Forced blockage-removing mechanism suitable for furrow opener of rice stubble field

A technology of opener and fertilization opener, which is applied in the direction of excavation/covering of trenches, application, agricultural machinery and implements, etc., can solve the problem of not being able to ensure no blockage, etc., and achieve the effect of compact structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

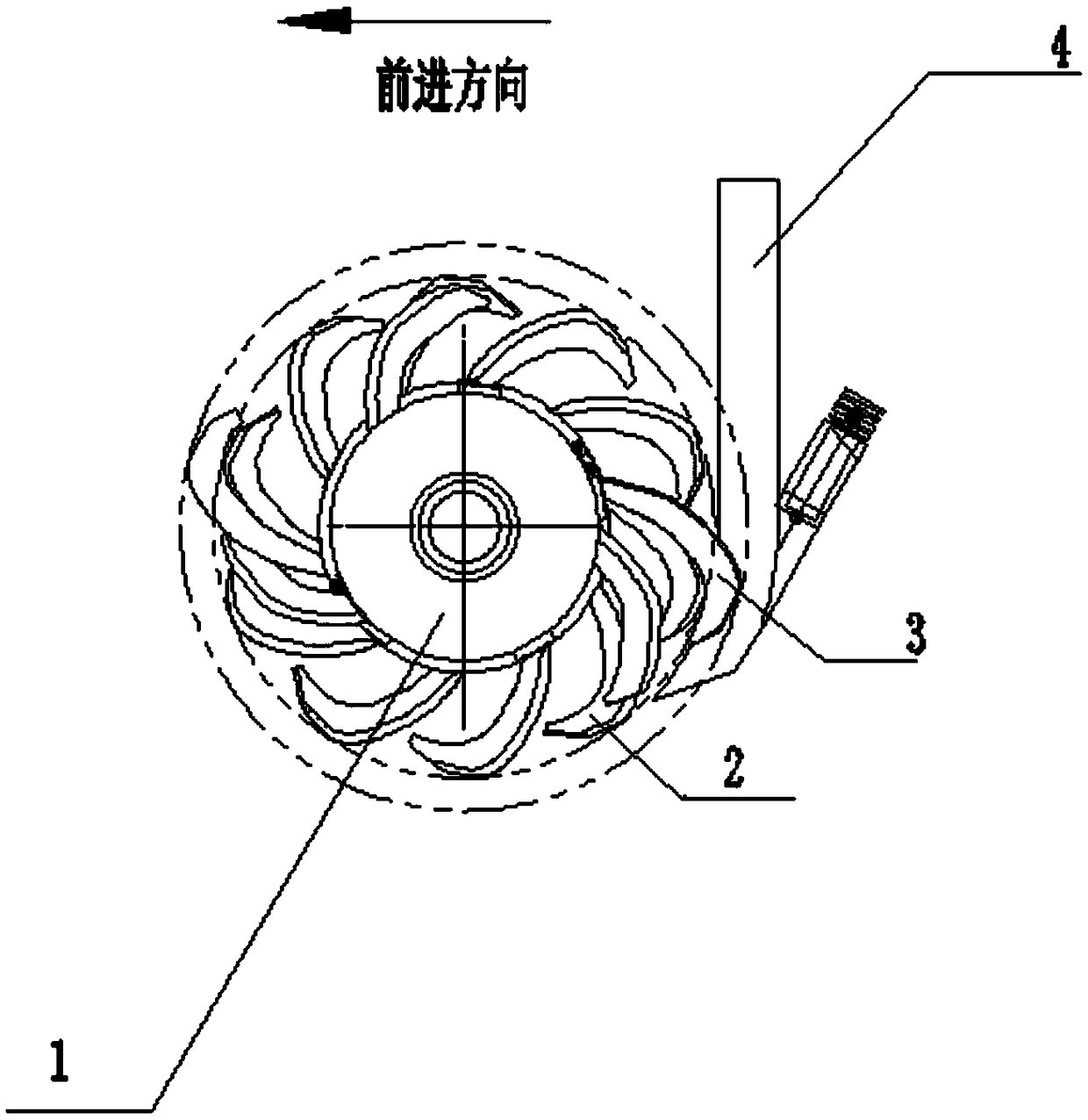

[0027] see Figure 1-Figure 6 , a forced clearing mechanism suitable for ditch openers in rice stubble fields, the rotary tiller 1 is set at the position close to the fertilization ditch opener 4, so that the end of the rotary tiller 2 of the rotary tiller 1 is close to Directly in front of the lower part of the ditch opener, but not in contact; on the rotating shaft of the rotary cultivator 1, several side clearing straight knives 3 are added, and the rotation radius of the outermost end of the straight knives is greater than that of the rotary tiller machete 2 outermost ends, and the side clearing The plugging straight knife 3 is close to one side of the opener, but does not touch.

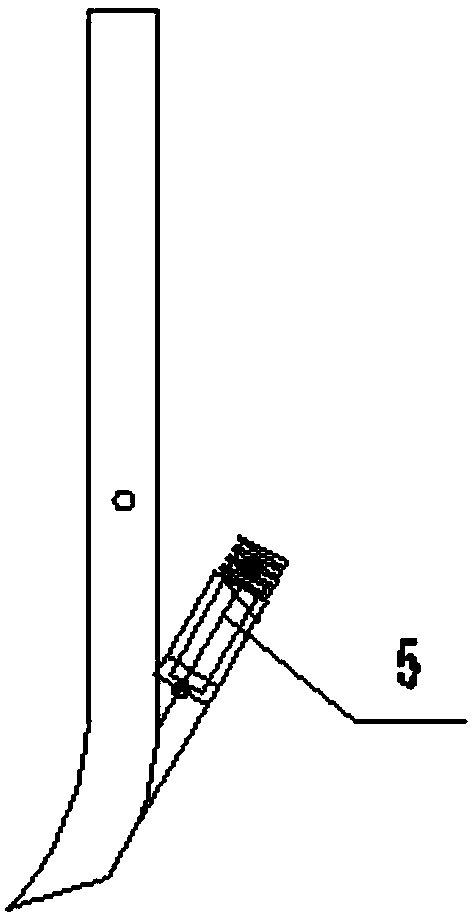

[0028] In this example, see Figure 3-5 , the fertilization ditch opener 4 is hollow, and the fertilization pipe connector 5 is fixedly arranged on the ditch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com