Fuel cell bipolar plate with interrupt structure

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, battery electrodes, structural parts, etc., can solve the problems of MEA film damage, battery failure, and no prevention of cooling water bypass flow, etc., to improve durability and The effect of stability and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

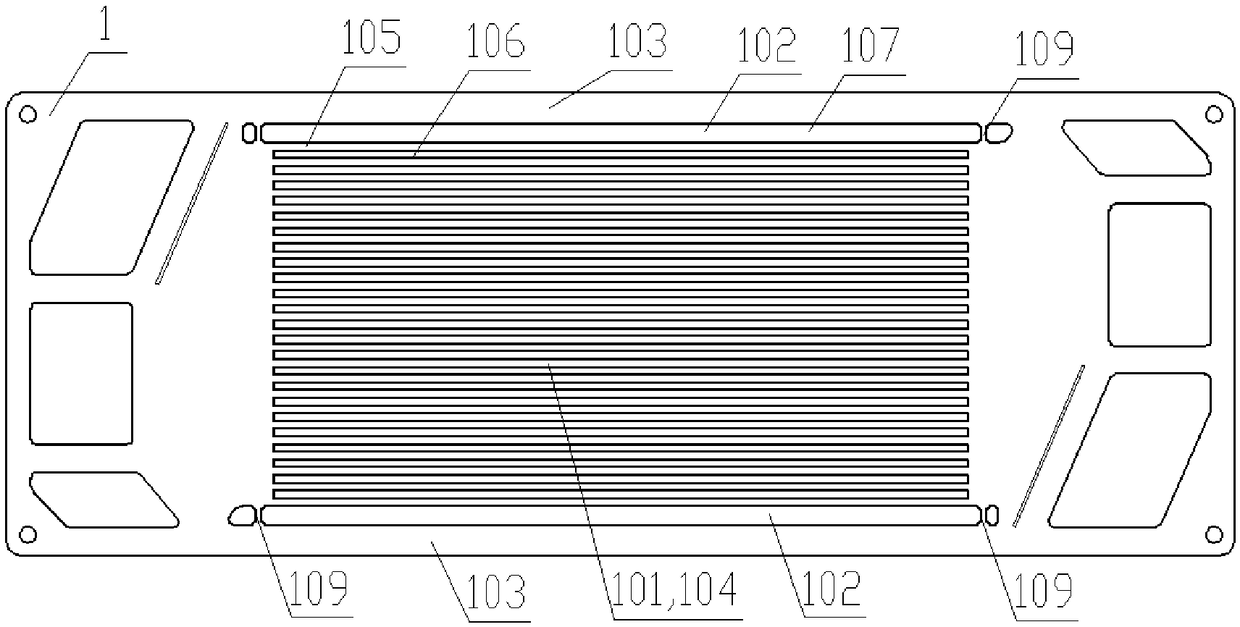

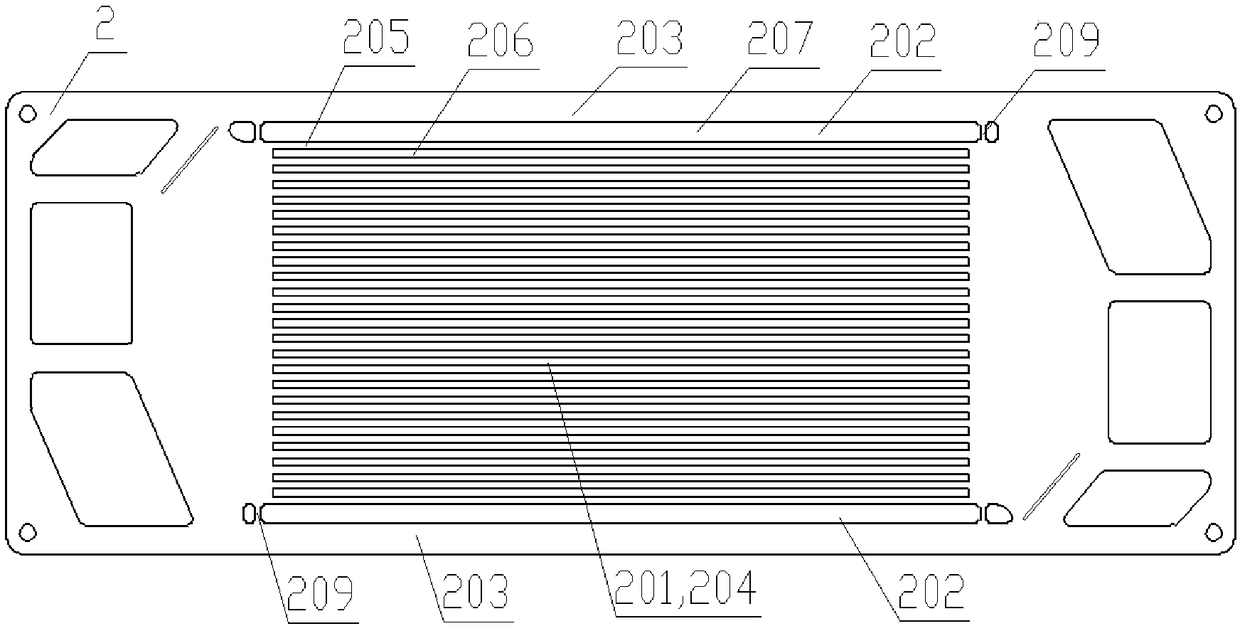

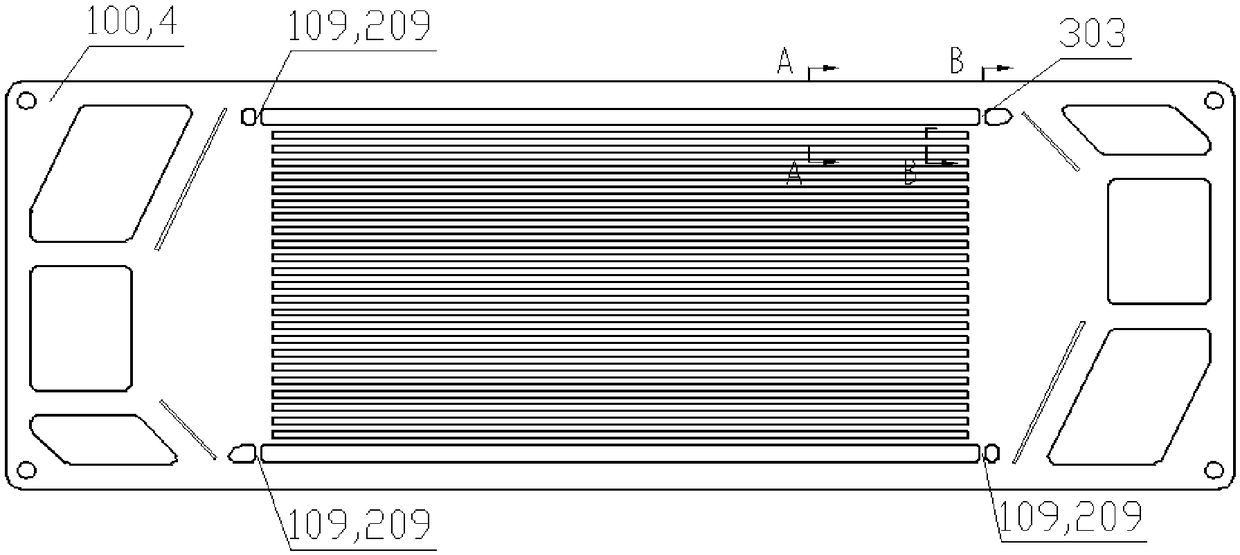

[0025] Such as Figure 1 to Figure 5As shown, the bipolar plate 100 includes a cathode plate 1 and an anode plate 2, the space between the cathode plate 1 and the anode plate 2 forms a cooling water flow field, and the space between the cathode plate 1 and the anode plate 2 and the membrane electrode 4 are respectively The cathode flow field and the anode flow field are formed; the centerlines of each flow channel in the active area of the cathode plate 1 and the anode plate 2 are aligned, the flow channel is a flat flow channel, and the isolation area is 0.04mm higher than the ridge of the active area flow channel. The cooling water discontinuity structure 303 includes the groove 109 on the cathode isolation area and the groove 209 on the anode isolation area corresponding to the groove 109 on the cathode isolation area on the anode plate isolation area, respectively formed in the cooling water cavity Boss, four grooves 109 on the cathode isolation area, four grooves 209 on...

Embodiment 2

[0027] The structure of the second embodiment is the same as that of the first embodiment, only the flow channel in the active area is a corrugated flow channel with different corrugation directions. Such as Figure 6 ~ Figure 8 As shown, the bipolar plate 100 includes a cathode plate 1 and an anode plate 2, the space between the cathode plate 1 and the anode plate 2 forms a cooling water flow field, and the other side of the cathode plate 1 and the anode plate 2 is attached to the membrane electrode 4; The flow channels of the cathode plate 1 and the anode plate 2 are corrugated flow channels, and the centerlines of each flow channel in the active area are not aligned; there are four bosses 107 on the cathode isolation area of the cathode plate 1, and the protrusions on the cathode isolation area are four. 107 is 0.04mm higher than the ridge of the cathode flow channel, its length is 2mm, and its width is 4mm; there are eight bosses 301 on the edge flow channel ditch of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com