Composite oxygen electrode for solid oxide electrolytic cell and preparation method thereof

A solid oxide and oxygen electrode technology, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of unsuitable oxygen electrodes and low electrode activity, so as to alleviate the problem of performance attenuation, improve the electrocatalytic activity of electrodes, and increase the electrolytic activity of electrodes. The effect of the chemically reactive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

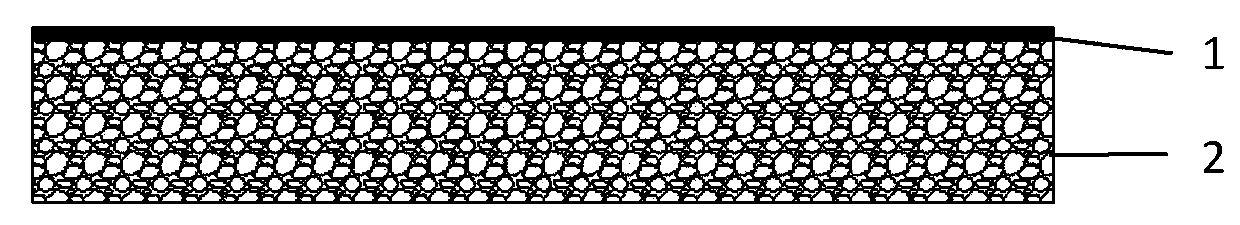

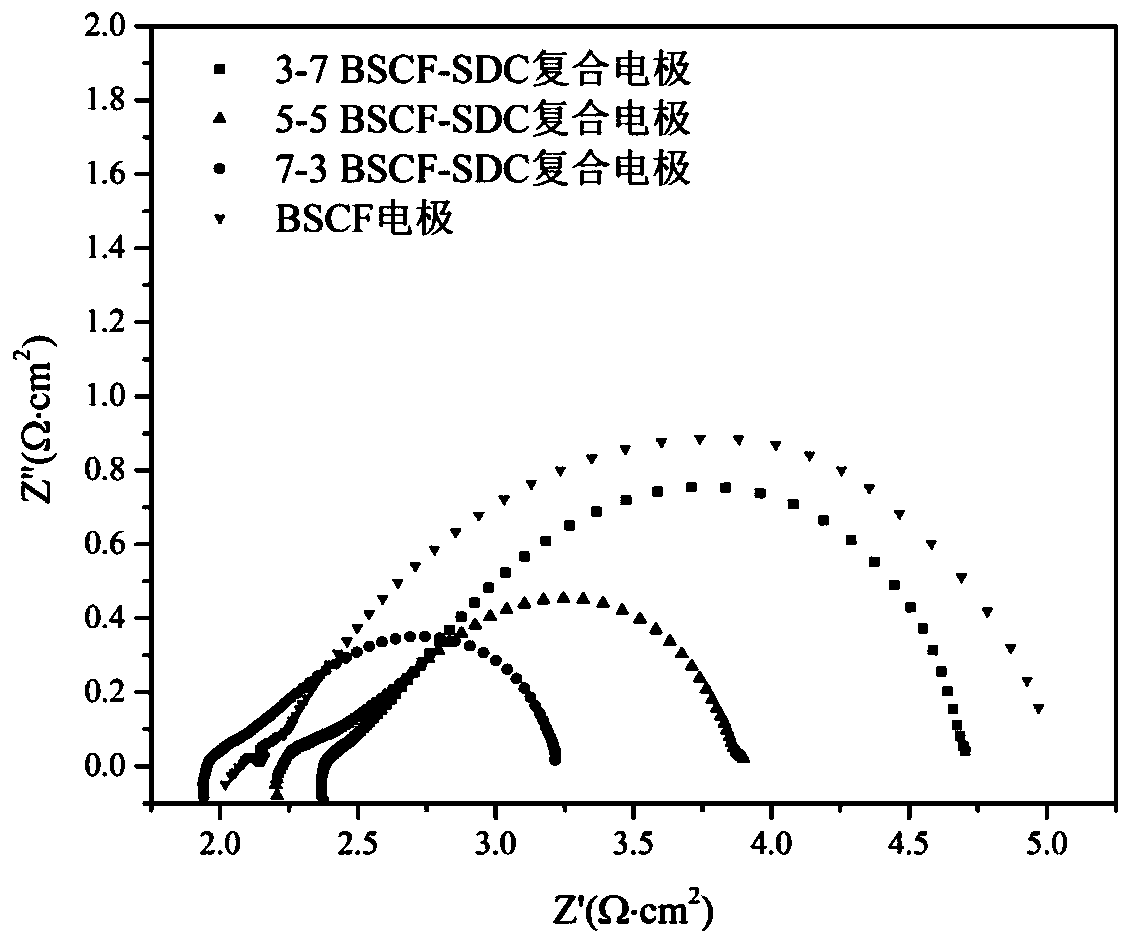

[0036] This example is Ba with different molar ratios 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ -SDC porous composite electrode;

[0037] The specific steps for preparing the new BSCF-SDC porous composite oxygen electrode:

[0038] Step 1: Preparation of Sm by sol-gel method (sol-gel) 0.2 Ce 0.8 o 1.9 (SDC) Electrolyte material powder according to Sm 0.2 Ce 0.8 o 1.9 Configure Ce(NO 3 ) 2 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O solution, using citric acid monohydrate as a complexing agent and a sintering aid, the amount of citric acid monohydrate added is 1.5 times the molar weight of the total metal ions, and the mixed solution is heated in a water bath at 70°C until it becomes gelatinous. Continue heating in a universal furnace until combustion to form SDC precursor powder, and finally calcine at a temperature of 800°C for 2 hours to obtain the SDC target powder;

[0039] Step 2: Glycine-nitrate method (GNP) prepares Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ (BSCF) material powder ...

