High-temperature-resistance oxygen sensor device

An oxygen sensor and oxygen sensing technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increased line resistance, affecting measurement accuracy, and damaging sensors, so as to reduce the damage rate of operation, prolong the working life, Guarantee the effect of normal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

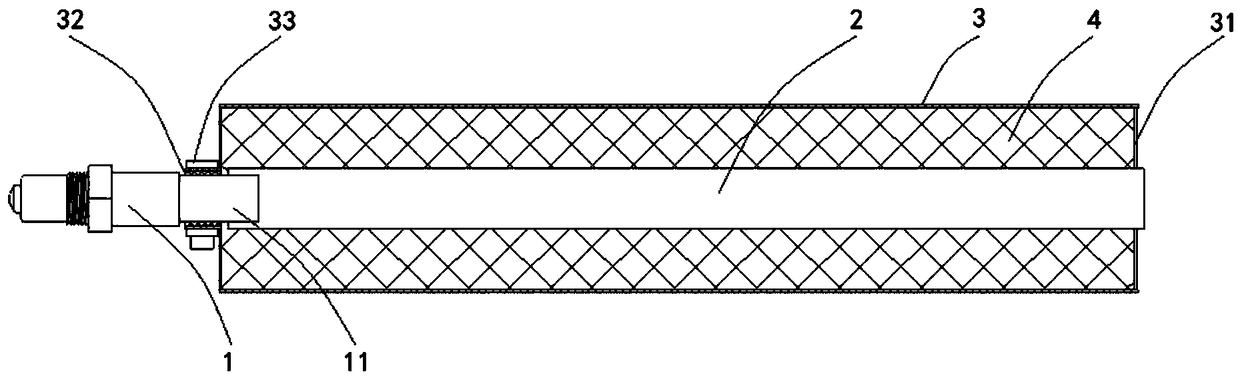

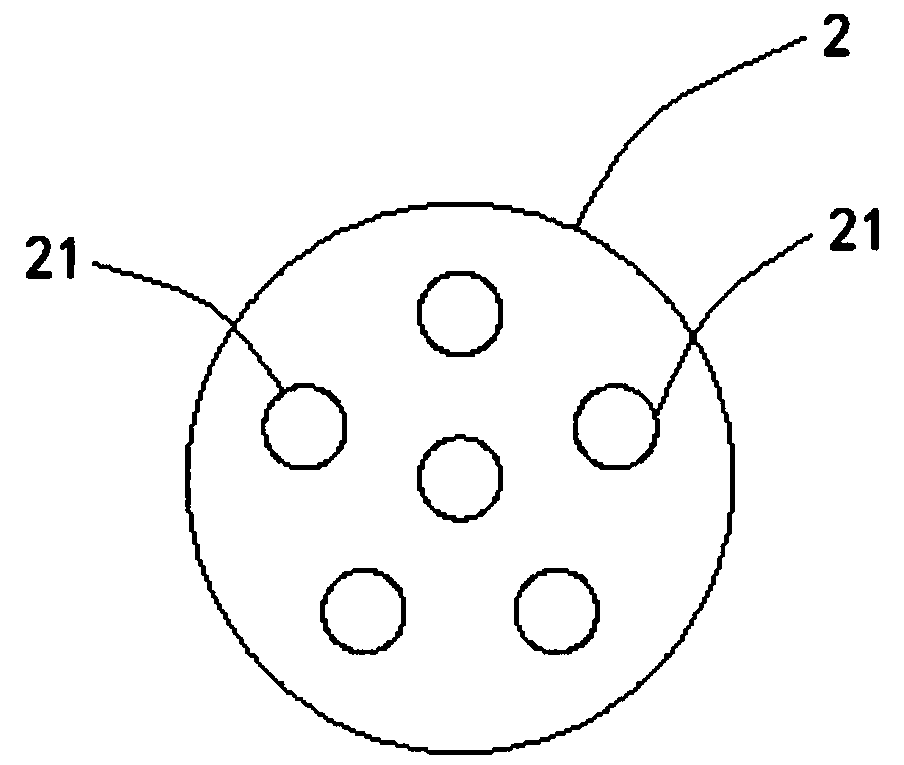

[0030] Such as Figure 1-2 As shown, a high temperature resistant oxygen sensor device of the present invention, the oxygen sensor device includes an oxygen sensor 1, a thermal insulation tube 2 and a protective envelope 3; the output terminal 11 of the oxygen sensor 1 is connected to the isolation One end of the thermal insulation tube 2 is connected, and the protective envelope 3 is sleeved on the outside of the thermal insulation tube 2; the oxygen sensor 1 is the detection body, and one end is connected with multiple cables; the thermal insulation tube 2 is provided with a plurality of through holes 21 along its length direction, and the plurality of cables pass through the plurality of through holes 21 one by o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com