Electric hammer with composite axial spiral impact device

A technology of electric hammer and spiral groove, applied in the field of electric tools, can solve the problems of complex structure, low energy conversion efficiency, high failure rate, etc., and achieve the effect of simple structure design, low manufacturing cost, and good engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this specification and in the appended claims, "coupled" means that two parts can be connected to each other to realize the transmission of force, but it does not mean that the two parts need to be permanently connected. Instead, the two components can be coupled to each other some of the time and separated from each other at other times.

[0034] In addition, the movement direction, return direction, and impact direction of the impact member are also described in this specification and the appended claims. It should be understood that these names are only used to distinguish the movement of the impact member in different directions in one cycle, rather than to limit the absolute direction or orientation in three-dimensional space.

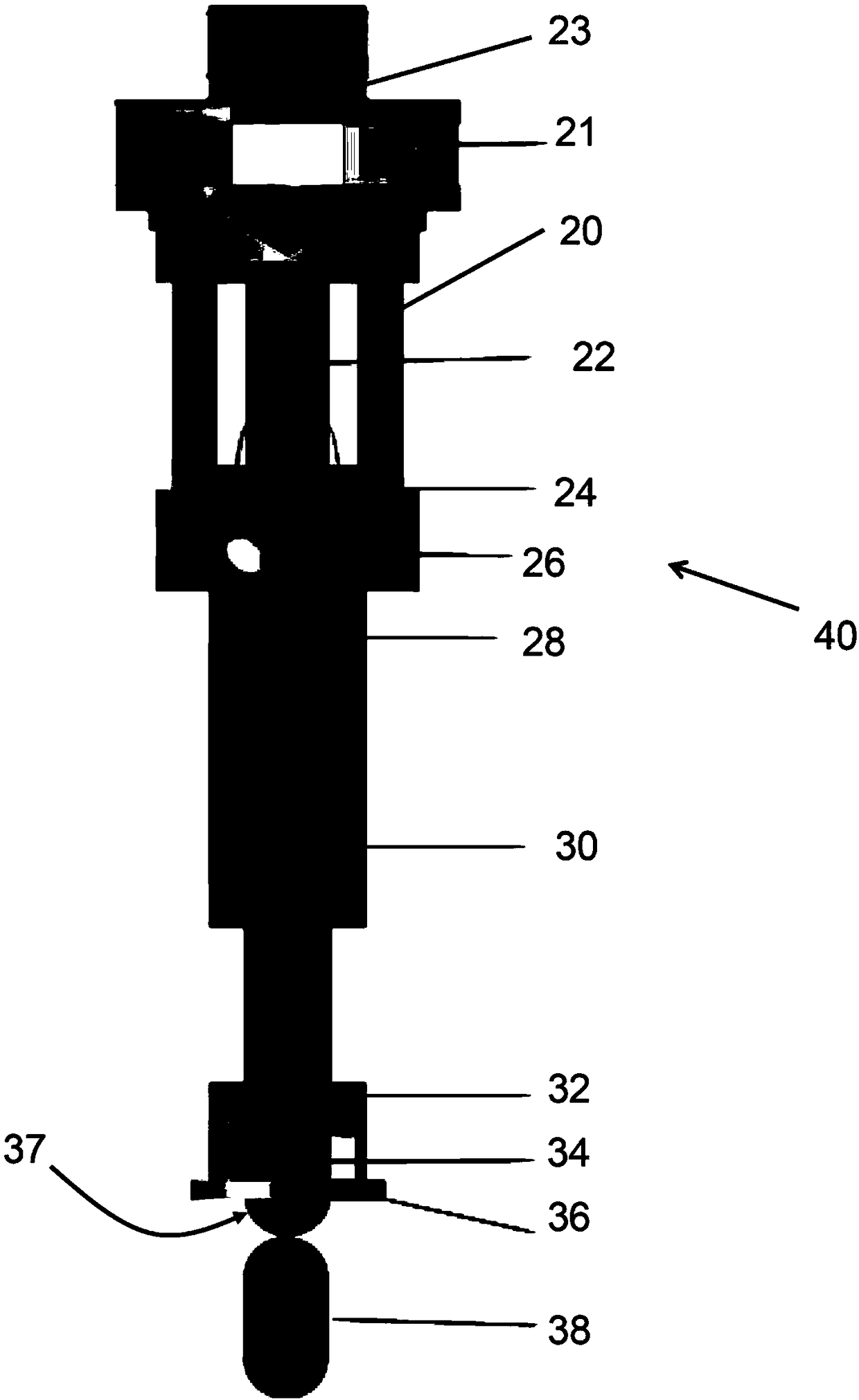

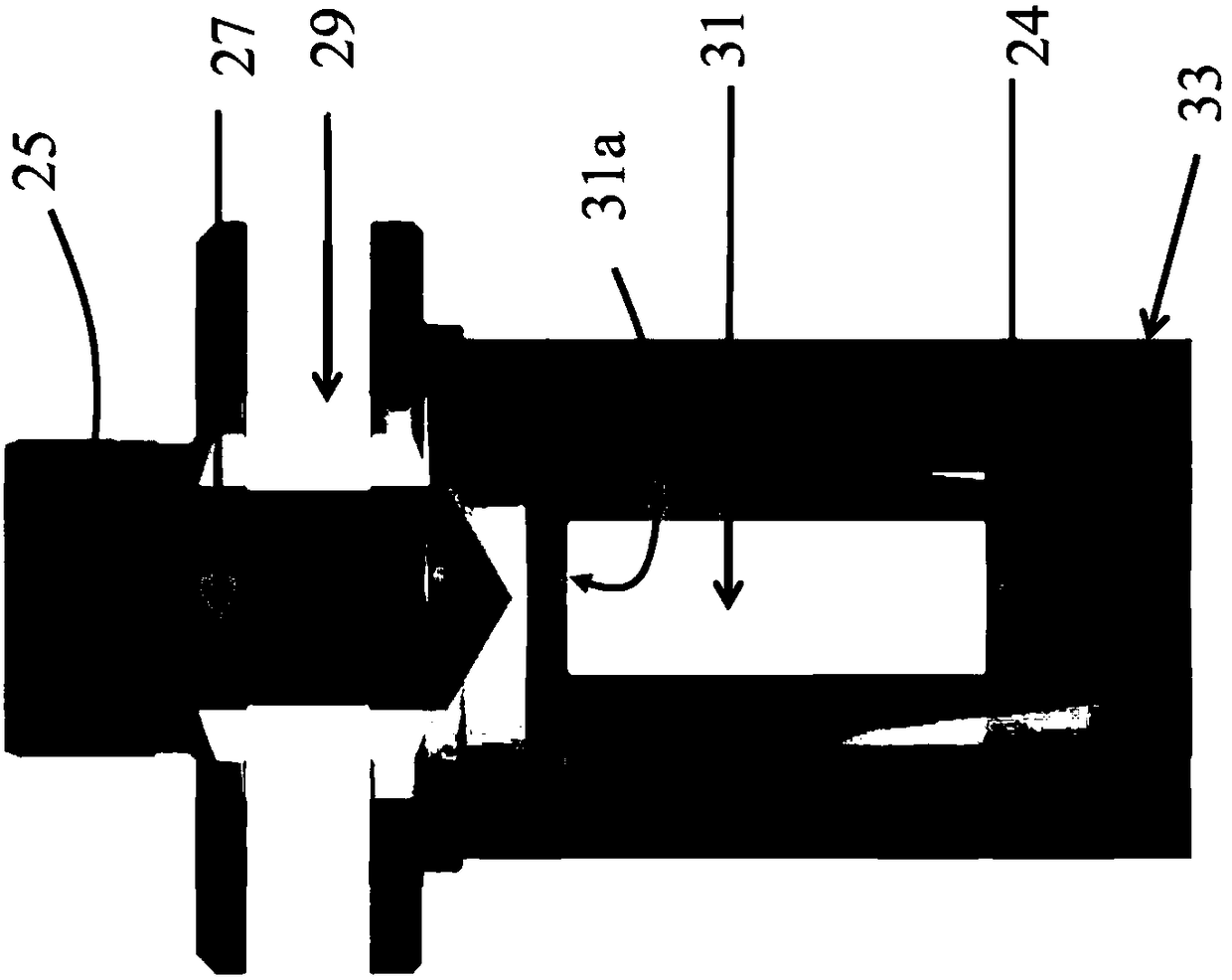

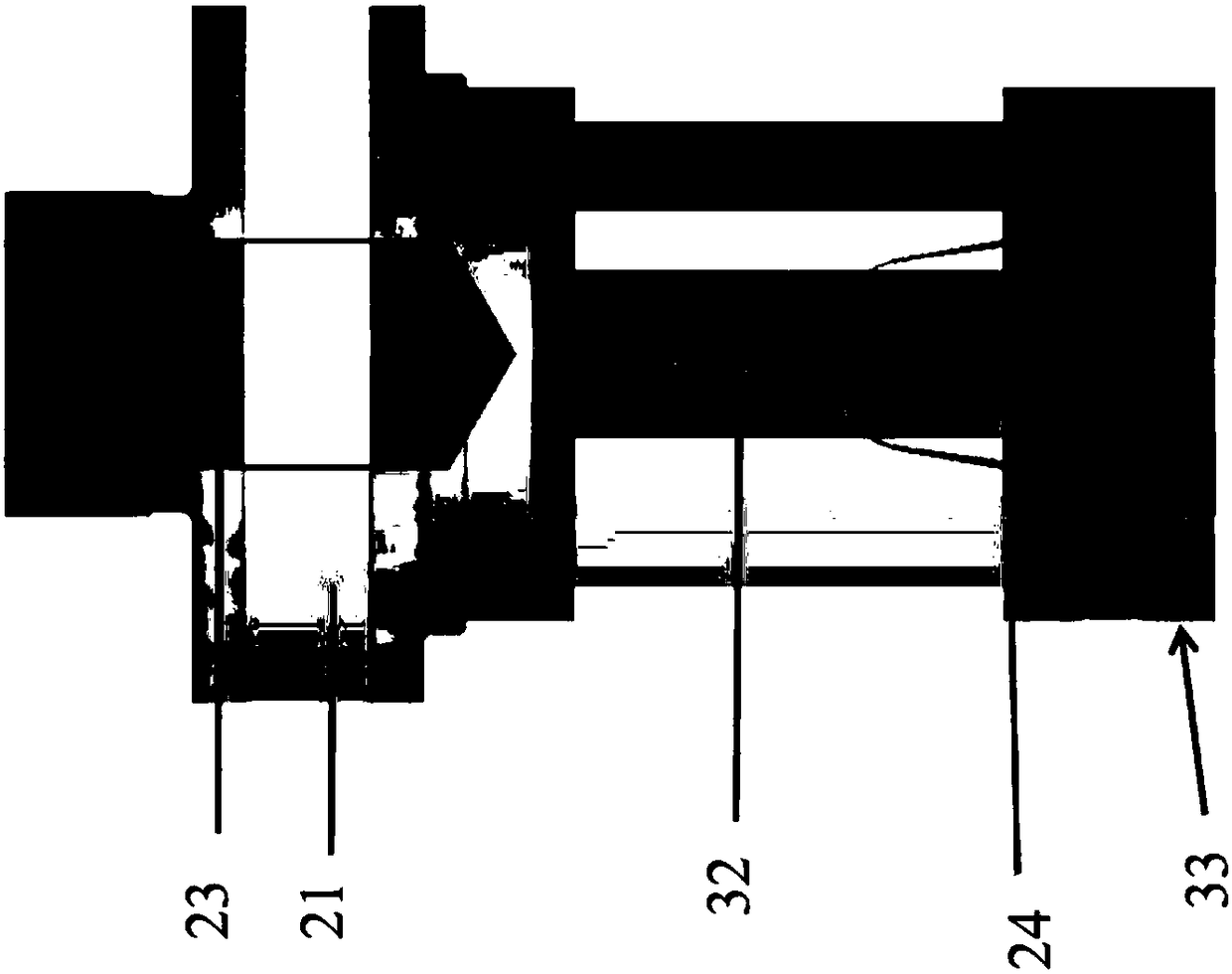

[0035] first look at figure 1 , the first embodiment of the present invention is an electric tool, specifically an electric hammer, which includes an impact mechanism 40 . The impact mechanism 40 includes a main shaft 20, and an impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com