Resveratrol based flame retardance epoxy resin and preparation method thereof

A technology of epoxy resin and resveratrol, which is applied in the field of resveratrol-based flame-retardant epoxy resin, can solve the problems of poor flame retardancy, high toxicity of raw materials, non-renewable, etc., achieve high cross-linking density, improve resistance The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

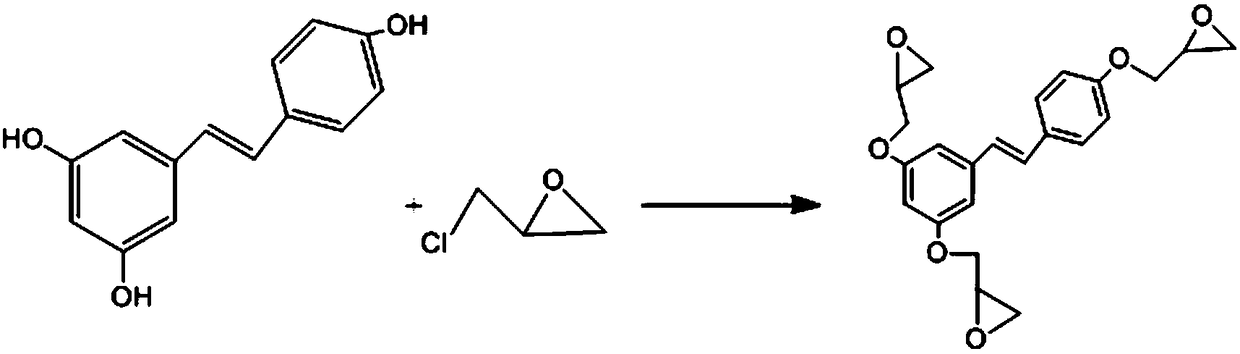

[0057] (1) Add 0.008762 mol of resveratrol to a round bottom flask with a condenser tube, and place it under N2 environment. Add 0.07mol epichlorohydrin into the flask at room temperature, heat to 70°C, slowly add 11.683g 30wt% NaOH solution, and keep the reaction mixture at this temperature for 30min. After cooling to room temperature, the product was obtained by filtration, washed three times with xylene, and then vacuum-dried at 30° C. for 8 h to obtain the product RA1.

[0058] (2) Add 0.01 mol of abietic acid to a three-neck flask equipped with mechanical stirring, heating and condensing tubes, raise the temperature to 100°C under nitrogen protection and maintain heating at this temperature for 1 hour, then slowly cool to 100°C, and add 40mL of glacial acetic acid , 0.018mol of maleic anhydride and 0.033g of ferric chloride were reacted under reflux for 3h. Cool to room temperature and filter directly to obtain a light yellow solid, which is recrystallized twice with gla...

Embodiment 5

[0064] (1) Add 0.008762mol resveratrol in the round bottom flask with condenser tube, place N 2 in environment. Add 0.07mol epichlorohydrin into the flask at room temperature, heat to 130°C, slowly add 11.683g 30wt% NaOH solution, and keep the reaction mixture at this temperature for 90min. After cooling to room temperature, the product was obtained by filtration, washed three times with dichloromethane, and then vacuum-dried at 100° C. for 12 h to obtain the product RA1.

[0065] (2) Add 0.019mol RA1 N,N-dimethylformamide solution (180ml) into a round bottom flask with a condenser tube, add 0.0095mol zinc chloride to the solution, stir vigorously, slowly add 0.0228mol Triethyl phosphate, and the reaction mixture was kept at 40°C for 15h. After the reaction, N,N-dimethylformamide was removed. Add 300ml of dichloromethane, wash with saturated ammonium chloride solution and deionized water three times in turn, dry the organic phase with anhydrous sodium sulfate, filter to rem...

Embodiment 6

[0072] (1) Add 0.008762 mol of resveratrol to a round bottom flask with a condenser tube, and place it under N2 environment. 0.07mol epichlorohydrin was added into the flask at room temperature, heated to 100°C, 11.683g 30wt% NaOH solution was slowly added, and the reaction mixture was kept at this temperature for 60min. After cooling to room temperature, the product was obtained by filtration, washed with butanone three times, and then vacuum-dried at 80° C. for 10 h to obtain the product RA1.

[0073] (2) add the tetrahydrofuran solution (100ml) of 0.019mol RA1 in the round-bottomed flask with condensing tube, join 0.0095mol triethylamine in the solution, vigorously stir, slowly add 0.0228mol triethyl phosphite, reaction mixture is in Keep at 30°C for 10h. After the reaction was complete, tetrahydrofuran was removed. Add 200ml butanone to wash twice, the organic phase is dried with anhydrous sodium sulfate, and the sodium sulfate is removed by centrifugation.

[0074] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com