Post-foaming cleanser and preparation method thereof

A technology of cleansing milk and foaming agent, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., which can solve problems such as skin irritation, dry skin, and large irritation of human skin, and achieve low cloud point and anti-aging Strong hard water ability and good foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

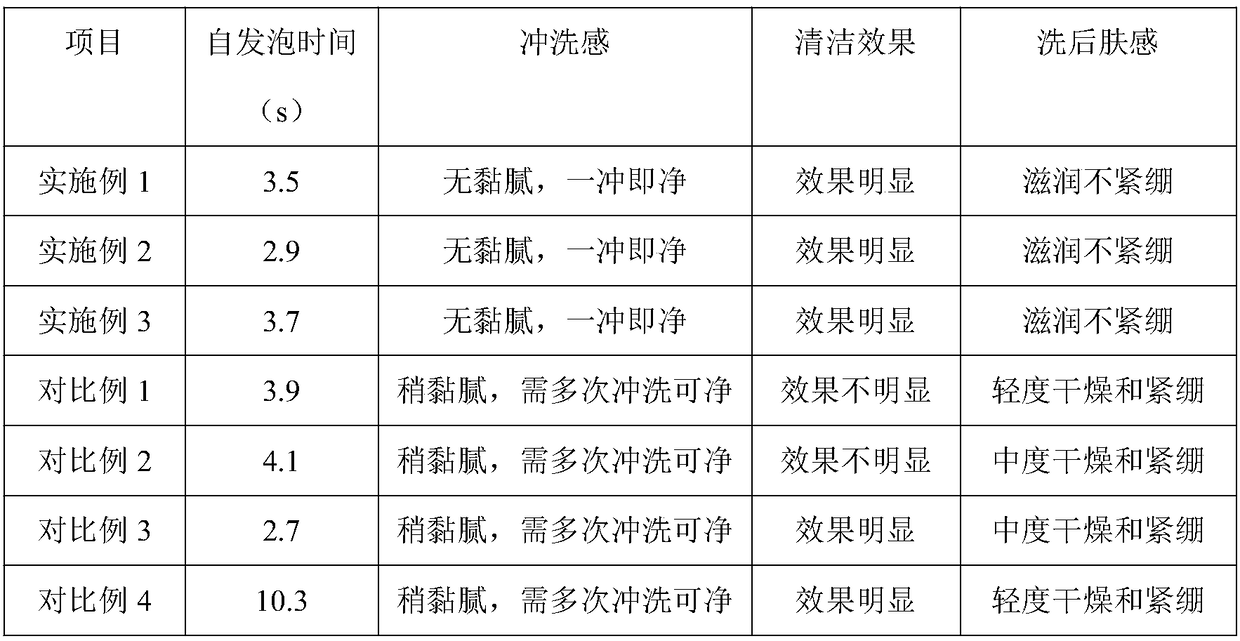

Examples

Embodiment 1

[0023] Embodiment 1, post-foaming facial cleanser of the present invention and preparation method thereof

[0024] Example 1 of the present invention post-foaming facial cleanser is composed of the following components: 10kg of surfactant, 20kg of petrolatum, 10kg of propylene glycol, 1kg of triethanolamine, 9kg of acrylic acid copolymer, trans 1-chloro-3,3,3- Trifluoropropene 4kg, hydroxyethyl cellulose 0.1kg, p-hydroxyacetophenone 0.3kg, essence 0.1kg, nitrogen 0.5kg and water 45kg.

[0025] The surfactant is sodium cocoyl isethionate, alkyl glucoside and ammonium lauryl sulfate, the sodium cocoyl isethionate, alkyl glycoside and ammonium lauryl sulfate The mass ratio is 1:0.1:0.02.

[0026] The preparation method of described post-foaming facial cleanser, comprises the following steps:

[0027] S1. According to the formula quantity, mix propylene glycol and hydroxyethyl cellulose, stir and disperse evenly, and prepare mixed solution A;

[0028] S2. Add the water in the p...

Embodiment 2

[0031] Embodiment 2, facial cleanser and preparation method thereof of post-foaming of the present invention

[0032] The post-foaming facial cleanser of Example 2 of the present invention is composed of the following components: 16kg of surfactant, 17kg of petrolatum, 8kg of propylene glycol, 2kg of triethanolamine, 10kg of acrylic acid copolymer, trans 1-chloro-3,3,3- Trifluoropropylene 5kg, hydroxyethyl cellulose 0.4kg, p-hydroxyacetophenone 0.5kg, essence 0.4kg, nitrogen 0.7kg and water 40kg.

[0033] The surfactant is sodium cocoyl isethionate, alkyl glucoside and ammonium lauryl sulfate, the sodium cocoyl isethionate, alkyl glycoside and ammonium lauryl sulfate The mass ratio is 1:0.2:0.04.

[0034] The preparation method of described post-foaming facial cleanser, comprises the following steps:

[0035] S1. According to the formula quantity, mix propylene glycol and hydroxyethyl cellulose, stir and disperse evenly, and prepare mixed solution A;

[0036] S2. Add the wa...

Embodiment 3

[0039] Embodiment 3, facial cleanser and preparation method thereof after foaming of the present invention

[0040] The post-foaming facial cleanser of Example 3 of the present invention is composed of the following components: 20kg of surfactant, 15kg of vaseline, 5kg of propylene glycol, 2.5kg of triethanolamine, 6kg of acrylic acid copolymer, and trans 1-chloro-3,3,3 - Trifluoropropene 6 kg, hydroxyethyl cellulose 0.5 kg, p-hydroxyacetophenone 0.7 kg, essence 0.5 kg, nitrogen 1 kg and water 42.8 kg.

[0041] The surfactant is sodium cocoyl isethionate, alkyl glucoside and ammonium lauryl sulfate, the sodium cocoyl isethionate, alkyl glycoside and ammonium lauryl sulfate The mass ratio is 1:0.3:0.05.

[0042] The preparation method of described post-foaming facial cleanser, comprises the following steps:

[0043] S1. According to the formula quantity, mix propylene glycol and hydroxyethyl cellulose, stir and disperse evenly, and prepare mixed solution A;

[0044] S2. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com