Embodiment 2

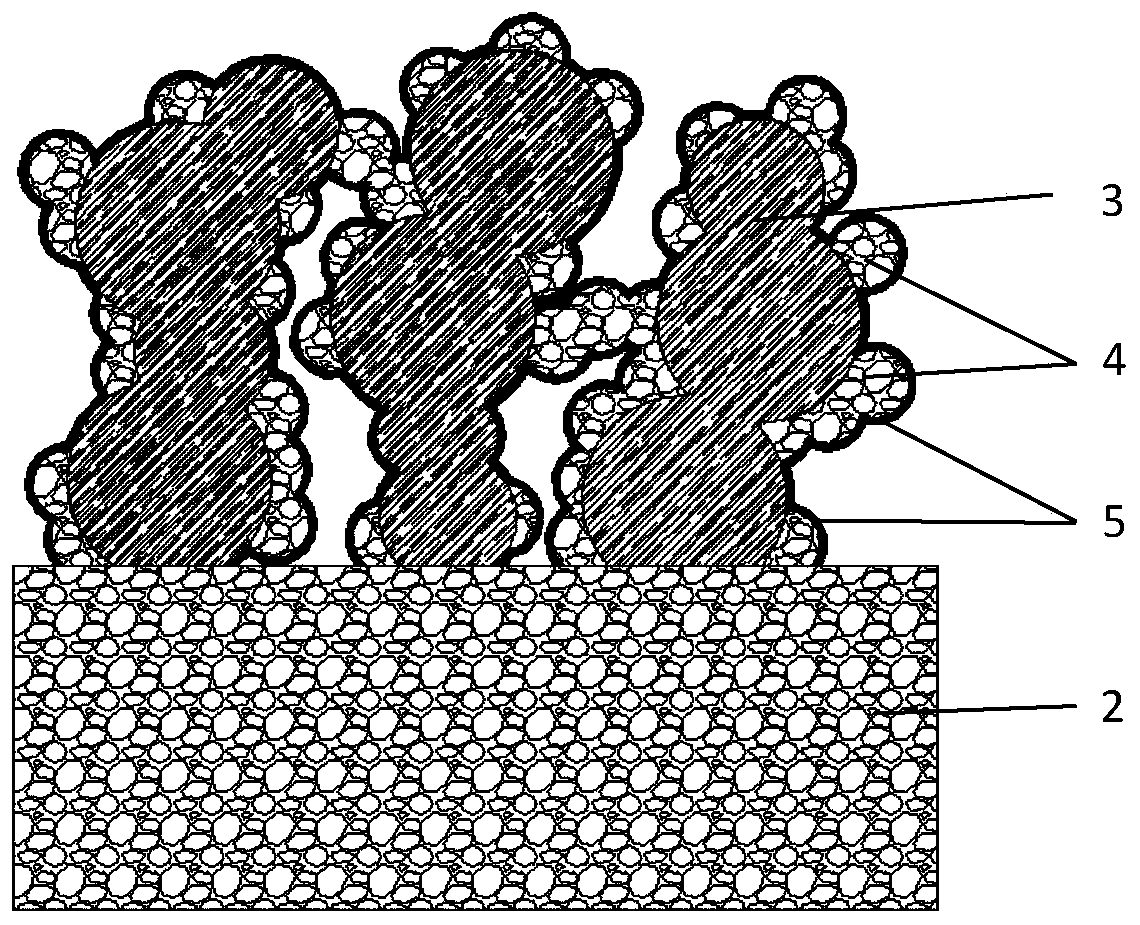

[0047] This example uses La 2 NiO 4 (LNO) as the active material, by solution in situ impregnation method for Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ -SDC porous multi-phase electrode is modified to finally obtain LNO / BSCF-SDC novel composite oxygen electrode and its preparation steps.

[0048] The specific steps for preparing the new LNO / BSCF-SDC porous composite oxygen electrode:

[0049] Step 1: Preparation of Sm by sol-gel method (sol-gel) 0.2 Ce 0.8 o 1.9 (SDC) Electrolyte material powder according to Sm 0.2 Ce 0.8 o 1.9 Configure Ce(NO 3 ) 2 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O solution, using citric acid monohydrate as a complexing agent and a sintering aid, the amount of citric acid monohydrate added is 1.5 times the molar weight of the total metal ions, and the mixed solution is heated in a water bath at 70°C until it becomes gelatinous. Continue heating in a universal furnace until combustion to form SDC precursor powder, and finally calcine at a temperature of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com