Steel structure temporary fixing device and technology used for splicing of large-size capping beam cantilever

A temporary fixation and steel structure technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of long construction period, impact of on-site traffic and surrounding environment, completion of prefabricated installation, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The process of the present invention is used in the new construction of S7 Highway in Shanghai. It is actively explored in the field of bridge full prefabrication and assembly technology, and breakthroughs have been made in the fields of cap beam high block structure and deep buried anchor technology, abutment prefabrication and assembly technology.

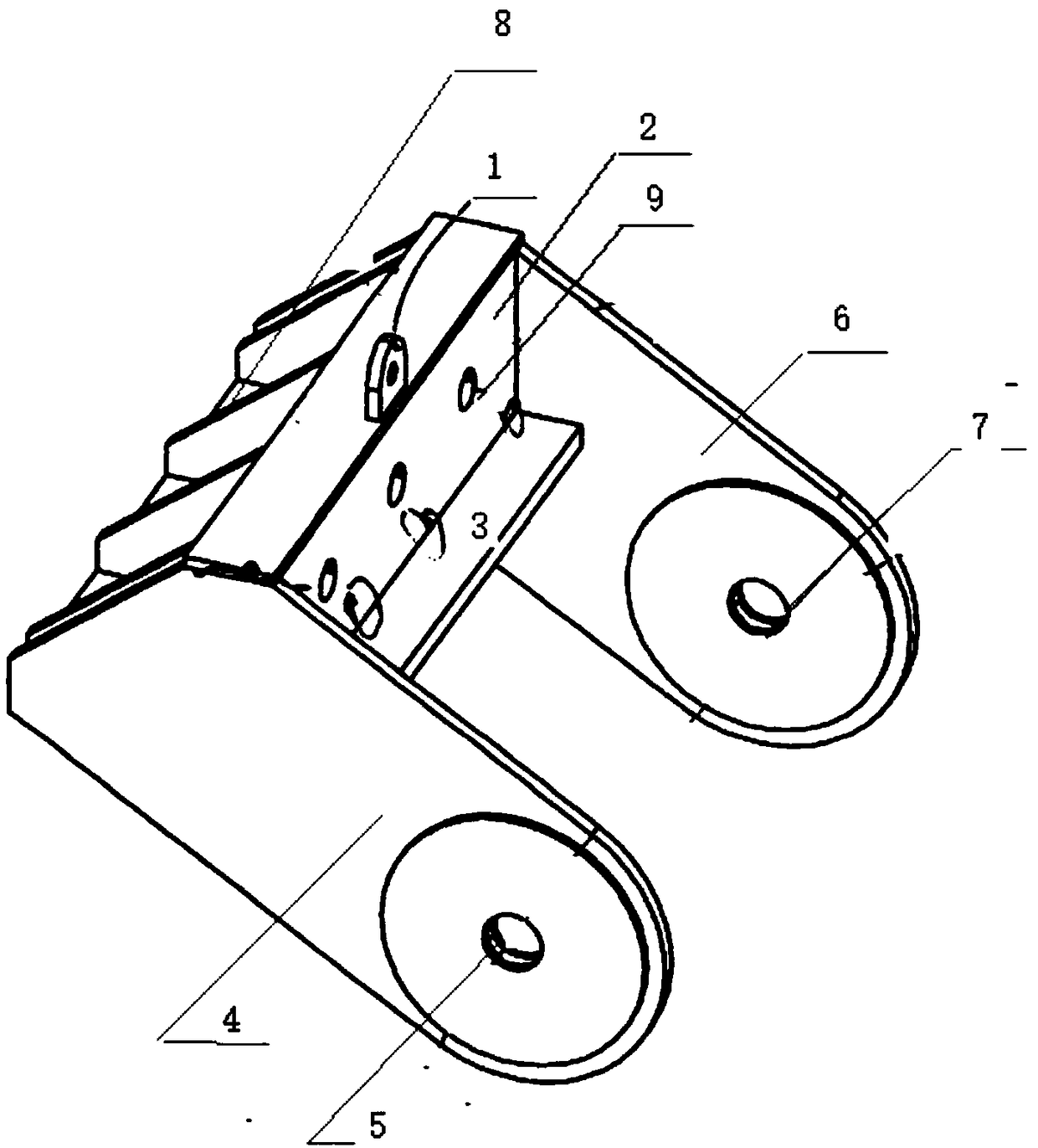

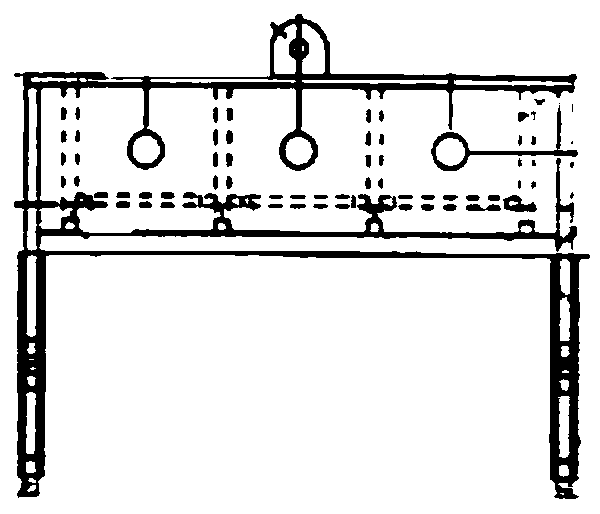

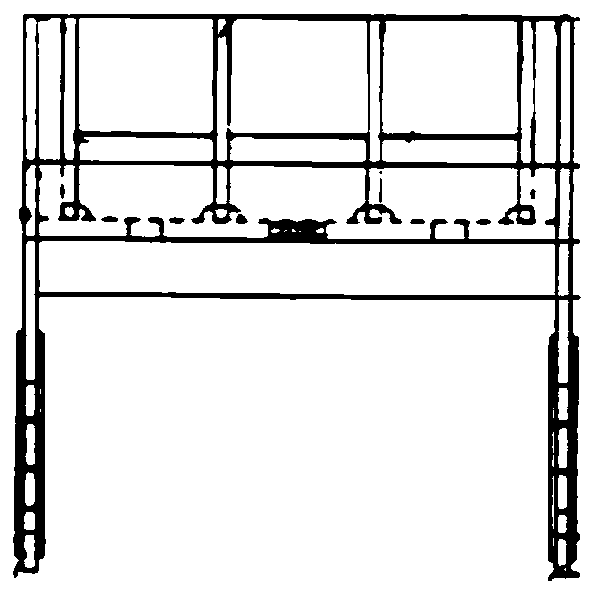

[0027] This technology divides the large cap beam into several small sections to match the prefabricated construction. The splicing surface is jointed with epoxy glue, and the joint form is a corrugated vertical joint. The miniaturization of the segments is convenient for transportation and hoisting; the matching prefabricated construction can ensure the uniform and close bonding of the joints; the splicing surface is epoxy glued to ensure the quality of the joints and rapid construction.

[0028] In particular, the first corbel-type vertical joints effectively reduce the construction difficulty and risk of construction wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com