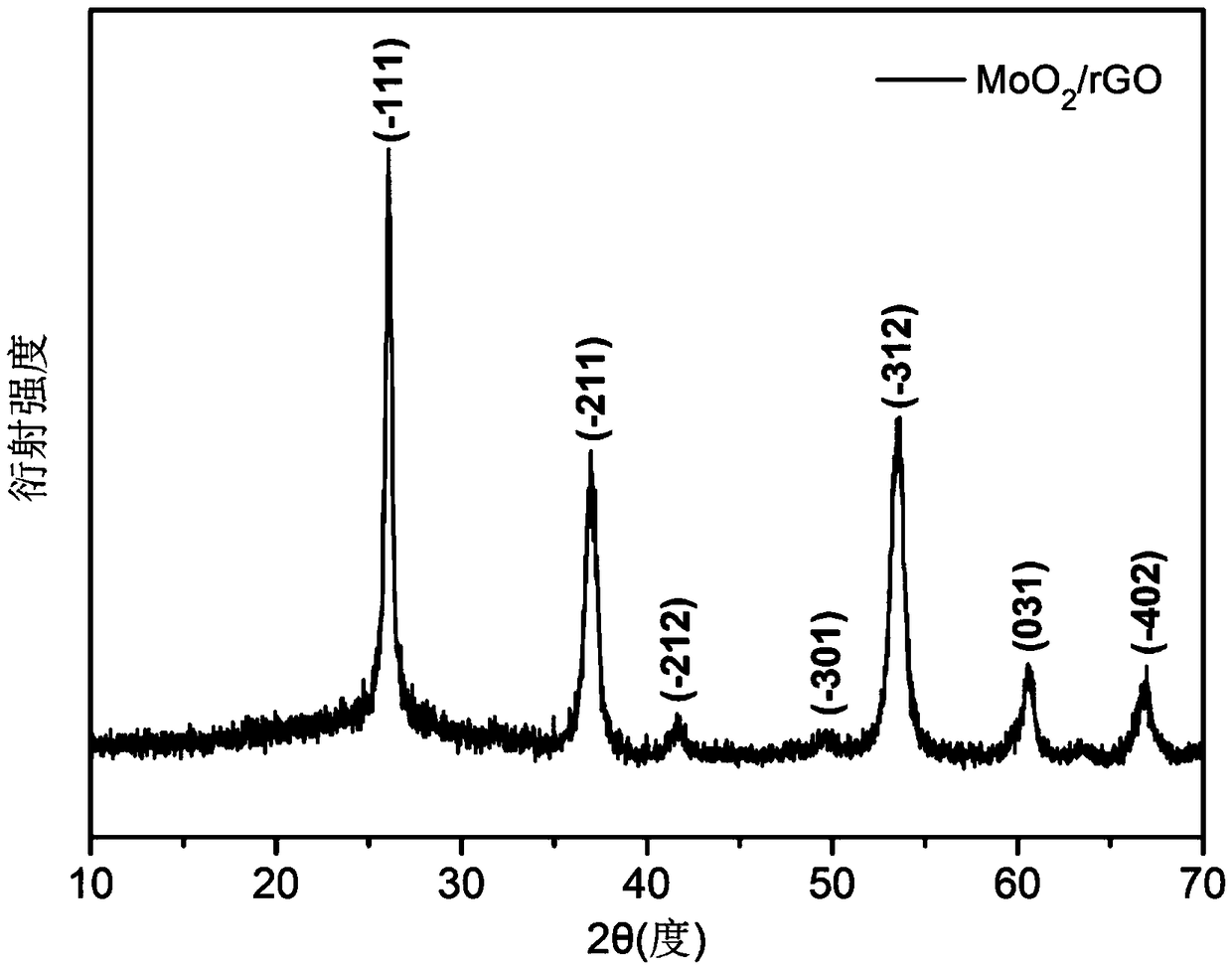

MoO2/rGO composite material, and preparation method and application thereof

A composite material and mixed solution technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of harsh preparation conditions and cumbersome preparation methods, and achieve the effects of low cost, increased specific capacity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

