Bead-blasting base oil with natural cream fragrance and preparation method of base oil

A technology of base oil and natural flavors, which is applied in the field of flavors and fragrances for tobacco. It can solve the problems of weak aroma of synthetic flavors, influence on the formation of popping beads, unstable state of popping beads, etc., and achieve the effect of rich aroma, thin aroma and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

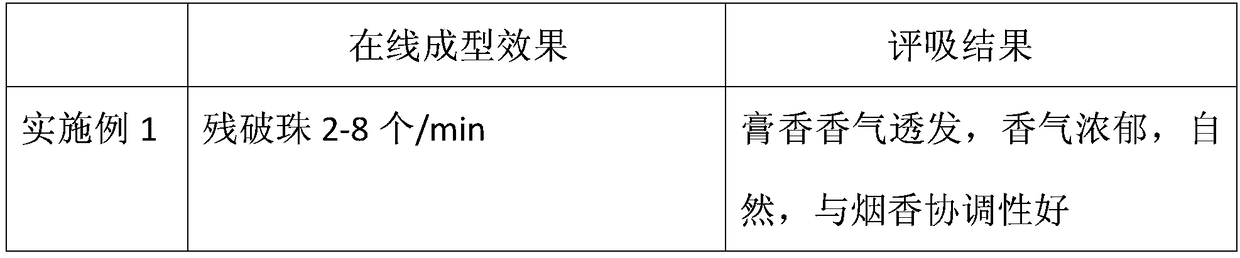

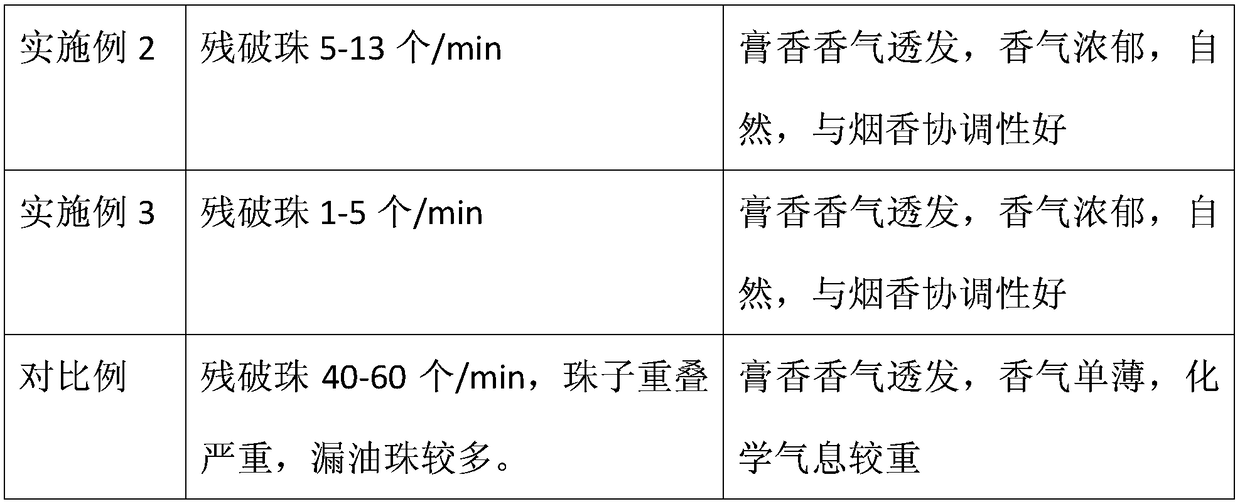

Embodiment 1

[0014] A kind of quick-fried bead base oil with natural ointment fragrance provided by Example 1, its preparation method is as follows: take 50 g of styrax raw material and 50 g of benzoin raw material, grind them into powder respectively and mix them evenly, add Xin Gui which is 150 times the weight of the mixed raw materials Glycerides, soaked at room temperature for 12 hours, then ultrasonicated for 4 hours at a temperature of 45 ° C and an ultrasonic frequency of 30 kHz, filtered after the ultrasonic wave was completed, impurities and insolubles were removed, and left standing for 24 hours. Rhyme's Beaded Base Oil.

Embodiment 2

[0015] A kind of quick-fried pearl base oil with natural paste fragrance provided by embodiment 2, its preparation method is as follows:

[0016] Take 100g of styrax raw material and 50g of benzoin raw material, grind them into powder and mix them evenly, add caprylic capric acid glyceride accounting for 200 times the weight of the mixed raw materials, soak at room temperature for 24h, and then ultrasonicate for 3h at 50°C and ultrasonic frequency of 27kHz , after the ultrasonic wave is finished, filter to remove impurities and insoluble matter, and let it stand for 24 hours, which is the pearl base oil with natural paste fragrance.

Embodiment 3

[0017] A kind of quick-fried pearl base oil with natural paste fragrance provided by embodiment 3, its preparation method is as follows:

[0018] Take 50g of styrax raw material and 150g of benzoin raw material, grind them into powder and mix evenly, add caprylic capric acid glyceride accounting for 100 times the weight of the mixed raw materials, soak at room temperature for 12 hours, and then ultrasonicate at 60°C and ultrasonic frequency 35kHz 2h, filter after sonication to remove impurities and insoluble matter, and let stand for 24 hours, which is the base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com