Socket type rebar cage structure in steel pipe column and connection method of socket type rebar cage structure

A construction method and steel cage technology, applied in the direction of structural elements, columns, pier columns, etc., can solve problems such as potential safety hazards, inability to apply steel cage construction, and existence of steel pipe column operating environments, so as to ensure the safety of construction operations and increase safety Coefficient, the effect of firm and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

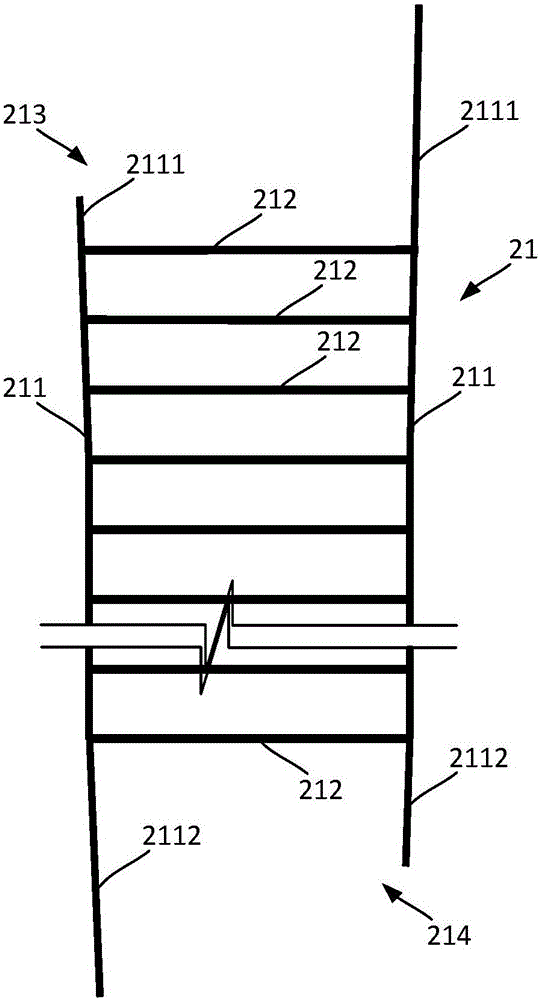

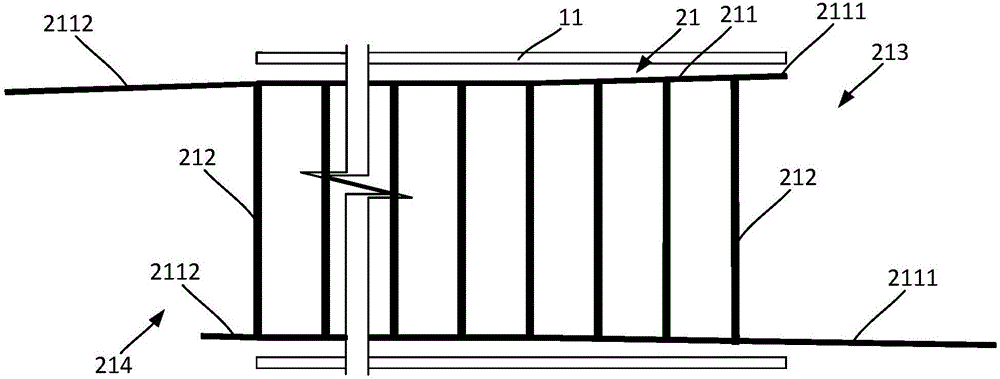

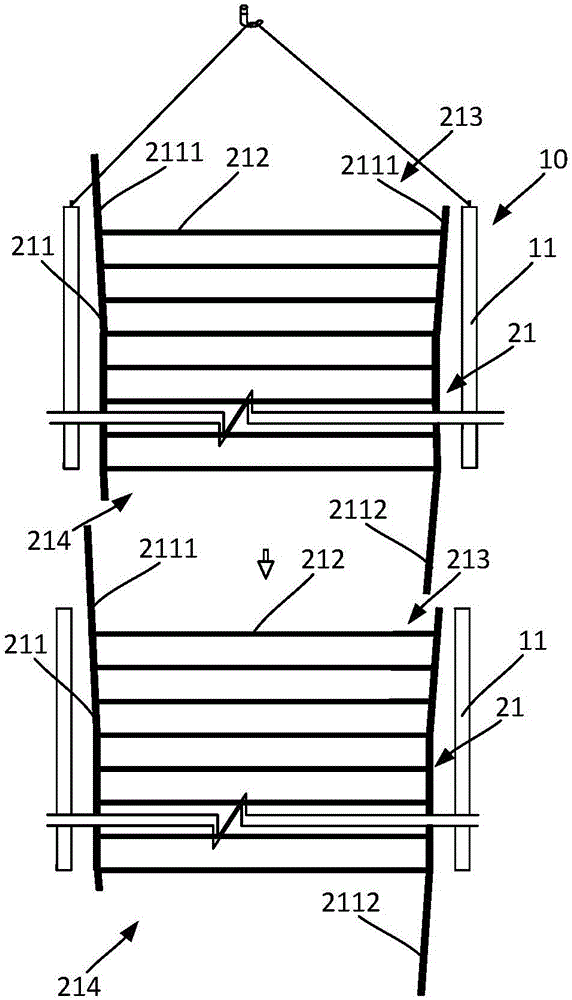

[0032] The present invention provides a socket-type reinforcement cage structure in a steel pipe column and a construction method thereof. It is used for the construction of steel pipe columns with narrow inner cavity space and the poor working environment of the inner cavity will easily cause safety hazards. The invention provides a socket-type reinforcement cage structure. The upper and lower reinforcement cage units are connected by plugging each other, and the small end of the upper reinforcement cage unit is inserted into the large end of the lower reinforcement cage unit, so that The construction of the steel cage structure is simple and convenient, which saves the existing operation steps of fixed connection, prevents workers from going down into the steel pipe column, improves the safety factor of construction, and avoids potential safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com