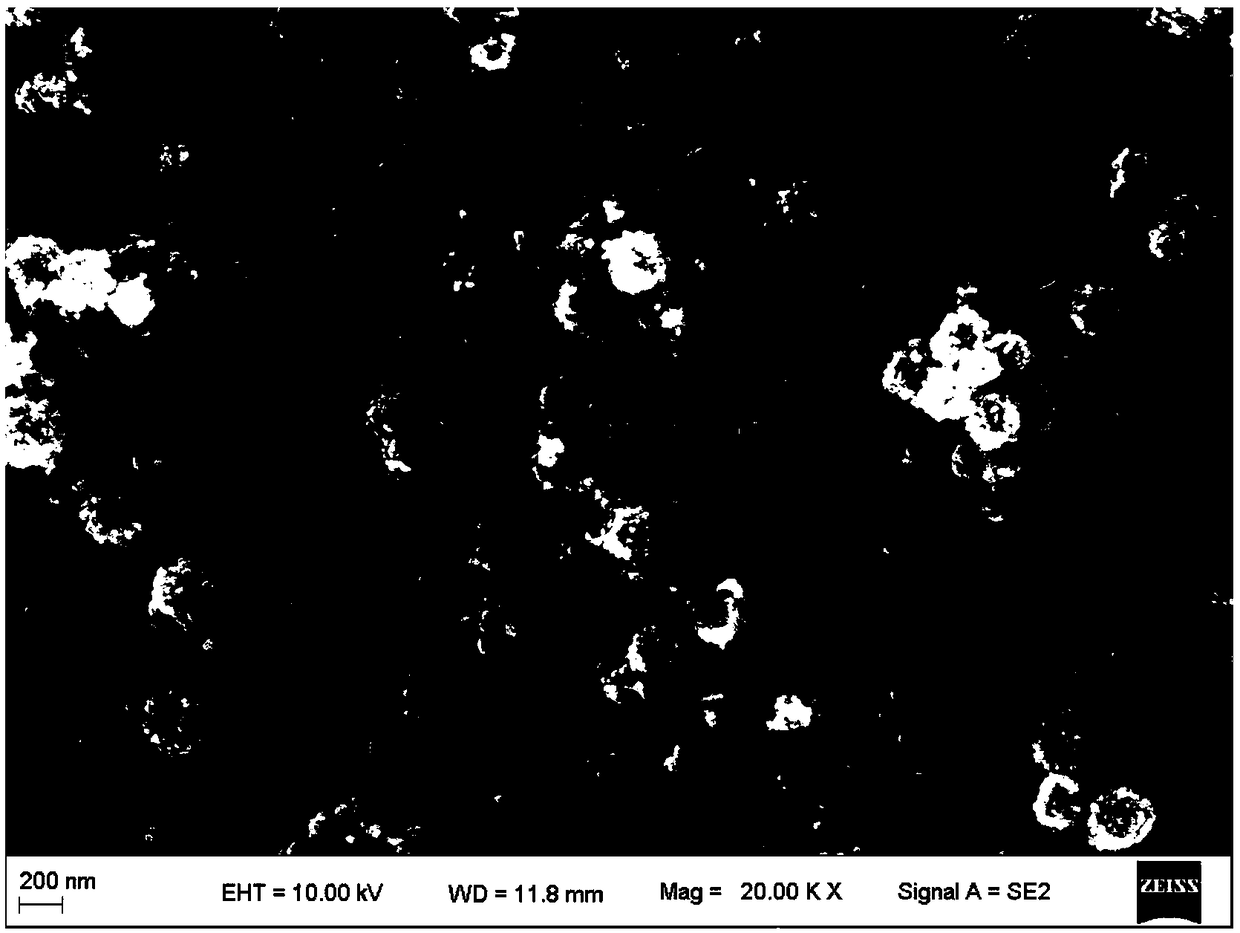

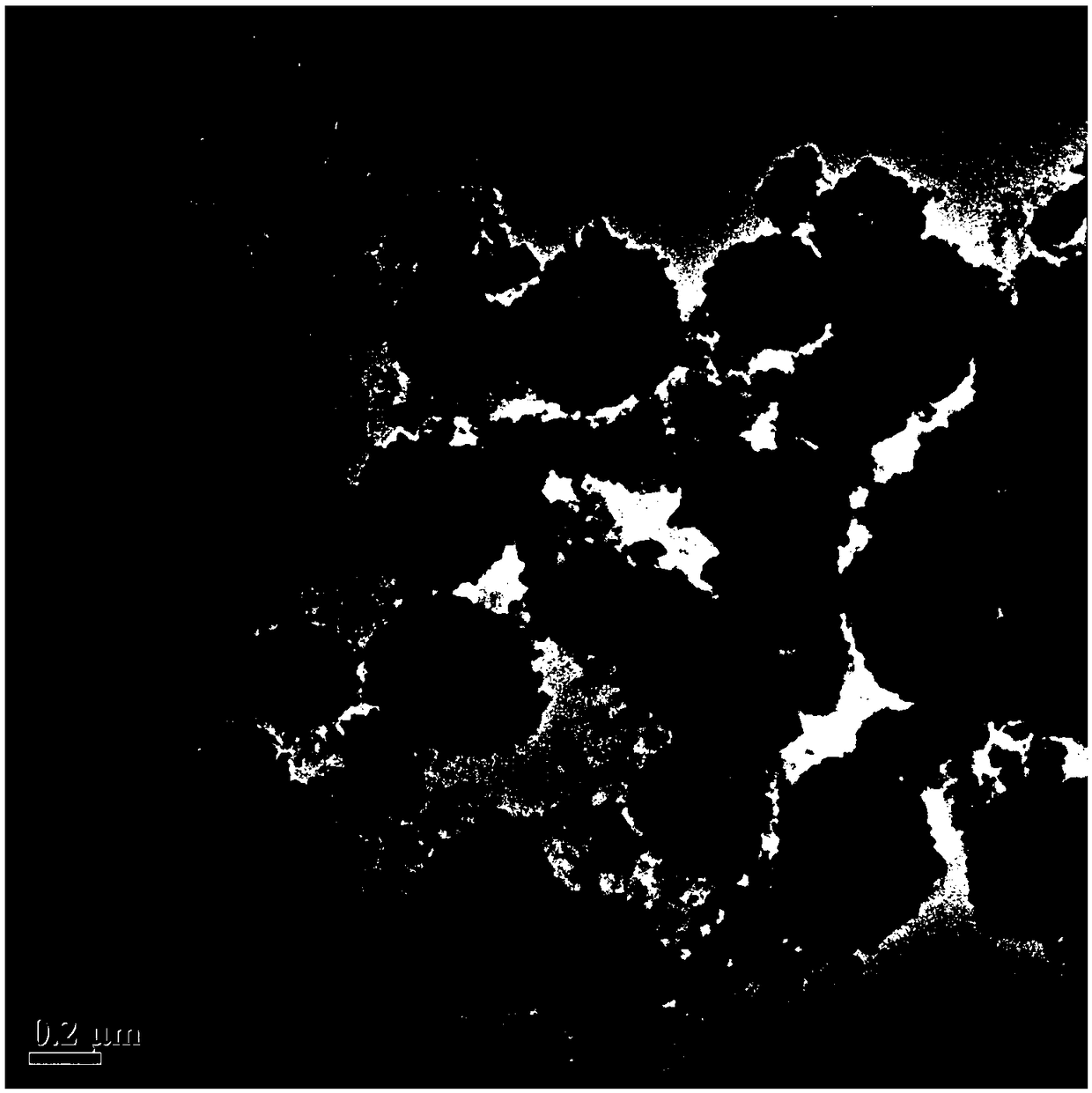

[0058] A kind of MoO 2 The preparation method of / rGO composite material, comprises the following steps:

[0059] (1) Dissolve 80 mg of graphene oxide (GO) in 30 mL of deionized water, and ultrasonicate for 1 h to obtain a well-dispersed GO solution. Add concentrated HCl dropwise to adjust the pH value to 2, and then add 0.8 g of ammonium molybdate tetrahydrate and 0.0798 g ascorbic acid, magnetically stirred for 15min until it was completely dissolved;

[0060] (2) Transfer the mixed solution obtained in step (1) into a 50mL Teflon-lined stainless steel autoclave, and conduct a hydrothermal reaction at 180°C for 15h to obtain MoO 2 / rGO composite precursor;

[0061] (3) After hydrothermal cooling to room temperature, the obtained MoO 2 / rGO composite precursor was centrifuged, fully washed with deionized water and alcohol until neutral, dried in a vacuum oven at 60 °C for 12 h, and heated to 400 °C at a heating rate of 1 °C / min under the protection of argon, and calcined fo...

Embodiment 2

[0068] A kind of MoO 2 The preparation method of / rGO composite material, comprises the following steps:

[0069] (1) Dissolve 100 mg of graphene oxide (GO) in 30 mL of deionized water, ultrasonicate for 2 hours to obtain a GO solution with good dispersion, add concentrated HCl dropwise to adjust the pH value to 1.5, add 0.8 g of ammonium molybdate tetrahydrate and 0.4560 g ascorbic acid, magnetically stirred for 30min, until it was completely dissolved;

