Vacuum pipeline traffic train

A technology for vacuum pipes and vehicles, which is applied to roads, tracks, tunnel systems, etc., can solve the problems of reduced vehicle structure integrity and inability to improve the efficiency of passengers getting on and off the bus, and achieve simplified vehicle structure, superior integrity, and convenient boarding and alighting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

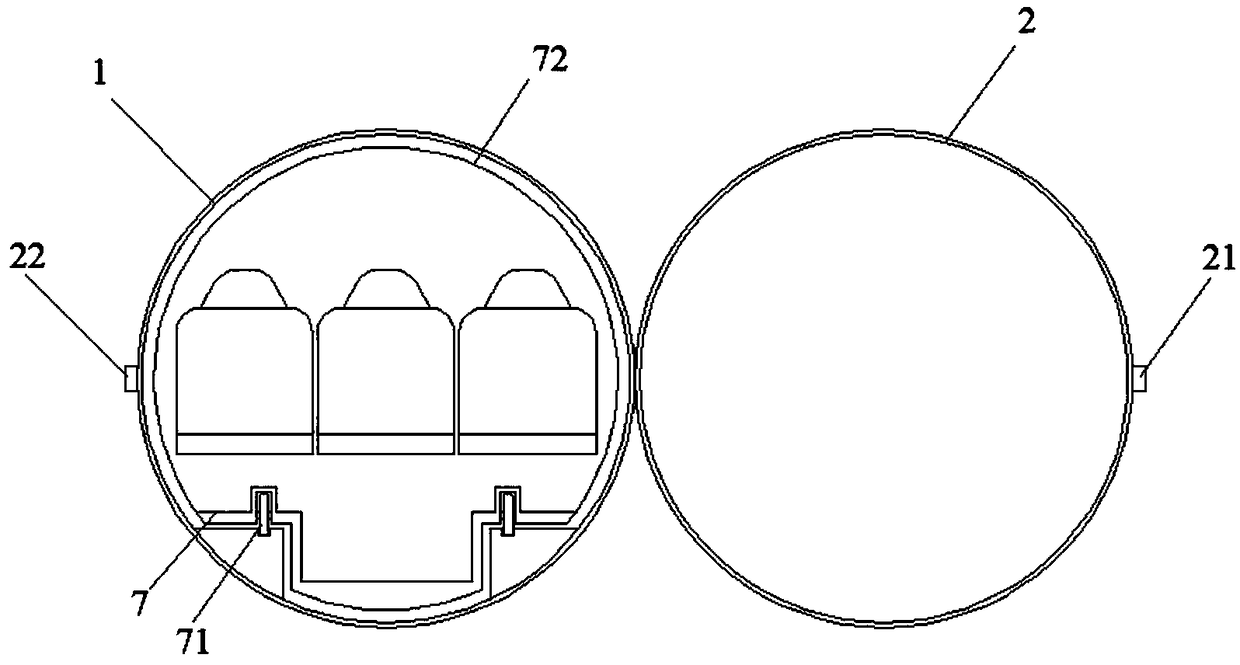

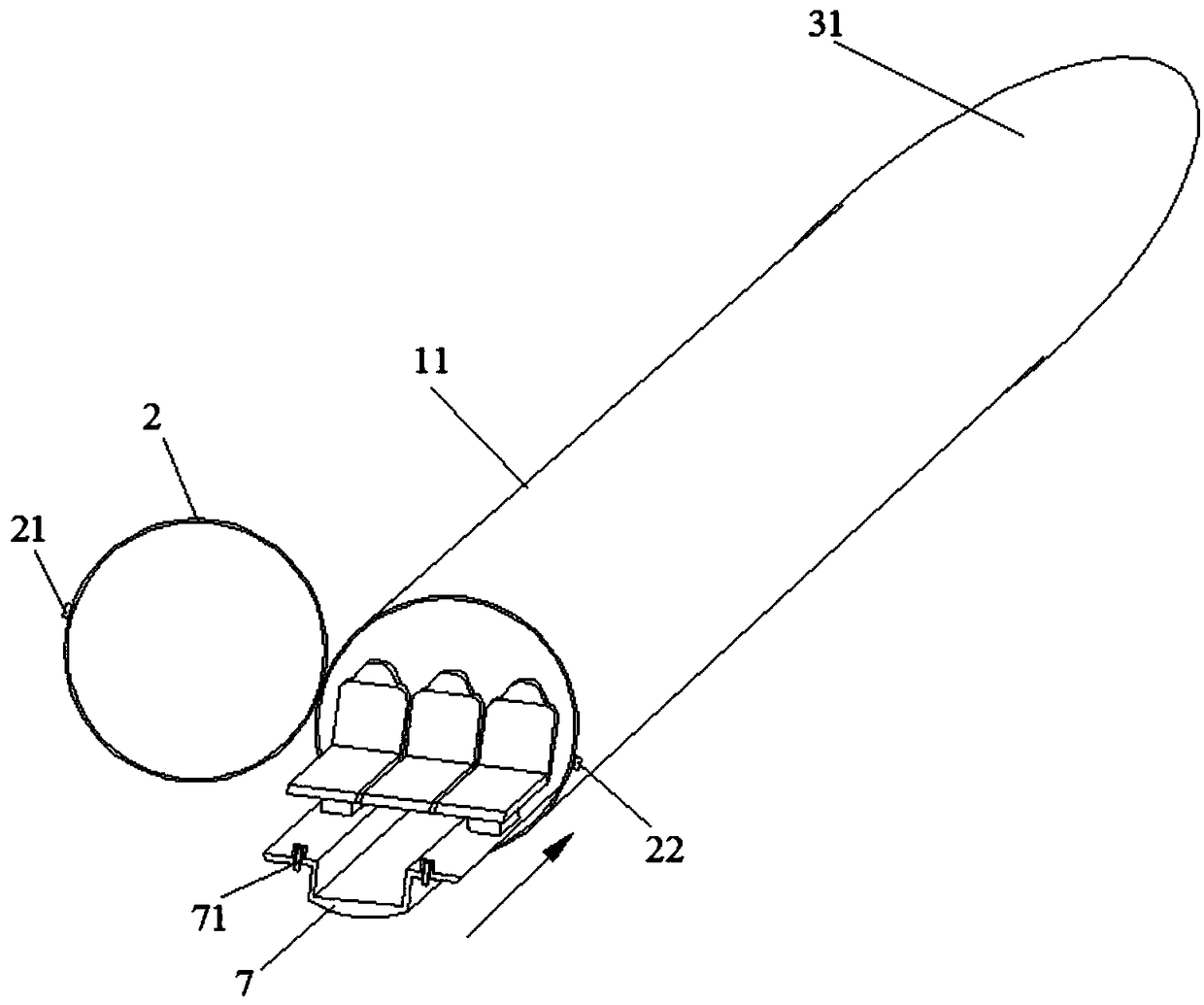

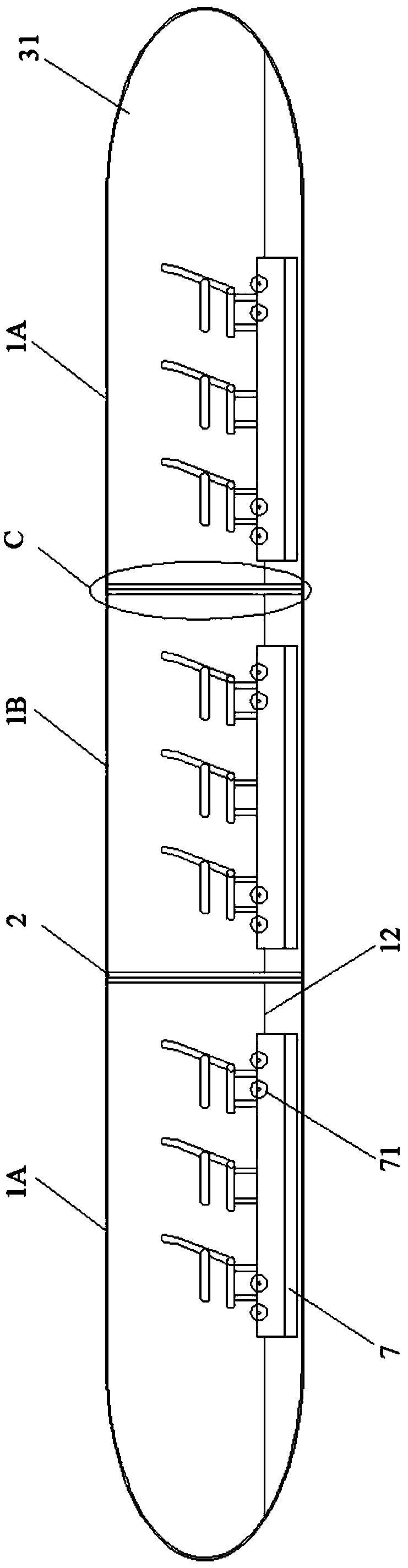

[0059] refer to Figure 1-3 , taking the vacuum pipeline vehicle provided with the end door 2 as an example, the vehicle has a power plant and is essentially a vehicle capable of autonomous operation.

[0060] Design and manufacture a head / tail vehicle 1A with a streamlined shape, and an end door 2 is provided at the other end of the head / tail vehicle 1A. Design and manufacture an intermediate vehicle 1B with a streamlined shape. An intermediate vehicle head 32 is provided at one end to form an integral body with the vehicle shell 11 ; an end door 2 is provided at the other end. On the end door 2 and on the vehicle shell 11, an upper locking device 21 on the end door and an upper locking device 22 on the vehicle shell are respectively arranged. Design and manufacture the mobile seat car 7 that seat is installed.

[0061] When starting to run, the mobile seat car 7 is parked in the passenger area, and passengers can easily and flexibly get on the bus from both sides and front...

Embodiment 2

[0064] refer to Figure 4 , 9 , 10, take the vacuum pipeline vehicle without end door 2 as an example.

[0065] Design and manufacture a head / tail vehicle 1A with a streamlined shape, the other end of the head / tail vehicle 1A is open, and 4-6 groups of locking bolts 6 are arranged along the periphery. Design and manufacture the intermediate vehicle 1B of the endless door 2, both ends of which are kept open; the ends are provided with flanges 5 and locking bolts 6, arranged along the periphery of the open end, a total of 4-6 groups. Design and manufacture the mobile seat car 7 that seat is installed.

[0066] When starting to run, the lights and other systems in the vehicle are turned on, and the mobile seat car 7 is parked in the passenger boarding area. Car 7 sails toward vehicle along existing guide rail or automatic guide device, and mobile seat car 7 parking positions can be close to far from the vehicle parking position, and also can be close to; Mobile seat car 7 ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com