Main cable saddle of assembled back cable structure

A main cable saddle and assembly technology, which is applied in the field of cable saddles of suspension bridges, can solve the problems of increased difficulty in processing the cable saddle body, difficulty in ensuring processing quality, and low pass rate of the main cable saddle, and achieve reliable and stable processing quality And the effect of good reliability and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

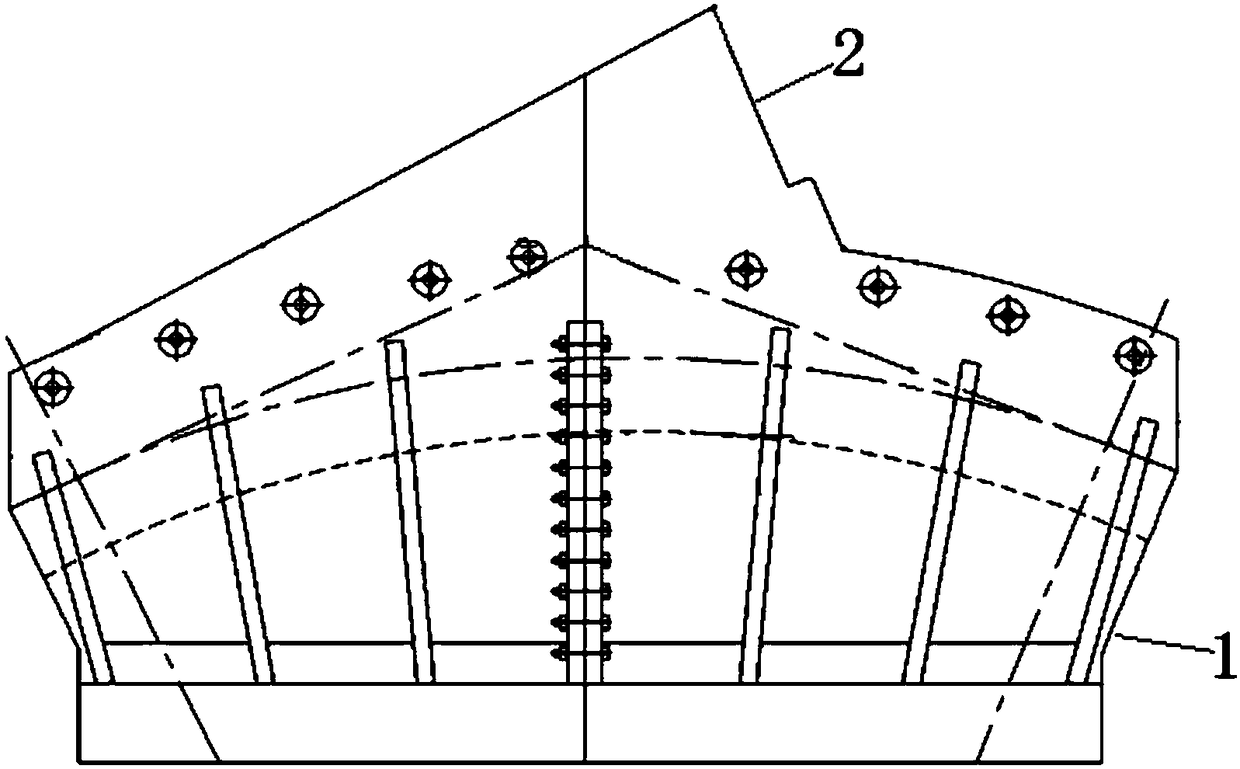

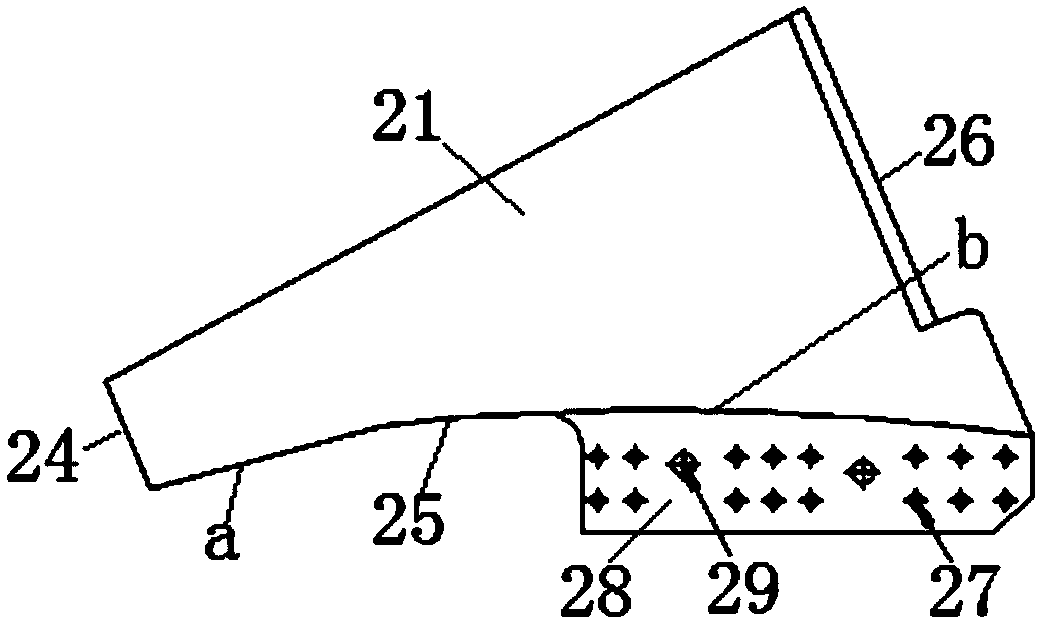

[0029] see figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes a cable saddle body 1 and a back cable anchor 2 with a split structure.

[0030] Wherein, the cable saddle body 1 is mainly composed of side-span side 11 and middle-span side 12 of the split structure, which are locked together by a plurality of locking bolts on the joint surface of the middle part. The side span side 11 and the mid-span side 12 of the cable saddle body 1 have through saddle grooves, and saddle groove wall panels stand upright on both sides of the saddle groove, and the top profile of the saddle groove wall panels on each side is basically arched. Curved lines.

[0031] The inner side of the saddle wall plate on each side of the cable saddle body 1 is provided with a limit groove 14 in a sinking manner, and the limit groove 14 on each side is located at the upper part of the saddle wall plate on the mid-span side 12 close to the middle joint surf...

Embodiment 2

[0037] The invention includes a split-structure cable saddle body and a back cable anchor.

[0038] Among them, the cable saddle body is mainly formed by locking the side-span side and the middle-span side of the split structure through a plurality of locking bolts on the joint surface of the middle part. The side span side and the middle span side of the cable saddle body have through saddle grooves, and there are saddle groove wall panels upright on both sides of the saddle groove, and the top profile of the saddle groove wall panels on each side is basically an arched arc shape. Wire.

[0039] The outer side of the saddle groove wall plate on each side of the cable saddle body is provided with a limit groove in a sunken manner. There are multiple bolt holes arranged in multiple rows and columns on the wall plate of the groove, and two bolt holes are arranged on the wall plate of the saddle groove in the limit groove on each side corresponding to the arrangement track of th...

Embodiment 3

[0045] Other contents of this embodiment are the same as those of Embodiment 1 or 2, except that the cable saddle body is an integral structure, that is, the side span side and the middle span side are integrally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com