[0070] (2) Transfer the mixed solution obtained in step (1) into a 50mL Teflon-lined stainless steel autoclave, and conduct a hydrothermal reaction at 200°C for 10h to obtain MoO 2 / rGO composite precursor;

[0071] (3) After hydrothermal cooling to room temperature, the obtained MoO 2 / rGO composite precursor was centrifuged, fully washed with deionized water and alcohol until neutral, dried in a 50°C blast drying oven for 12h, and heated to 500°C at a heating rate of 3°C / min under nitrogen protection, and calcined for 3h...

Embodiment 3

[0073] A kind of MoO 2 The preparation method of / rGO composite material, comprises the following steps:

[0074] (1) Dissolve 160mg of graphene oxide (GO) in 30mL of deionized water, ultrasonicate for 1.5h to obtain a GO solution with good dispersion, add concentrated HCl dropwise to adjust the pH value to 3, add 0.8g of ammonium molybdate tetrahydrate and 0.7980g ascorbic acid, magnetically stirred for 20min until it was completely dissolved;

[0075] (2) Transfer the mixed solution obtained in step (1) into a 50mL Teflon-lined stainless steel autoclave, and conduct a hydrothermal reaction at 220°C for 12h to obtain MoO 2 / rGO composite precursor;

[0076] (3) After hydrothermal cooling to room temperature, the obtained MoO 2 / rGO composite precursor was centrifuged, fully washed with deionized water and alcohol until neutral, dried in a vacuum oven at 100 °C for 12 h, and heated to 400 °C at a heating rate of 5 °C / min under the protection of argon, and calcined for 5 h , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com