Leakage detecting device for ordinary pressure detection of vacuum sampling

A normal pressure and vacuum technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of affecting the repeatability and accuracy of test results, reducing the pressure range of vacuum box, low reliability, etc. Large detection accuracy level, simple structure, and the effect of improving cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

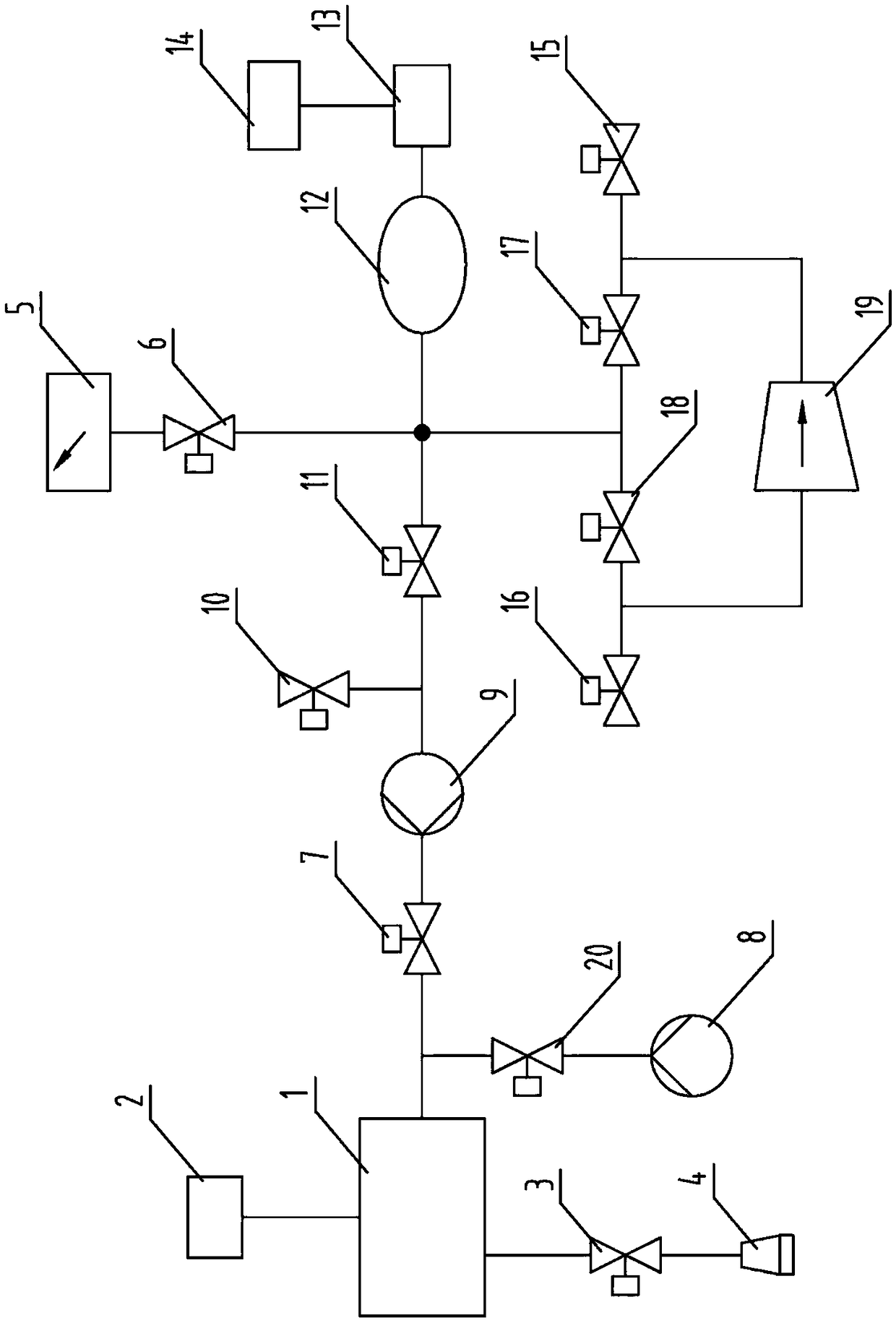

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] In the present invention, referring to the flow direction of gas from front to back, the inlet end is defined as the front end, and the outlet end is defined as the rear end accordingly.

[0032] The gist of the present invention is to complete the sealing detection through the following steps:

[0033] (1) Vacuuming: Put the inspected workpiece filled with the detection medium into the confined space, and evacuate the confined space until the air pressure in the confined space is lower than 3000Pa;

[0034] (2) Cleaning: the gas in the sampling mechanism is discharged into an empty state;

[0035] (3) Sampling: After step (1) vacuuming and step (2) cleaning are completed, the sampling mechanism is connected, and the sampling mechanism extracts sample gas from the confined space, and converts the sample gas from a vacuum state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com