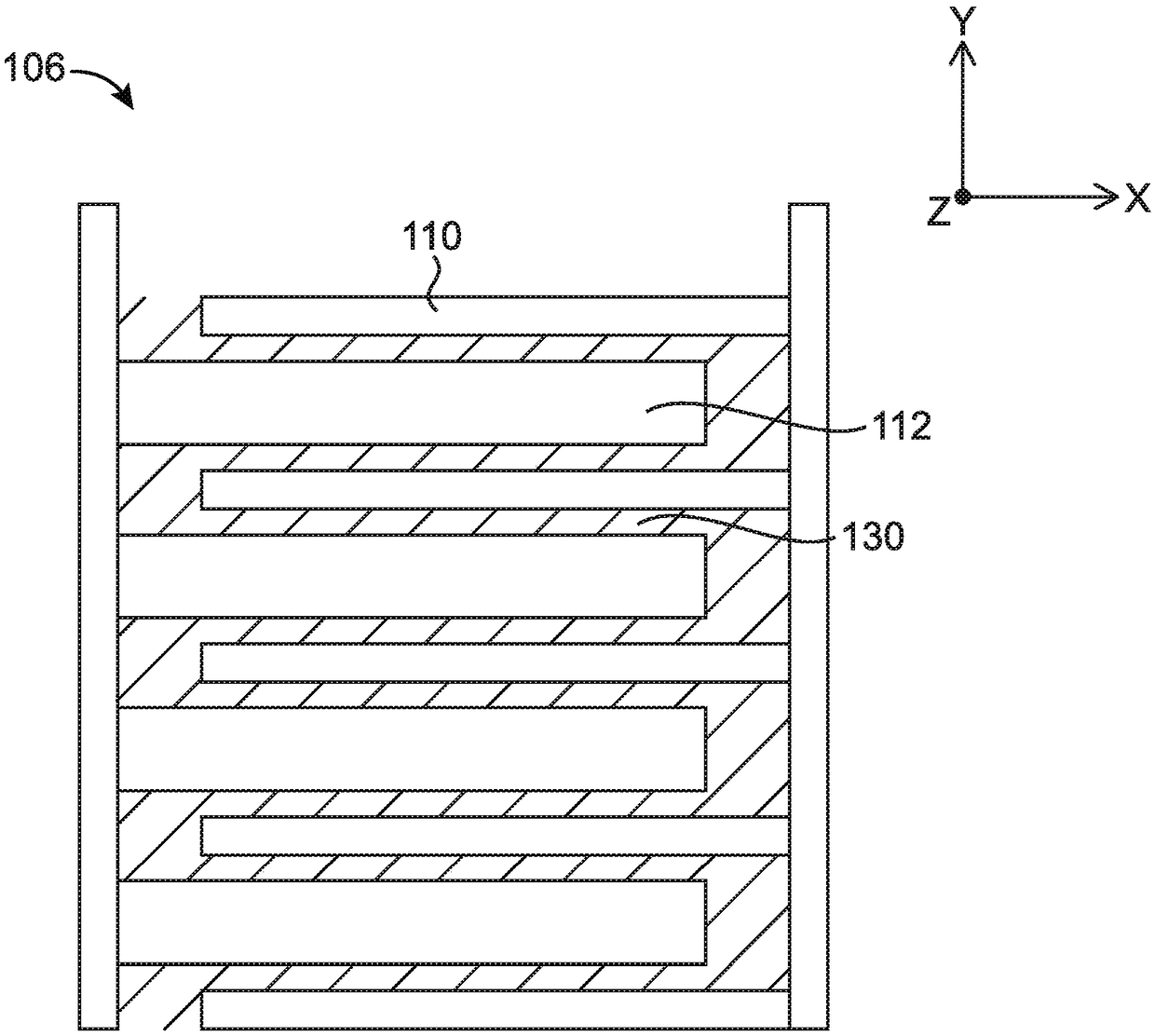

[0333] The electrode assembly has a longitudinal axis, a transverse axis, and a vertical axis perpendicular to each other, a first longitudinal end surface and a second longitudinal end surface separated from each other in the longitudinal direction, and a longitudinal axis A surrounding the electrode assembly. EA and connecting the first longitudinal end surface and the transverse surface of the second longitudinal end surface, the transverse surface has a spacer on opposite sides of the longitudinal axis and separated in a first direction orthogonal to the longitudinal axis. Relative to the first region and the second region, the electrode assembly has a maximum width W measured in the...

Embodiment 2

[0338] Embodiment 2. The secondary battery of embodiment 1, wherein the primary confinement array constrains growth of the electrode assembly in the longitudinal direction such that during 30 consecutive cycles of the secondary battery, the Any increase in the Feret diameter of the electrode assembly in the longitudinal direction is less than 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com