High-performance photoelectric chemical water decomposition photoanode based on BiFeO3 ferroelectric effect, and preparation method thereof

A ferroelectric effect, high-performance technology, applied in the field of high-performance photoelectrochemical decomposition of water photoanode and its preparation, can solve the problems of wide bandwidth and low photoelectric conversion efficiency, achieve simple structure, improve photoelectrochemical performance, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

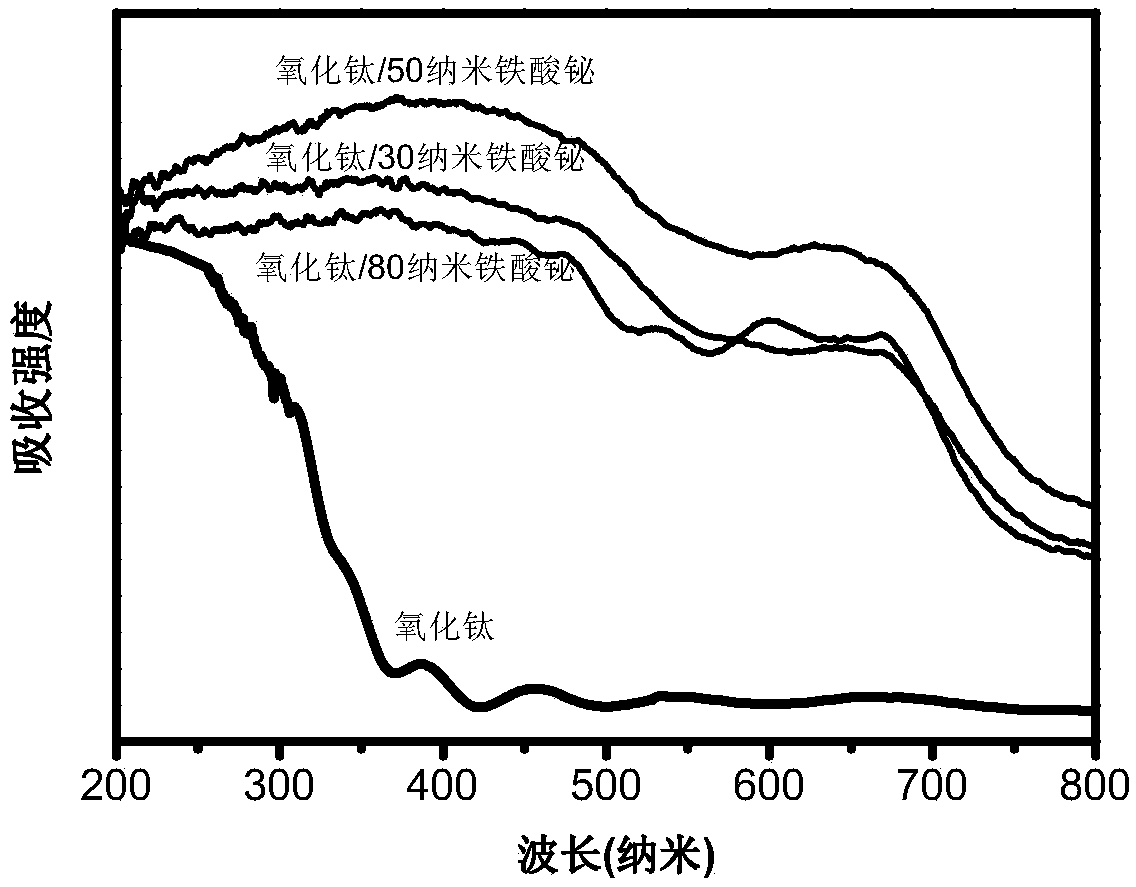

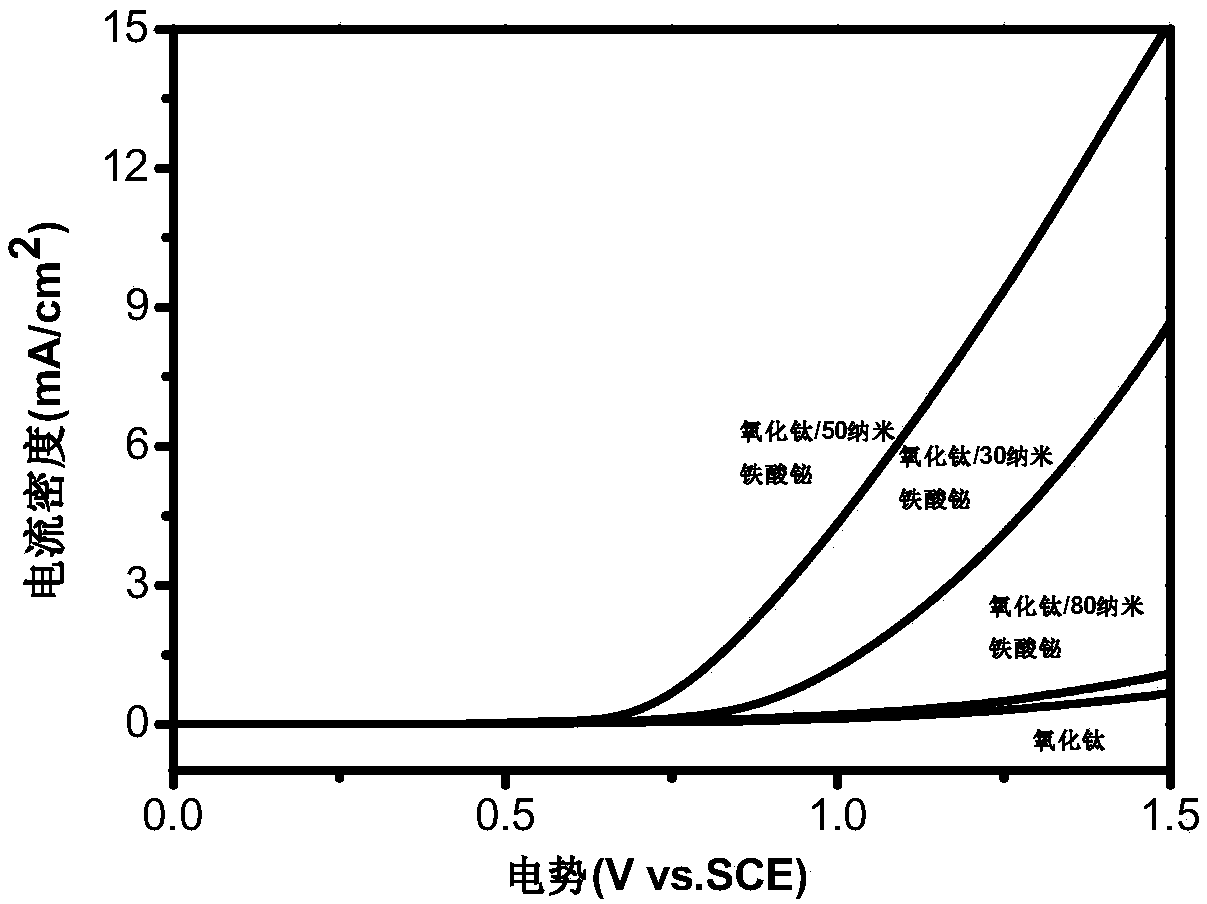

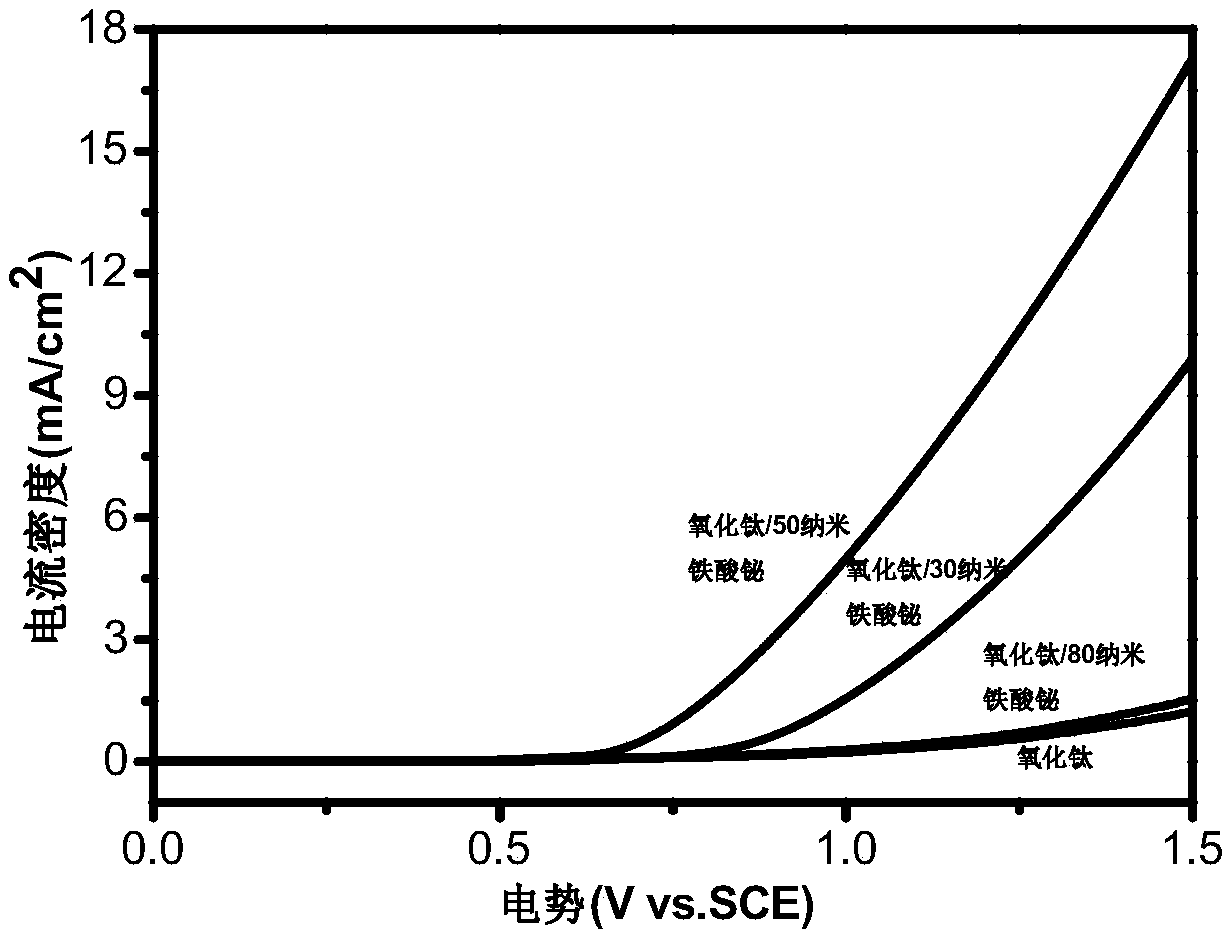

[0018] Example 1: TiO 2 Film thickness 30nm, BiFeO 3 The thickness of the film is 30nm, and it is used as a photoanode after packaging, a saturated calomel electrode as a reference electrode, a Pt sheet as a counter electrode, and an electrolyte solution of 1M NaOH aqueous solution. Depend on figure 1 It can be seen that compared