Self-powered semiconductor photocatalytic device with WSA position sensitive structure

A photoelectric catalysis and semiconductor technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, special compound water treatment, etc., can solve the problem of energy consumption, complex structure of photocatalytic devices, and incomplete catalytic purification effect of semiconductor photocatalytic devices being in the best condition etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

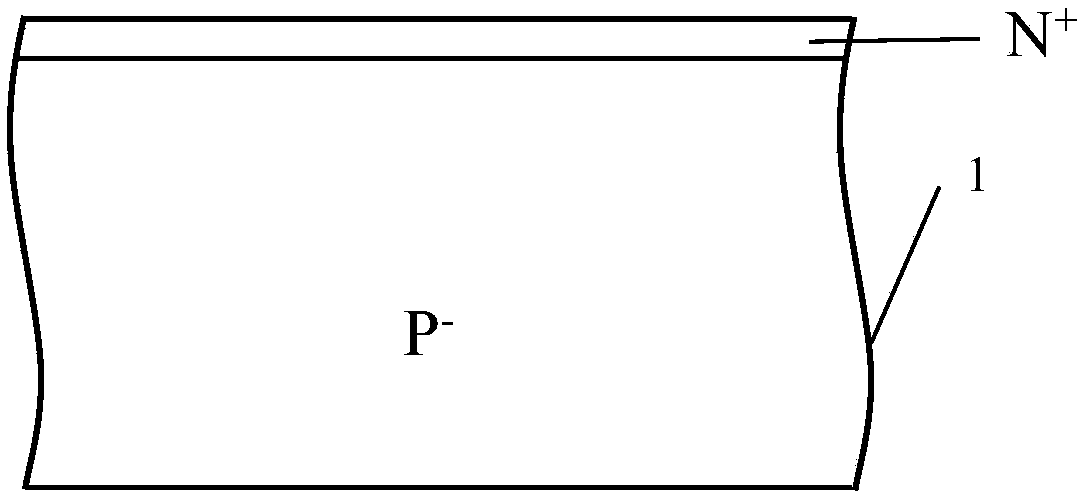

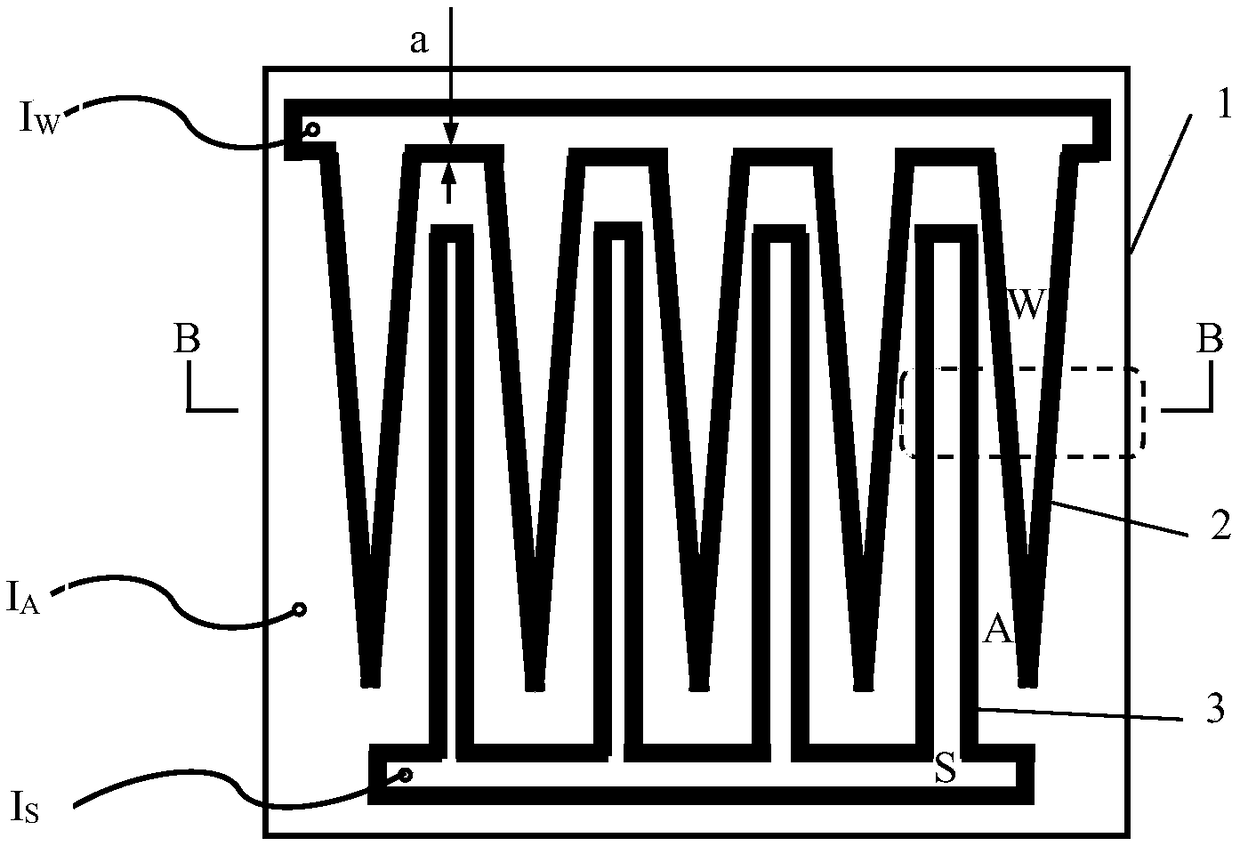

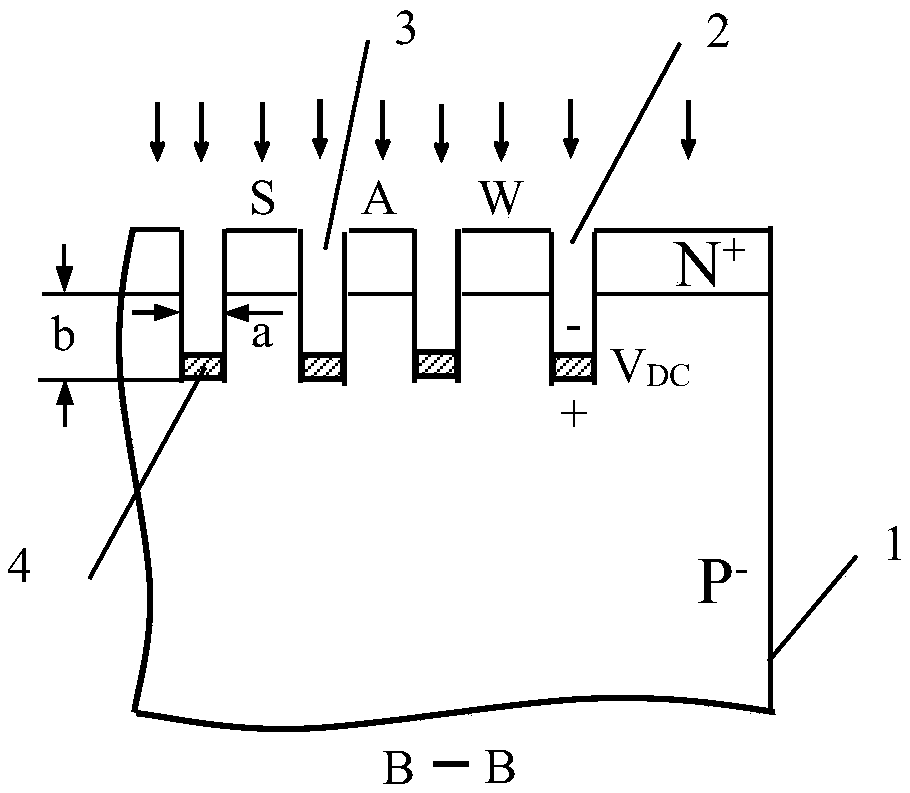

[0010] Self-powered semiconductor photocatalytic device with WSA position-sensitive structure of the present invention such as Figure 1 ~ Figure 3 As shown, at P - N + N of Wafer 1 + A set of wedge-shaped anodes W and a set of strip-shaped anodes S, P are distributed across the surface of the zone - N + Silicon wafer 1 thick 600μm, N + The thickness of the area is 20 μm, the part between the wedge-shaped anode W and the strip-shaped anode S is the third anode A, the wedge-shaped anode W, the strip-shaped anode S, and the third anode A are separated by the wedge-shaped anode channel 2 and the strip-shaped anode channel 3; The channel width a of the wedge-shaped anode channel 2 and the strip-shaped anode channel 3 is 100-120 μm, such as 100 μm, and the bottom of the channel is located at P - area, the channel is located at P - The depth b of the zone part is 50-120 μm, such as 120 μm, and a semiconductor nanowire photocatalytic layer 4 is distributed at the bottom of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com