Water inlet structure vortex control device based on equal difference variable diameter arc

A circular arc and contour technology, applied in the field of pump station engineering, can solve the problems of poor structural stability and many consumables of hollow vortex elimination devices, and achieve the effects of improving inlet water flow conditions, reducing energy consumption and eliminating vortex belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

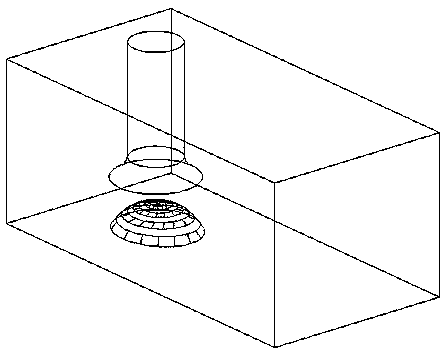

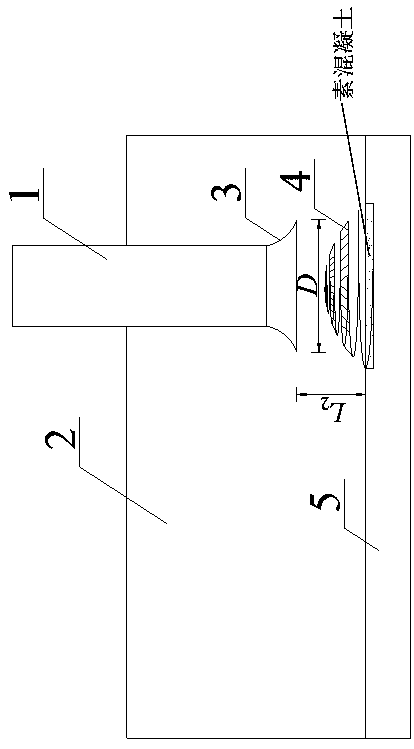

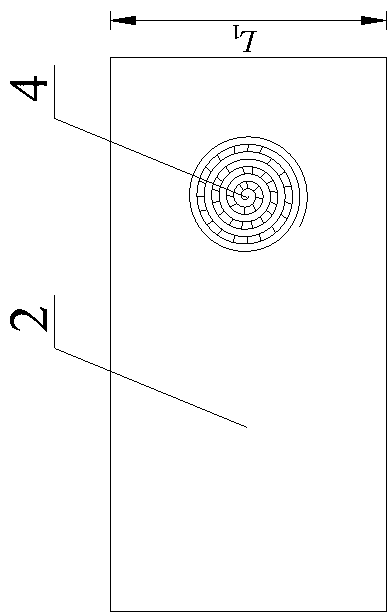

[0030] like figure 1As shown, a water intake structure vortex control device based on the equal difference variable diameter arc line, with the width of the water intake structure and the suspended height of the horn tube as constraints, the value of the number of variable diameter n is determined, and the equal difference variable The radial arc line is drawn into a plane curve, and the steel bar is used to make it according to the plane curve, and the anti-rust paint is painted after production. Then, according to the suspended height of the horn tube, the stretching length of the equal-difference variable-diameter arc line is determined, and the plane curve is stretched into a vortex control device by simple mechanical stretching equipment. After the reinforcement is completed, place the vortex control device as a whole in the cylindrical gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com