with pure TiO 2 ,TiO 2 / 30nmBiFeO 3 The light absorption performance of the composite photoanode in the visible region is significantly enhanced. Depend on figure 2 and image 3 It can be seen that the photocurrent density under visible light and AM1.5G increases significantly.

Embodiment 2

[0019] Example 2: TiO 2 Film thickness 30nm, BiFeO 3 The thickness of the film is 50nm, and it is used as a photoanode after packaging, a saturated calomel electrode as a reference electrode, a Pt sheet as a counter electrode, and an electrolyte solution of 1M NaOH aqueous solution. The ferroelectric polarization effect is achieved by applying a forward and reverse voltage of 5V. Forwardly polarized BiFeO 3 The film is connected to the positive pole of the power supply, FTO is connected to the negative pole of the power supply, and BiFeO is used for reverse polarization 3 The film is connected to the negative pole of the power supply, and the FTO is connected to the positive pole of the power supply. Depend on figure 1 It can be seen that compared with pure TiO 2 ,TiO 2 / 50nmBiFeO 3 The light absorption performance of the composite photoanode in the visible region is significantly enhanced. At the same time, by figure 2 and image 3 It can be seen that the photocurr...

Embodiment 3

[0020] Example 3: TiO 2 Film thickness 30nm, BiFeO 3The thickness of the film is 80nm, and it is used as a photoanode after packaging, a saturated calomel electrode as a reference electrode, a Pt sheet as a counter electrode, and an electrolyte solution of 1M NaOH aqueous solution. Depend on figure 1 It can be seen that compared with pure TiO 2 ,TiO 2 / 80nmBiFeO 3 The light absorption performance of the composite photoanode in the visible region is significantly enhanced. At the same time, by figure 2 and image 3 It can be seen that the photocurrent density under visible light and AM1.5G has increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com