A kind of preparation method of gas barrier film

A gas barrier and film technology, which is applied in the field of gas barrier film preparation, can solve the problems of reduced film barrier properties and high production costs, and achieve the effects of inhibiting the reduction of gas barrier properties, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A 100 μm thick polyethylene terephthalate (PET) film was used as a flexible transparent substrate, and the PET substrate was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then dried with dry N2, and then the PET The substrate is placed on the surface of the lower electrode plate of the plasma enhanced chemical vapor deposition (PECVD) vacuum chamber. Evacuate the vacuum chamber to a background vacuum of 1.0×10 -3 Pa, then pass Ar gas into the plasma generation chamber of PECVD, and then turn on the radio frequency power supply, under the pressure of 5 Pa, use Ar plasma to carry out surface treatment on the substrate for 60 seconds, then turn off the radio frequency power supply and stop the Ar gas access.

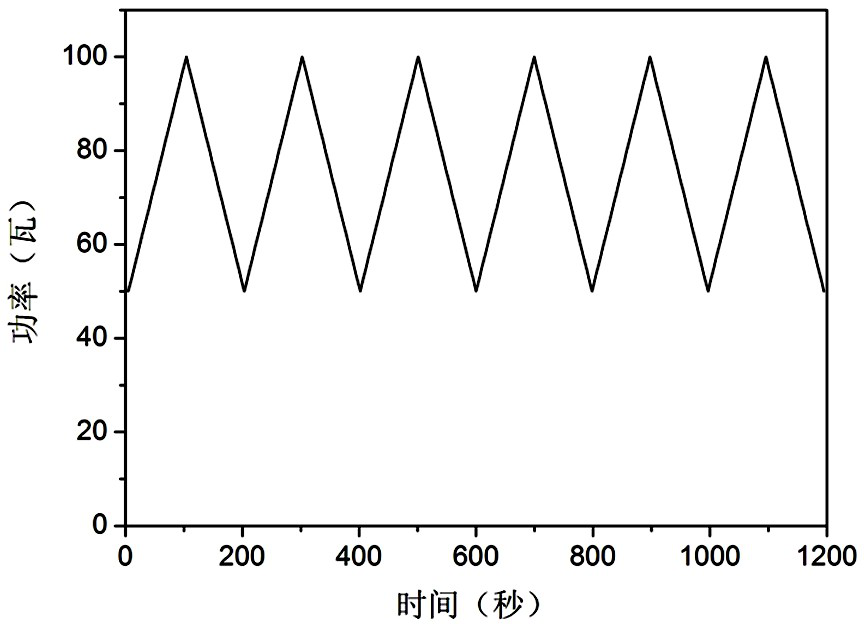

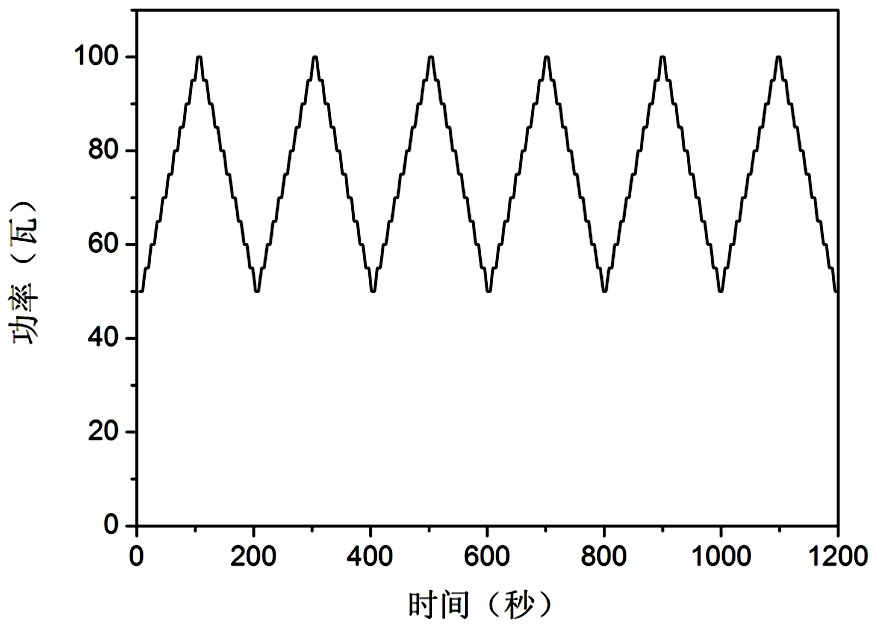

[0039] After that, HMDSO monomer vapor (10 sccm) and O 2 (80 sccm) is passed into the vacuum chamber through different pipelines, and the working pressure is adjusted to 2 Pa through the gate valve. Turn on the power switch of ...

Embodiment 2

[0042] A 100 μm thick PET film was used as a flexible transparent substrate, and the PET substrate was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and then dried with N 2 Blow dry, and then place the PET substrate on the surface of the lower electrode plate of the plasma enhanced chemical vapor deposition (PECVD) vacuum chamber. Evacuate the vacuum chamber to a background vacuum of 1.0×10 -3 Pa, then pass Ar gas into the plasma generation chamber of the plasma-enhanced chemical vapor deposition device, then turn on the radio frequency power supply, and use Ar plasma to carry out surface treatment on the substrate under a pressure of 5 Pa for 60 seconds, and then turn off RF power supply and stop the introduction of Ar gas.

[0043] After that, HMDSO monomer vapor (10 sccm) and O 2 (80 sccm) through different pipelines into the plasma-enhanced chemical vapor deposition vacuum chamber of the film, and the working pressure is adjusted to 2 Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com